What Are the Most Effective Uses of EVA Foam Sheet Rolls in Manufacturing?

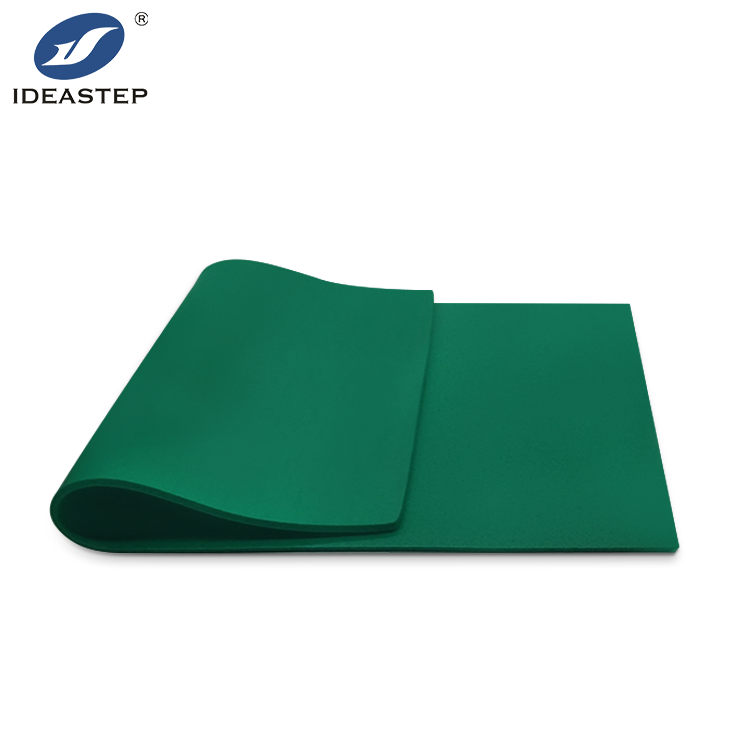

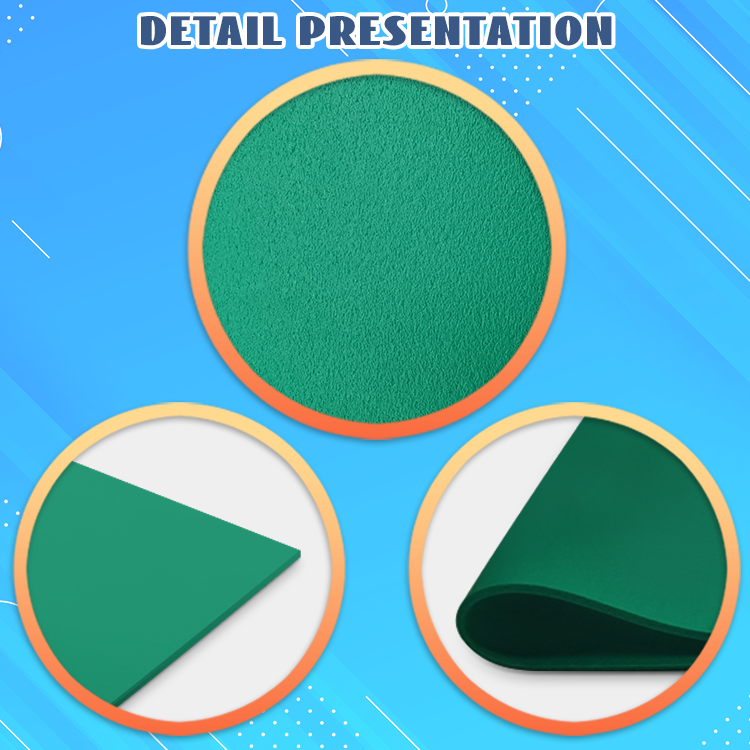

EVA foam sheet is a popular manufacturing material due to its versatility, durability, and waterproofing. Ethylene vinyl acetate foam rollers are utilized in a variety of industries, including packaging and the automotive industry. If manufacturers are aware of the best ways to utilize EVA foam sheets, they will be able to optimize production processes and enhance product performance.

