EVA CAD CAM milling blocks are revolutionizing customized footwear design by offering unparalleled precision, flexibility, and efficiency. This article explores the key features that make these blocks ideal for tailoring footwear to individual needs.

Understanding EVA CAD CAM Milling Blocks

EVA (Ethylene Vinyl Acetate) CAD CAM milling blocks are advanced materials designed specifically for computer-aided design (CAD) and computer-aided manufacturing (CAM) processes in footwear production. These blocks are used to create precise and customized footwear components, providing designers and manufacturers with greater control and flexibility in the design process.

Key Features of EVA CAD CAM Milling Blocks

Several features make EVA CAD CAM milling blocks particularly suitable for customized footwear design:

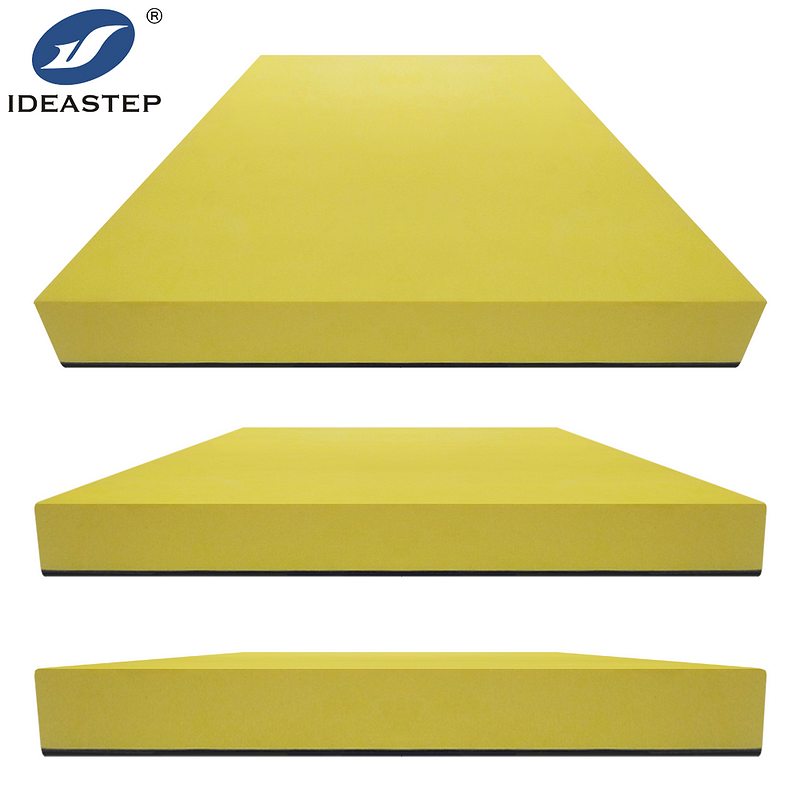

1. Precision and Accuracy

EVA milling blocks are engineered to offer exceptional precision and accuracy. The material’s consistency allows for detailed and intricate designs to be produced with high fidelity. This precision is crucial for ensuring that the final footwear product matches the designer’s specifications exactly, enhancing both fit and comfort.

