When selecting EVA sheets for various applications, understanding the key specifications and features is crucial for ensuring optimal performance and durability. This guide outlines essential factors to consider when choosing EVA sheets to meet your specific needs effectively.

EVA (Ethylene Vinyl Acetate) sheets are versatile materials widely used in industries ranging from footwear and sports equipment to packaging and construction. Their popularity is due to their excellent properties, including flexibility, cushioning, and resistance to impact and moisture. However, not all EVA sheets are created equal, and selecting the right one requires careful consideration of several key specifications and features. This article provides a comprehensive guide on what to look for in EVA sheets to ensure they meet your specific requirements.

1. Thickness and Density

The thickness and density of EVA sheets play a significant role in determining their suitability for different applications. Thickness affects the cushioning and shock absorption properties of the material, while density influences its durability and support. When choosing EVA sheets, consider the following:

- Thickness: EVA sheets come in various thicknesses, ranging from a few millimeters to several centimeters. Thicker sheets offer better cushioning and impact resistance, making them ideal for applications such as footwear insoles and sports mats. Conversely, thinner sheets may be suitable for applications requiring less cushioning but more flexibility.

- Density: The density of EVA sheets is typically measured in grams per cubic centimeter (g/cm³). Higher density sheets are more rigid and provide better support, while lower density sheets are more flexible and offer enhanced cushioning. Choose the density that best aligns with the intended use of the EVA sheets.

2. Compression Set and Resilience

Compression set and resilience are crucial factors that affect the performance and longevity of EVA sheets. Compression set refers to the material’s ability to return to its original shape after being compressed, while resilience measures how well the material recovers from deformation. Consider the following:

- Compression Set: A low compression set indicates that the EVA sheet will maintain its shape and performance even after prolonged use. This is particularly important for applications where the material will be subjected to repeated compression, such as in shoe soles or cushioning pads.

- Resilience: EVA sheets with high resilience recover quickly from deformation and provide consistent performance over time. This characteristic is essential for applications requiring frequent impact absorption or cushioning.

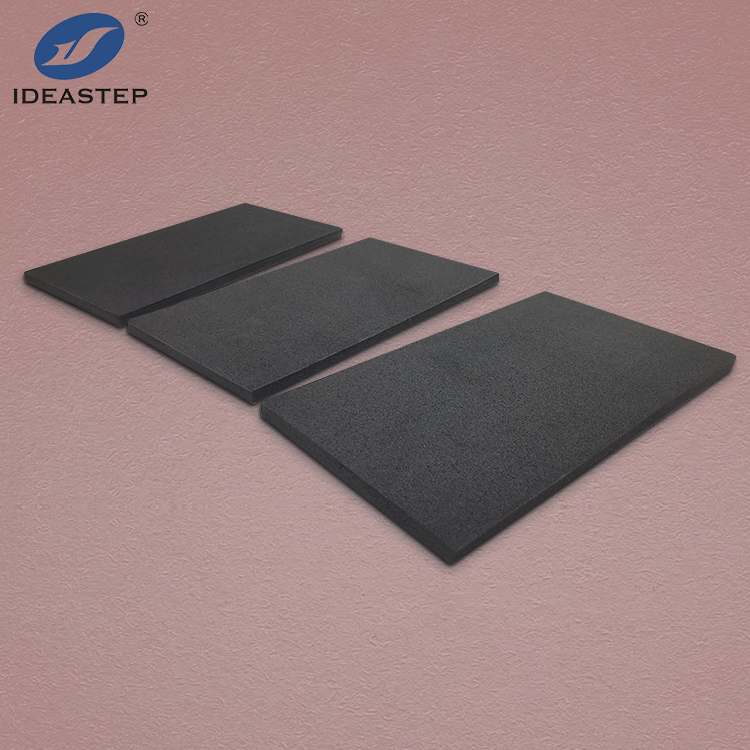

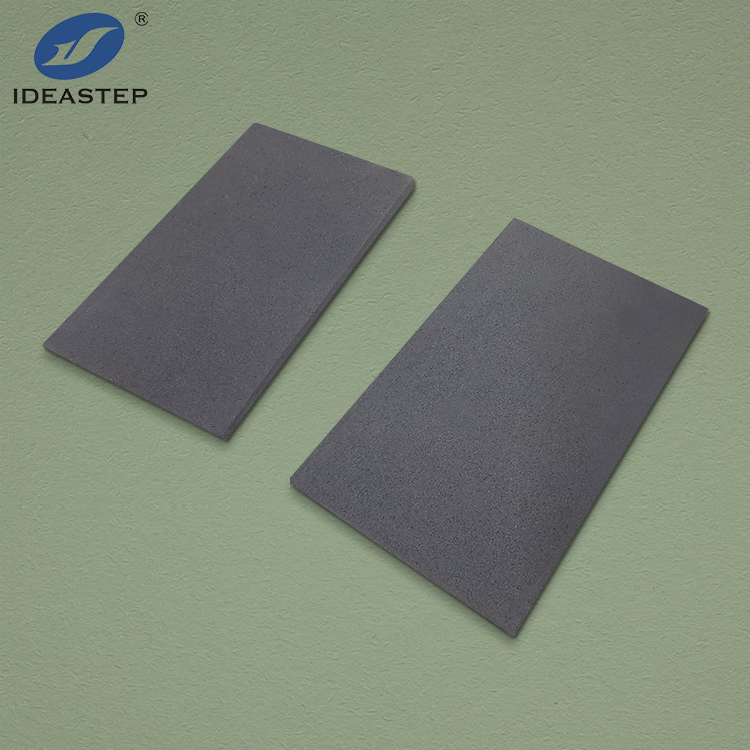

3. Surface Texture and Finish

The surface texture and finish of EVA sheets can impact their functionality and aesthetic appeal. Different textures and finishes are suitable for various applications, including protective coverings, decorative elements, and functional components. Consider the following:

- Surface Texture: EVA sheets can have smooth, textured, or patterned surfaces. Smooth surfaces are often used for applications requiring a clean, polished appearance, while textured or patterned surfaces provide additional grip and traction. Choose the surface texture that best suits your application needs.

