Evaluating the durability and performance of EVA sheets before making a purchase is crucial for ensuring that you select the best product for your needs. This guide provides essential insights into assessing these aspects effectively.

Understanding EVA Sheets

EVA (Ethylene Vinyl Acetate) sheets are versatile materials widely used across various industries for their flexibility, durability, and lightweight properties. They are commonly employed in applications ranging from footwear to packaging and protective gear. To ensure that you are investing in high-quality EVA sheets, it’s important to assess their durability and performance thoroughly before making a purchase.

1. Check the Material Composition

The composition of EVA sheets can significantly impact their performance and durability. High-quality EVA sheets typically contain a higher proportion of ethylene, which enhances their strength and flexibility. Verify the material composition by checking the product specifications or requesting a sample from the supplier. Trusted suppliers, such as Ideastep, often provide detailed information about their products to help you make an informed decision.

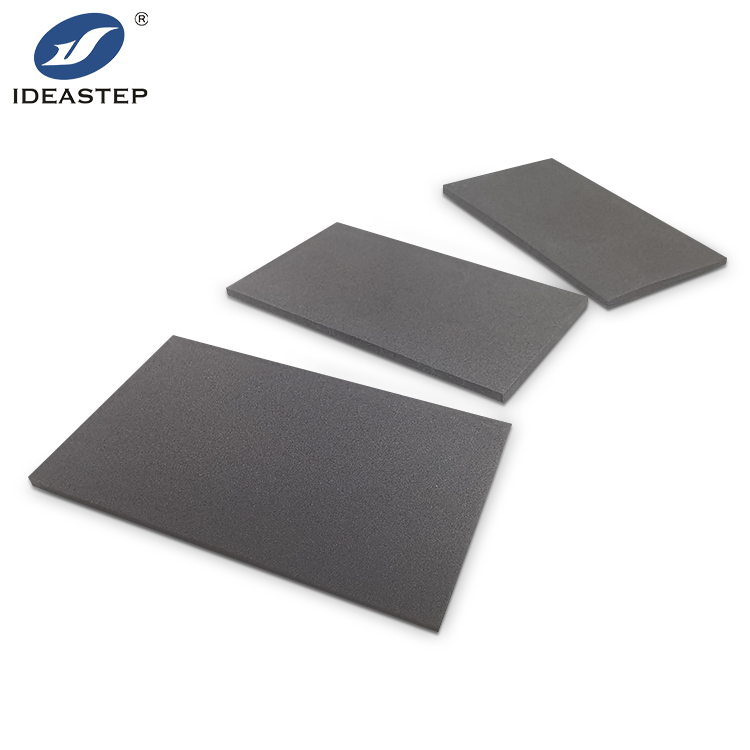

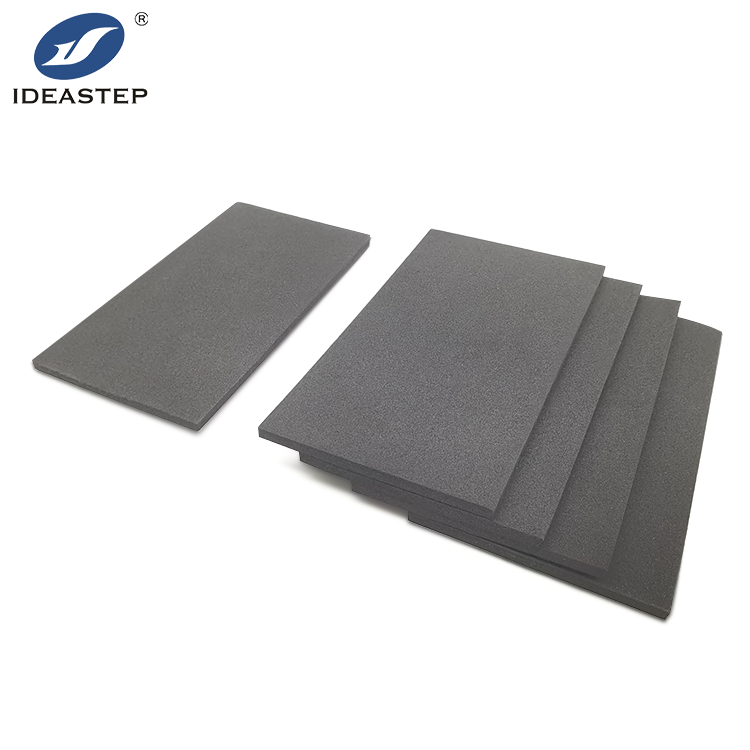

2. Assess the Thickness and Density

The thickness and density of EVA sheets are crucial factors that influence their performance. Thicker sheets generally offer better cushioning and impact resistance, while denser sheets provide enhanced durability. When evaluating EVA sheets, consider the specific requirements of your application and choose a thickness and density that meet those needs. For example, footwear applications might require thicker, denser sheets for improved comfort and support.