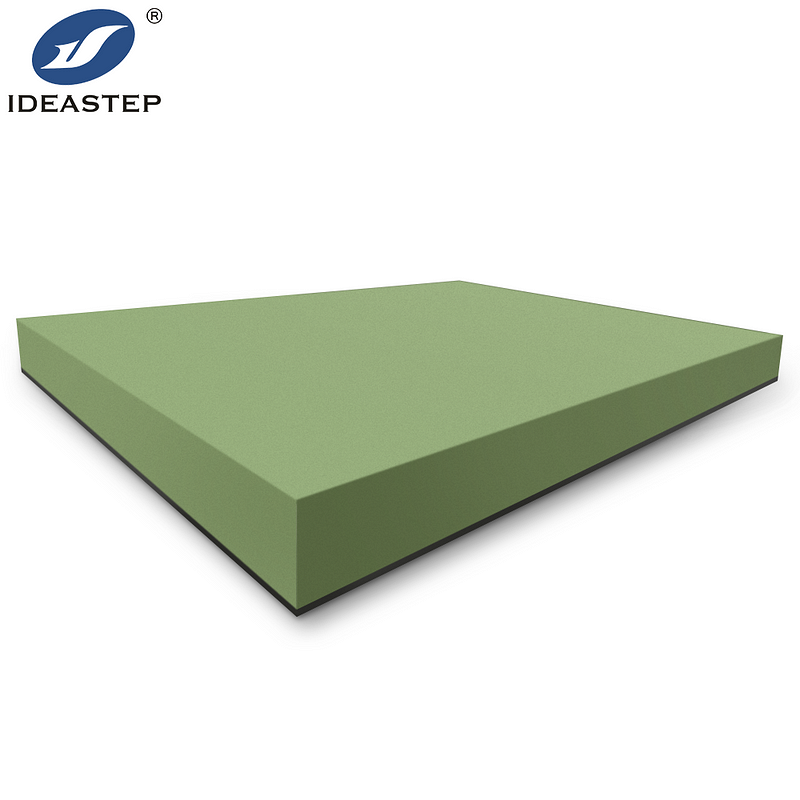

2. Lightweight and Durable

One of the main advantages of EVA is its lightweight nature combined with durability. EVA blocks provide a strong, resilient material that maintains its form and function over time, while being light enough to contribute to a comfortable footwear design. This balance of weight and durability is ideal for producing long-lasting, high-performance footwear.

