Thick colorful rubber EVA sheets offer both aesthetic appeal and functional benefits in high-traffic areas. To maximize their durability and performance, it’s essential to understand key factors such as material quality, installation methods, and maintenance practices. This guide provides insights into optimizing the longevity of EVA sheets in demanding environments.

Ethylene Vinyl Acetate (EVA) sheets, known for their durability, versatility, and vibrant colors, are an excellent choice for high-traffic areas. Whether used in commercial spaces, educational facilities, or sports venues, thick colorful rubber EVA sheets must withstand constant use while maintaining their appearance and functionality. This article explores how to optimize the durability of these sheets to ensure they perform effectively in high-traffic environments.

1. Choosing the Right EVA Sheet Quality

The quality of EVA sheets significantly impacts their durability. When selecting EVA sheets for high-traffic areas, consider the following factors:

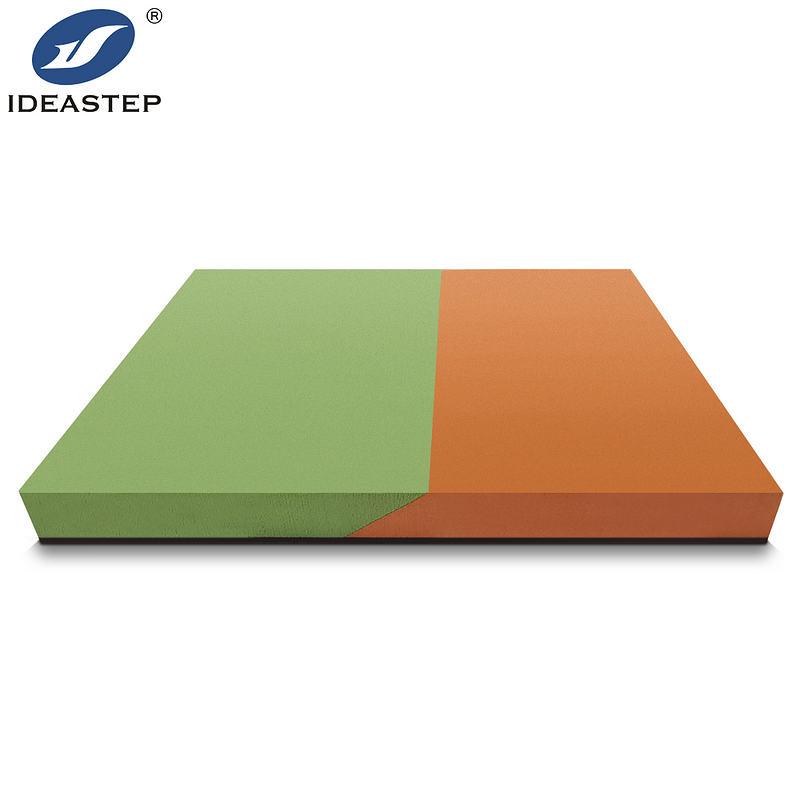

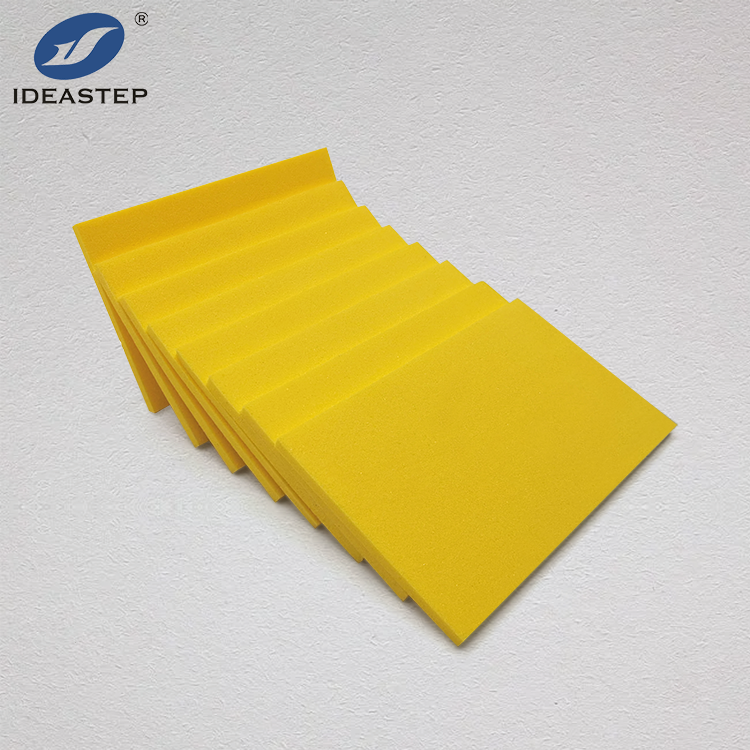

- Thickness: Thicker EVA sheets typically offer better shock absorption and resistance to wear and tear. For high-traffic areas, opt for sheets with a thickness of at least 6–10mm to ensure they can handle heavy foot traffic and impacts.

- Density: Higher density EVA sheets are more resistant to compression and deformation. Check the density specifications provided by the supplier to ensure the sheets can endure the demands of high-traffic zones.

- Color Stability: Choose EVA sheets with UV-stabilized colors to prevent fading and discoloration over time. This ensures that the vibrant appearance of the sheets is maintained despite exposure to sunlight and other environmental factors.

2. Proper Installation Techniques

Correct installation plays a crucial role in enhancing the durability of EVA sheets. Follow these guidelines to ensure a successful installation:

- Surface Preparation: Ensure that the installation surface is clean, dry, and level. Any debris, moisture, or unevenness can affect the adhesion and performance of the EVA sheets.

- Adhesive Selection: Use high-quality adhesive specifically designed for EVA sheets. The adhesive should be compatible with the surface and provide strong, long-lasting bonding to prevent shifting or lifting of the sheets.

- Seam Sealing: Properly seal the seams between EVA sheets to prevent dirt and moisture from penetrating. This can be achieved using seam tape or adhesive specifically designed for EVA materials.

- Professional Installation: Consider hiring professional installers with experience in working with EVA sheets. Professional installation ensures that the sheets are laid correctly and any potential issues are addressed promptly.