1. EVA Foam Sheets for Packaging and Cushioning

EVA foam sheets are most frequently used for buffering and wrapping. Due to its excellent vibration properties, this foam is ideal for protecting delicate items during shipping and handling. EVA foam is more resistant to impacts and vibrations, despite its lightness and strength. This application is very helpful for:

- Electronic Product Packaging: EVA foam is used to protect laptops, smartphones, and other electronic devices. It helps protect delicate parts from harm thanks to its anti-aging properties.

- Custom Inserts: EVA foam is frequently used by manufacturers to create individualized inserts for boxes and cases. Because these inserts can hold things in place, they are less likely to move or break.

2. EVA Foam Sheet Rolls in Automotive Applications

EVA foam sheet rolls are used in a variety of automotive applications due to their durability and sound characteristics. The following are the most common uses:

- Sound Insulation: EVA foam helps to reduce internal noise and effectively absorb sound. It is applied to automobile doors, dashboards, and floor mats to create a quiet driving environment.

- Gaskets and Seals: EVA foam gaskets and seals are used to stop leaks and vibrations. Due to its adaptability and strength, compression is ideal for securing seals between vehicle components.

3. EVA Foam in Fitness and Sports Equipment

EVA foam is frequently used in fitness and sports equipment due to its high absorbency and simple application. Some examples are:

- Yoga Mats: Due to its capacity to provide cushioning, EVA foam is an excellent material for yoga mats. It provides a comfortable surface for movement and excellent support for protecting the joints.

- Protective Gear: EVA foam is used to make knee pads, elbow pads, and helmet pads. Athletes who participate in high-intensity activities are better protected from harm due to its shock-absorbing qualities.

4. EVA Foam in Construction and Building Materials

Additionally, building and construction materials make use of EVA foam sheets. It is great for:

- Insulation: EVA foam is utilized as building insulation due to its heat resistance. By preventing heat loss or gain, this contributes to maintaining indoor temperatures.

- Flooring: EVA foam is used to create a soft, comfortable, and easy-to-clean surface in interlocking tiles and floor mats.

5. EVA Foam in Consumer Goods

The consumer goods industry can benefit from EVA foam sheets in a number of ways:

- Footwear: EVA foam is often used in shoes because it is light and flexible. It lasts for a long time, is comfortable, and takes pressure off the feet.

- Crafts and DIY Projects: EVA foam is popular in crafts due to its ease of cutting, shaping, and gluing. This material is adored by DIYers and hobbyists for various creative projects.

6. Medical Applications of EVA Foam

EVA foam padding is safe and can be used in the medical field for:

- Orthopedic Supports: EVA foam is used to make braces and orthopedic supports. It provides good support and cushioning for various body parts.

- Medical Cushions: EVA foam is used in cushions for hospital beds and wheelchair floors to provide comfort and alleviate pressure for patients.

Best Practices for Using EVA Foam Sheet Rolls

To get the most out of your sheets, follow these best practices when using EVA foam sheet rollers:

- Proper Storage: Keep EVA foam rollers out of direct sunlight and in a cool, dry place to prevent their degradation. Proper storage ensures the foam maintains its properties over time.

- Cutting and Shaping: Use appropriate tools to cut and shape the EVA foam to fit your needs. This ensures that your application will function flawlessly.

- Continuous Quality Assurance: Regularly check the quality of EVA foam panels to ensure they meet the required standards. Consistent testing helps maintain high performance and reliability in the finished product.

Conclusion

There are numerous manufacturing applications for EVA foam sheet rolls, such as in engineering, packaging, consumer goods, sports equipment, and more. Due to their adaptability, durability, and waterproofing capabilities, EVA foam sheets are ideal for a wide range of industries. By understanding and implementing best practices for EVA foam, manufacturers can improve the performance and longevity of their products.

FAQ

Q: What are the primary benefits of using EVA foam sheet rolls?

A: EVA foam sheet rolls are lightweight, flexible, durable, and versatile. These advantages make them suitable for applications such as sports equipment, packaging, automotive parts, and more.

Q: Can EVA foam be customized to meet specific requirements?

A: Yes, EVA foam can be customized in terms of density, thickness, and shape to meet specific application needs. Custom cutting and shaping can enhance performance for various uses.

Q: How should EVA foam sheets be stored?

A: EVA foam sheets should be stored in a cool, dry place away from direct sunlight. Proper storage helps maintain the foam’s properties and extends its usability.