- Finish: The finish of EVA sheets can be matte, glossy, or a combination of both. A matte finish reduces glare and provides a more subtle appearance, while a glossy finish enhances the visual appeal and can make cleaning easier. Select the finish based on your specific requirements and aesthetic preferences.

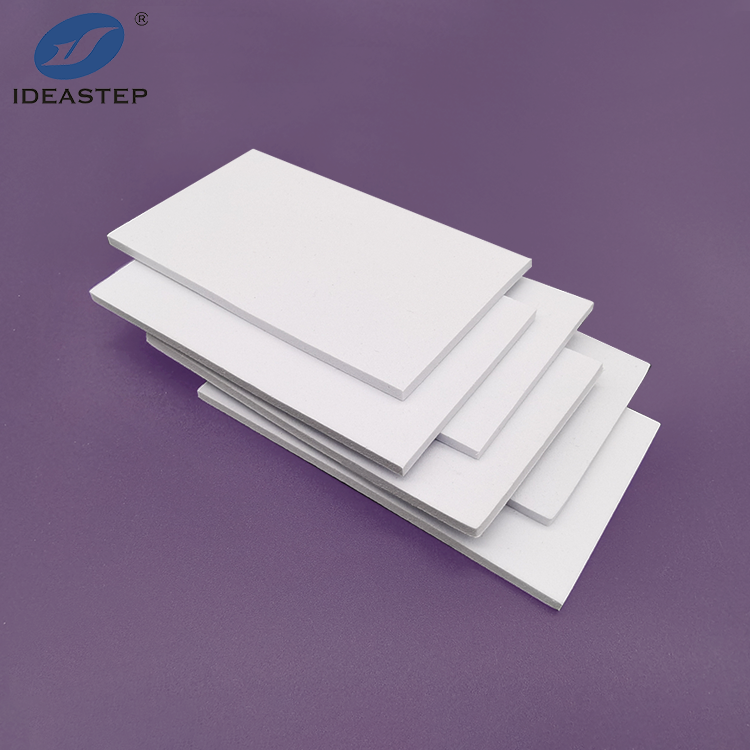

4. Color and Customization

EVA sheets are available in a wide range of colors, and customization options are often available to meet specific design requirements. Consider the following:

- Color: The color of EVA sheets can affect the overall look of the final product and may be chosen based on branding or aesthetic preferences. Some applications may require specific colors for visibility or design purposes.

- Customization: Many suppliers offer customization options, such as cutting, shaping, and printing, to tailor EVA sheets to specific needs. Customization can enhance the functionality and appearance of the material, making it better suited for particular applications.

5. Environmental and Safety Considerations

Environmental and safety considerations are important when selecting EVA sheets, especially for applications involving direct contact with users or sensitive environments. Consider the following:

- Environmental Impact: Look for EVA sheets that are manufactured with environmentally friendly processes and materials. Some suppliers offer recyclable or biodegradable options that reduce environmental impact.

- Safety: Ensure that the EVA sheets comply with relevant safety standards and regulations. This is particularly important for applications such as children’s products or medical devices, where safety is a primary concern.

6. Cost and Supplier Reliability

Finally, consider the cost of EVA sheets and the reliability of the supplier. While it is important to choose high-quality materials, cost considerations also play a significant role in decision-making. Consider the following:

- Cost: Compare the prices of different EVA sheets and suppliers to find the best value for your budget. Keep in mind that higher quality materials may come at a higher cost but can offer better performance and durability.

- Supplier Reliability: Choose a reputable supplier with a track record of delivering high-quality EVA sheets and reliable customer service. A reliable supplier can provide valuable support and ensure timely delivery of materials.

Conclusion

Choosing the right EVA sheets requires careful consideration of key specifications and features, including thickness, density, compression set, resilience, surface texture, finish, color, customization, environmental impact, safety, cost, and supplier reliability. By understanding these factors and selecting the appropriate EVA sheets, businesses can ensure optimal performance and durability for their specific applications.

FAQ

1. What factors should I consider when selecting EVA sheets?

When selecting EVA sheets, consider factors such as thickness, density, compression set, resilience, surface texture, finish, color, customization options, environmental impact, safety, cost, and supplier reliability.

2. How does the thickness of EVA sheets affect their performance?

Thicker EVA sheets offer better cushioning and impact resistance, making them suitable for applications requiring significant shock absorption. Thinner sheets may provide more flexibility but less cushioning.

3. Why is it important to choose a reliable supplier for EVA sheets?

A reliable supplier ensures the delivery of high-quality EVA sheets and provides valuable support and timely delivery. This helps in maintaining consistent product performance and avoiding disruptions.