3. Regular Maintenance Practices

Ongoing maintenance is essential for preserving the durability and appearance of EVA sheets. Implement these maintenance practices to extend the lifespan of the sheets:

- Cleaning: Regularly clean the EVA sheets using a mild detergent and water. Avoid using harsh chemicals or abrasive cleaners that can damage the surface. Sweep or vacuum the area to remove debris and prevent scratching.

- Spot Repairs: Address any damage or wear promptly to prevent it from worsening. Use EVA-compatible repair kits or patches to fix small tears or gouges in the sheets.

- Inspection: Periodically inspect the sheets for signs of wear, such as flattening or discoloration. Address any issues promptly to prevent further damage and maintain the integrity of the flooring.

- Protective Measures: Place mats or rugs in areas with extreme wear and tear, such as entranceways or heavy machinery zones, to reduce the direct impact on the EVA sheets.

4. Environmental Considerations

Environmental factors can also influence the durability of EVA sheets. Consider the following factors when using EVA sheets in high-traffic areas:

- Temperature Variations: EVA sheets can be sensitive to temperature fluctuations. Ensure that the installation area maintains a stable temperature to prevent warping or deformation of the sheets.

- Moisture Control: High moisture levels can weaken EVA sheets over time. Ensure proper ventilation and control moisture levels in the installation area to prevent damage.

- UV Exposure: Prolonged exposure to UV rays can cause fading and deterioration of EVA sheets. Consider using protective coatings or UV-resistant sheets to mitigate this effect.

Conclusion

Optimizing the durability of thick colorful rubber EVA sheets in high-traffic areas involves selecting high-quality materials, ensuring proper installation, and adhering to regular maintenance practices. By understanding the factors that impact EVA sheet performance and addressing environmental considerations, you can enhance the longevity and functionality of EVA sheets in demanding environments.

FAQ

1. What thickness of EVA sheets is recommended for high-traffic areas?

For high-traffic areas, EVA sheets with a thickness of 6–10mm are recommended. Thicker sheets provide better shock absorption and durability.

2. How often should EVA sheets be cleaned?

EVA sheets should be cleaned regularly, ideally once a week or as needed, using mild detergent and water to maintain their appearance and performance.

3. Can I install EVA sheets myself, or should I hire a professional?

While DIY installation is possible, hiring a professional installer with experience in EVA sheets is recommended to ensure proper placement and avoid potential issues.