Rundown: Dominating the procedures for cutting and molding thick vivid elastic EVA sheets is fundamental for accomplishing accuracy and quality in custom applications. This article gives best practices to working with these adaptable materials, zeroing in on devices, strategies, and tips to guarantee viable outcomes in different tasks.

Prologue to Elastic EVA Sheets

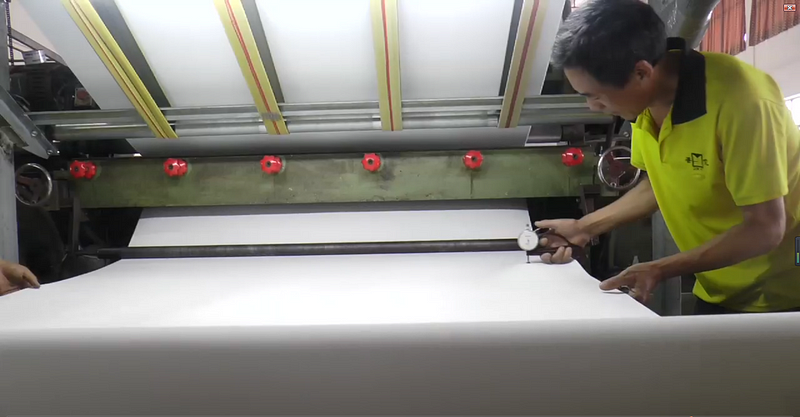

Elastic EVA (Ethylene Vinyl Acetate) sheets are famous for their adaptability, sturdiness, and energetic variety choices. These sheets are normally utilized in various custom applications, including modern, specialty, and configuration projects. Appropriately cutting and molding these thick sheets requires explicit strategies and apparatuses to guarantee exactness and productivity. Understanding these accepted procedures can incredibly upgrade the result of your undertakings.

Apparatuses and Gear for Cutting EVA Sheets

Cutting Apparatuses

While working with thick elastic EVA sheets, it is vital to choose the right cutting instruments. Here are the absolute best apparatuses:

- Utility Blade: For straight cuts and more modest tasks, a sharp utility blade with a retractable cutting edge is great. Try to utilize a new, sharp edge to accomplish clean cuts.

- Turning Shaper: For additional complex or bended cuts, a rotating shaper can be profoundly viable. This device takes into consideration smooth, exact cutting of thick EVA sheets.

- Electric Cutting Machine: For enormous scope or tedious cuts, an electric cutting machine can save time and exertion. These machines give reliable outcomes and are reasonable for high-volume errands.

Cutting Mats and Supports

Utilizing cutting mats or supports is essential to safeguard surfaces and guarantee precise cuts. A self-mending cutting mat can absorb the effect of the sharp edge, forestalling harm to the work surface and drawing out the existence of your edges.

Procedures for Molding EVA Sheets

Utilizing Formats

Making or utilizing formats can help in accomplishing exact shapes and sizes. Layouts can be produced using cardboard or other solid materials and put on the EVA sheet as an aide. This strategy guarantees consistency and diminishes the gamble of blunders.

Heat Forming

Thick EVA sheets can be formed utilizing heat. Applying heat with an intensity weapon or a stove can make the material more malleable, permitting you to form it into various shapes. Be wary of the temperature to abstain from overheating, which can harm the material.

Edge Wrapping up

In the wake of cutting and molding, it’s fundamental for finish the edges to guarantee a smooth and expert appearance. Sanding or managing the edges can eliminate any unpleasant spots and give a perfect completion. For bright EVA sheets, a fine-coarseness sandpaper or a document can be utilized to try not to harm the surface.

Ways to Work with Thick Brilliant EVA Sheets

Variety Consistency

While working with brilliant EVA sheets, guarantee that the varieties match across various sheets and clumps. Varieties in variety can happen, so it’s gainful to work with a solitary bunch of sheets or check variety consistency prior to beginning a venture.

Cement Application

Assuming your venture includes holding EVA sheets together or to different materials, pick a cement that is viable with EVA froth. Splash cements or explicit EVA glues serious areas of strength for give and are not difficult to apply.

Security Safeguards

Continuously keep security rules while cutting and molding EVA sheets. Wear defensive gloves and eyewear to keep wounds from sharp devices or unplanned cuts. Appropriate ventilation is additionally suggested in the event that you’re utilizing heat, to try not to breathe in exhaust.

Normal Uses of Formed EVA Sheets

Custom Bundling

Molded EVA sheets are generally utilized in custom bundling to give padding and security to sensitive things. The capacity to cut and shape these sheets takes into consideration customized arrangements that fit explicit item aspects.

Makes and Do-It-Yourself Ventures

In making and Do-It-Yourself projects, bright EVA sheets can be cut into different shapes and sizes for embellishments, instructive apparatuses, and then some. The flexibility and simplicity of molding pursue EVA froth a famous decision for innovative tasks.

Modern Applications

Thick EVA sheets are additionally utilized in modern applications, including gaskets, seals, and padding. Legitimate slicing and molding are fundamental to guarantee that these parts perform really in their planned jobs.

End

Dominating the prescribed procedures for cutting and molding thick brilliant elastic EVA sheets can fundamentally improve the quality and accuracy of your custom applications. By choosing the right devices, utilizing compelling strategies, and following wellbeing precautionary measures, you can accomplish phenomenal outcomes in your ventures. For excellent EVA sheets and master direction, consider collaborating with legitimate providers like Ideastep to guarantee you get the best materials and backing for your requirements.

FAQ

Q1: What apparatuses are best for cutting thick EVA sheets?

A1: Utility blades, turning cutters, and electric cutting machines are powerful for cutting thick EVA sheets. The decision of hardware relies upon the intricacy and size of your task.

Q2: How might I guarantee variety consistency while utilizing bright EVA sheets?

A2: To guarantee variety consistency, work with sheets from a similar cluster or confirm colors prior to beginning. Reliable variety matching across sheets is fundamental for consistency in your undertaking.

Q3: What security safeguards would it be a good idea for me to take while working with EVA sheets?

A3: Wear defensive gloves and eyewear, utilize sharp apparatuses cautiously, and guarantee legitimate ventilation if utilizing heat. Following these precautionary measures forestalls wounds and guarantees a protected work space.