To achieve the desired product quality and functionality, it is essential to select the appropriate EVA sheets for your manufacturing requirements. This guide provides key considerations and tips for choosing the most suitable EVA sheets, ensuring that they meet your specific needs and enhance your manufacturing processes.

Introduction to EVA Sheets

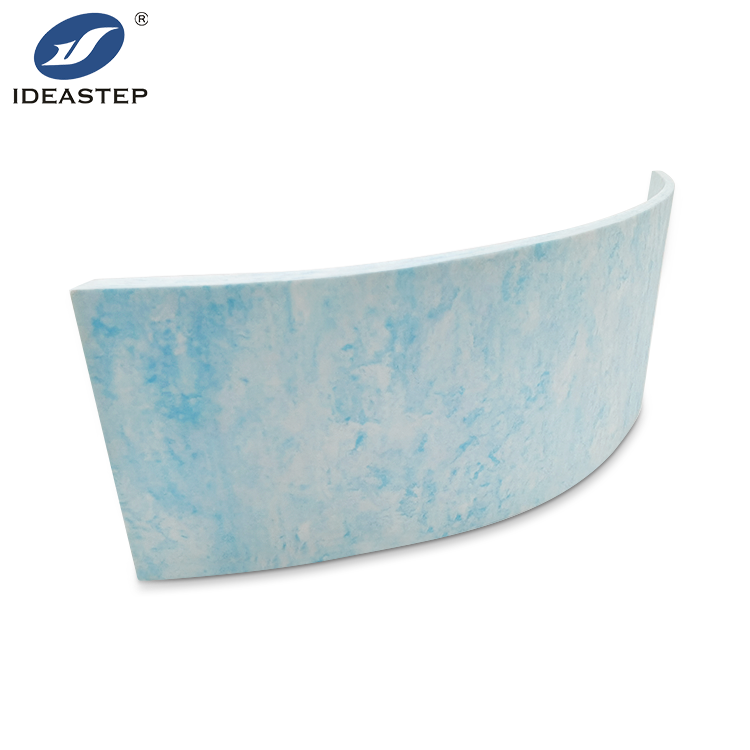

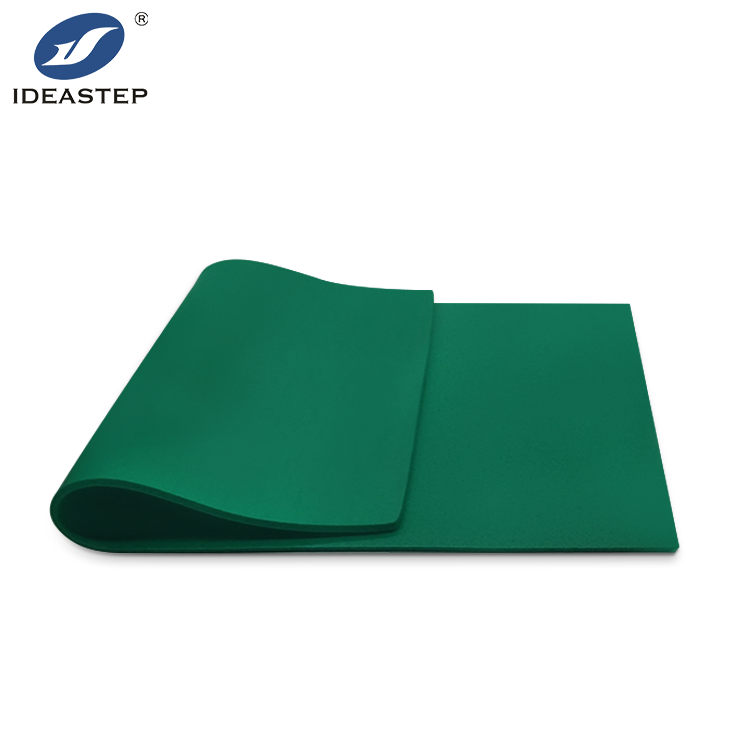

Ethylene-vinyl acetate (EVA) sheets are a popular material used in various manufacturing applications due to their adaptability, durability, and ease of processing. EVA sheets come in different thicknesses, densities, and colors, making them suitable for a wide range of uses, from cushioning and insulation to packaging and design elements. Choosing the right EVA sheets is essential for optimizing performance and ensuring product quality.