3. Evaluate the Durability Through Testing

Durability testing is essential to gauge how well EVA sheets will perform under various conditions. Common tests include measuring the sheet’s resistance to abrasion, compression, and environmental factors such as UV exposure and moisture. Requesting test results or certifications from the supplier can provide insights into the sheet’s long-term performance. Reputable suppliers like Ideastep often conduct rigorous testing to ensure their products meet high standards.

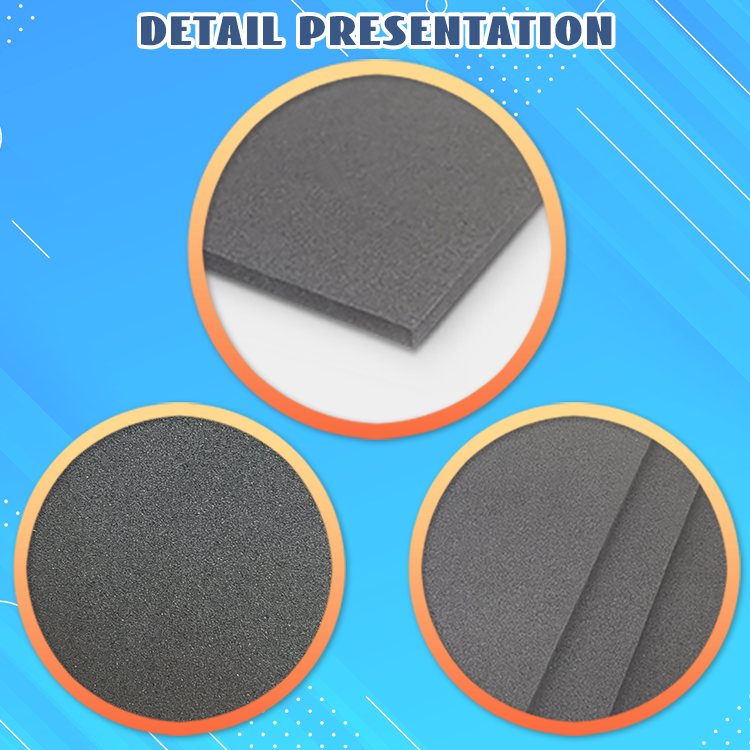

4. Consider the Flexibility and Compression Set

Flexibility and compression set are important attributes that determine how EVA sheets will perform under stress. Flexibility refers to the material’s ability to bend without cracking, while compression set measures the material’s ability to return to its original shape after being compressed. Test these attributes by evaluating product samples or consulting with suppliers about their performance metrics. This information helps ensure that the EVA sheets will maintain their shape and functionality over time.

5. Examine the Surface Quality

The surface quality of EVA sheets can affect their overall performance and aesthetic appeal. Look for sheets with a smooth, even surface that is free of defects such as bubbles, wrinkles, or uneven texture. A high-quality surface ensures better adhesion and a more professional finish for applications where appearance matters. Suppliers like Ideastep often provide samples for inspection to help you assess the surface quality before purchase.

6. Review Customer Feedback and Reviews

Customer feedback and reviews can offer valuable insights into the performance and durability of EVA sheets. Look for reviews from customers who have used the sheets in similar applications to yours. Positive reviews and high ratings can indicate a reliable product, while negative feedback may signal potential issues. Reputable suppliers often have customer testimonials available on their websites, providing further assurance of their products’ quality.

7. Compare Prices and Warranties

While price is an important consideration, it should not be the sole factor in your decision. Compare prices among different suppliers, including Ideastep, to ensure you are getting a fair deal. Additionally, check for warranties or guarantees offered by the supplier. A warranty can provide peace of mind and protection against potential defects or performance issues.

Conclusion

Assessing the durability and performance of EVA sheets before purchase involves evaluating material composition, thickness, density, flexibility, compression set, surface quality, and customer feedback. By considering these factors and consulting with reputable suppliers, you can make an informed decision and select EVA sheets that meet your needs effectively. Investing time in this evaluation process will help ensure that your chosen sheets offer long-lasting performance and value.

FAQ

1. What is the difference between EVA sheets and other types of foam?

EVA sheets differ from other types of foam in their composition and properties. EVA foam is known for its flexibility, durability, and lightweight nature. Unlike some other foams, EVA does not absorb water, making it suitable for applications where moisture resistance is important. Additionally, EVA sheets offer excellent cushioning and impact resistance compared to other materials.

2. How can I test the flexibility of EVA sheets?

To test the flexibility of EVA sheets, bend the material to observe how well it flexes without cracking or breaking. You can also perform a stress test by applying pressure to see how the sheet responds. High-quality EVA sheets should demonstrate good flexibility and maintain their shape under stress.

3. Are there any environmental considerations when using EVA sheets?

EVA sheets are generally considered to be more environmentally friendly compared to some other materials. They do not contain harmful chemicals like PVC and are often recyclable. However, it’s important to check with suppliers about their specific environmental policies and recycling options to ensure that you are making a sustainable choice.