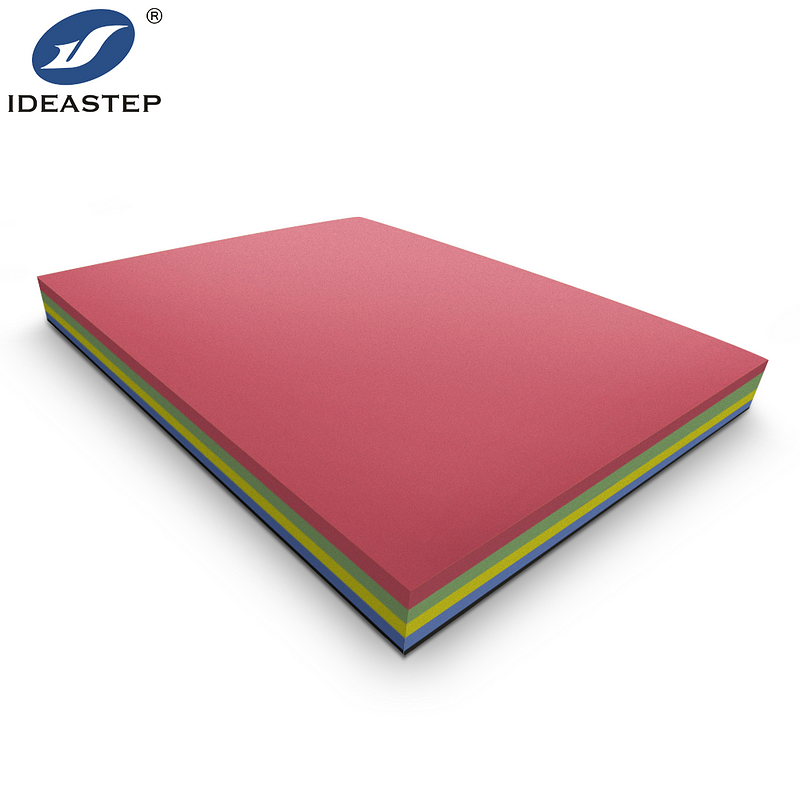

3. Flexibility and Customization

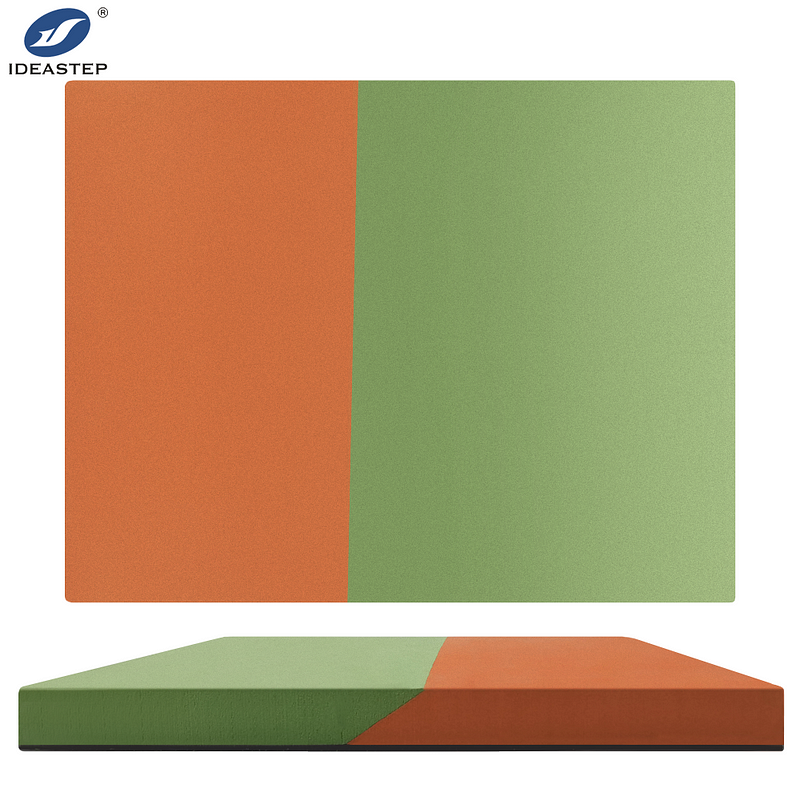

EVA CAD CAM milling blocks are highly flexible, allowing for a wide range of designs and modifications. Whether it’s creating unique patterns, intricate textures, or complex shapes, EVA’s adaptability ensures that designers can experiment with various styles and features. This flexibility is especially beneficial for custom and bespoke footwear projects, where unique designs are a key requirement.

Advantages in Footwear Design

Utilizing EVA CAD CAM milling blocks offers several advantages in the footwear design process:

1. Enhanced Design Freedom

With EVA milling blocks, designers have the freedom to explore innovative design concepts. The material’s flexibility allows for the creation of custom soles, insoles, and other components with intricate details that might be difficult to achieve with traditional materials.

2. Improved Production Efficiency

The use of CAD CAM technology in conjunction with EVA blocks streamlines the production process. Automated milling and precise cutting reduce manual labor and minimize errors, leading to faster turnaround times and more consistent product quality. This efficiency is particularly beneficial for high-volume production runs where speed and accuracy are crucial.

3. Cost-Effective Prototyping

Prototyping with EVA CAD CAM milling blocks is cost-effective compared to traditional methods. The ability to quickly produce and test multiple prototypes allows designers to iterate and refine their designs without incurring significant costs. This rapid prototyping capability accelerates the design process and enables more efficient product development.

Applications in Customized Footwear

EVA CAD CAM milling blocks are used in various aspects of customized footwear design:

1. Custom Insoles and Orthotics

Designers and manufacturers use EVA milling blocks to create custom insoles and orthotics tailored to individual foot shapes and needs. The precision of CAD CAM milling ensures a perfect fit, improving comfort and support for users with specific requirements.

2. Unique Shoe Soles

EVA’s flexibility and durability make it an excellent choice for crafting unique and performance-enhancing shoe soles. Designers can experiment with different tread patterns, cushioning levels, and ergonomic features to create soles that provide optimal performance and comfort.

3. Bespoke Footwear Components

Custom footwear projects often require bespoke components, such as custom heels or specialized design elements. EVA CAD CAM milling blocks allow for the creation of these components with high precision, ensuring that they fit seamlessly with the rest of the footwear design.

Challenges and Considerations

While EVA CAD CAM milling blocks offer numerous benefits, there are also challenges to consider:

1. Material Costs

High-quality EVA milling blocks can be costly, which may impact the overall budget for footwear projects. Balancing material costs with project requirements is essential to ensure cost-effectiveness without compromising on quality.

2. Machine Compatibility

Not all milling machines are compatible with EVA blocks. Ensuring that your CAD CAM equipment is suitable for processing EVA material is crucial to avoid issues during production.

3. Skill Requirements

Effective use of CAD CAM technology requires skilled operators who are proficient in both software and hardware. Investing in training and expertise is necessary to fully leverage the capabilities of EVA milling blocks.

Conclusion

EVA CAD CAM milling blocks offer significant advantages for customized footwear design, including precision, lightweight durability, and flexibility. By integrating these blocks into the design and manufacturing process, footwear designers can achieve greater innovation, efficiency, and cost-effectiveness. Despite some challenges, the benefits of EVA milling blocks make them an ideal choice for creating high-quality, customized footwear solutions.

FAQ

1. What is EVA CAD CAM milling?

EVA CAD CAM milling involves using computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies to create precise footwear components from EVA foam blocks.

2. What are the main advantages of using EVA blocks for footwear design?

EVA blocks provide precision, lightweight durability, and flexibility, which enhance design freedom, improve production efficiency, and enable cost-effective prototyping.

3. Are there any challenges associated with using EVA CAD CAM milling blocks?

Challenges include material costs, machine compatibility, and the need for skilled operators to effectively use CAD CAM technology.