Factors to Consider When Choosing EVA Sheets

To select the most appropriate EVA sheets for your manufacturing needs, consider the following key factors:

1. Application Requirements

Identify the specific requirements of your application to determine the type of EVA sheets you need. Consider the following:

- Purpose: What will the EVA sheets be used for? Applications could include cushioning, insulation, packaging, or decorative elements.

- Performance Characteristics: Determine the necessary characteristics, such as flexibility, thermal insulation, or resistance to impact.

- Environmental Conditions: Take into account the conditions the sheets will be exposed to, such as temperature fluctuations, humidity, or ultraviolet light.

2. Thickness and Density

The performance and suitability of EVA sheets for various applications are influenced by their thickness and density:

- Thickness: Thicker EVA sheets provide more cushioning and insulation but may be less flexible. Decide on the thickness based on the level of protection or comfort you need.

- Density: EVA sheets with a higher density are more durable and resistant to impacts. For applications requiring solid support, opt for higher density sheets.

3. Aesthetics and Color

The color of your product can have a significant impact on its visual appeal:

- Color Options: EVA sheets are available in a wide range of colors. Choose colors that align with your branding or design requirements.

- Aesthetics: Consider whether the appearance of the EVA sheets needs to complement other materials or design elements in your product.

4. Material Properties

Evaluate the key material properties of EVA sheets to ensure they meet your needs:

- Flexibility: Assess the flexibility of the sheets based on how they will be used. EVA sheets should be flexible enough not to crack when bent or shaped.

- Compression Set: Check the EVA sheets’ compression set to see how well they maintain their shape after being compressed. This is important for cushioning applications.

- Resistance: Consider resistance to chemicals, oils, and other substances that might come into contact with the EVA sheets.

5. Supplier Quality and Reliability

Select a reputable supplier to ensure the quality and reliability of EVA sheets:

- Supplier Reputation: Check reviews and the reputation of potential suppliers. Reliable suppliers should have a track record of delivering high-quality products.

- Certifications: Verify if the supplier’s EVA sheets meet industry standards and certifications, such as ISO or ASTM standards, to ensure quality and safety.

- Sample Testing: Request samples of EVA sheets to test their suitability for your application before making a bulk purchase.

Testing and Evaluation

It is important to test and evaluate the EVA sheets before placing a large order:

- Performance Testing: Conduct performance tests to determine if the sheets are suitable for your application. This may include testing for impact resistance, compression, or thermal insulation.

- Compatibility: Ensure that the EVA sheets are compatible with other materials or components used in your product.

- Durability Testing: Assess the long-term durability of the EVA sheets under expected usage conditions.

Conclusion

Understanding the application requirements, selecting the appropriate thickness and density, considering color and aesthetics, evaluating material properties, and choosing a reliable supplier are all necessary steps in selecting the right EVA sheets for your manufacturing needs. By carefully considering these factors, you can ensure that your EVA sheets meet your specific requirements and contribute to the overall quality and performance of your products.

FAQ

When selecting EVA sheets for my application, what considerations should I make?

Consider the application requirements, thickness and density, color and aesthetics, material properties, and supplier quality and reliability.

How do thickness and density influence EVA sheets?

Thickness affects cushioning and insulation properties, while density impacts durability and impact resistance. Make your decision based on the specific support or protection you require.

Why is it important to test EVA sheets before buying in bulk?

Testing ensures that the EVA sheets meet your performance, compatibility, and durability requirements, helping to avoid issues with large orders.