Best Practices for Using EVA Sheets in Industrial Applications

Basically, EVA sheets have been an essential component in many industries due to their flexibility, durability, and cost. If you are involved in manufacturing or construction, knowing the best ways of using EVA sheets will help optimize performance and assure longevity to your projects. Here’s a detailed guide on how to utilize EVA sheets in industrial settings to their full potential.

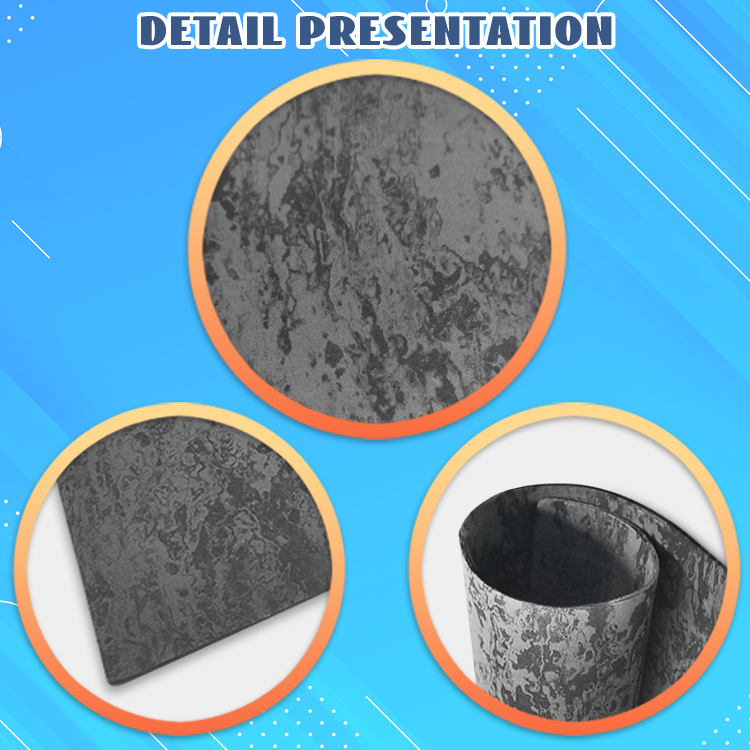

1. Know about EVA Sheets

EVA sheets are basically prepared from a copolymer of the following: ethylene and vinyl acetate. This gives them a unique property mixture of flexibility, lightweight nature, impact resistance, and moisture resistance. They thus find broad uses in cushioning and insulation, protective coverings, and sealants.

2. Choosing the Correct EVA Sheet

Choosing the right EVA sheet will ensure conformance to your industrial needs. The considerations should be based on the following:

- Thickness and Density: EVA sheets are available in various thicknesses and densities. Thicker ones provide more cushioning and insulation; on the other hand, thinner ones are more flexible.

- Color and Finish: Depending upon the application, you may want to call for a specific color or finish. For example, anti-slip finishes can be great on flooring applications, and even smooth surfaces work on protective covers.

- Temperature and Chemical Resistance: Confirm that the EVA sheet will be compatible with the environmental conditions to which it is going to be exposed, relating to temperature extremes and exposure to chemicals.

3. Cutting and Shaping EVA Sheets

Correct cutting and shaping are important in bringing out the desired outcome. Here are some best practices:

- Use the Right Tools: Cut precisely with sharp utility knives or band saws. Keep your tools in good condition to avoid lopsided edges.

- Measure Twice, Cut Once: Measure the dimensions of the foam first. Mark your cuts with a ruler and marker before making the cut.

- Avoid Overheating: EVA sheets can get tacky or melt when exposed to excessive heat. Work in a well-ventilated area and take measures to prevent overheating while cutting.

4. Installation and Adhesion

For EVA sheets, adhesion is of essence for its durability and efficiency in the installation process. The surfaces that the EVA sheets will be attached to must be cleaned of dust, oil, or other elements. The other process in adhesion is the choice of adhesive; this calls for the application of adhesive materials which are compatible with EVA; Contact cement or industrial grade double-sided tape applies to general industrial applications.

- Application Techniques: Apply the adhesive uniformly, and press the EVA sheet firmly on the surface. Rollers or squeegees may be used to squeeze out air bubbles and enforce full contact.

5. Maintenance and Care

To have EVA sheets last as long as possible, periodic maintenance is required:

- Cleaning: EVA sheets should be cleaned using mild detergents and water. One must avoid strong chemicals, which may have a deteriorating effect on the material.

- Inspection: Regularly inspect the sheets for any signs of wear or damage. Attend to the points of issue immediately to help prevent further deterioration.

- Storage: Store EVA sheets in a cold, dry place, away from direct sunlight or extreme temperatures, which may impart brittleness or discoloration.

6. Troubleshooting Common Issues

Even with good handling, things can go wrong. Here’s how to resolve some common problems:

- Peeling Edges: If the edges start peeling, probably it could be due to insufficient adhesive or poor surface preparation. Renounce with adhesive and clean properly before re-installation.

- Bumps/ Bubbles on the Surface: Should the EVA sheet come up with bumps or bubbles, probably it could be as a result of air trapped in the course of installation. Carefully cut and reseal the damaged area.

- Discoloration: With time, the EVA sheets discolor. While in general this does not affect the performance of the device under question, protective coatings will minimize aesthetic changes.

FAQ

Q: Can EVA sheets be used outdoors?

A: Yes, EVA sheets can be used outdoors, provided that they have undergone UV resistance treatment and are suited for the particular kind of environmental elements they will face.

Q: How do I dispose of EVA sheets?

A: EVA sheets must be disposed of in accordance with local regulations governing such materials. Most recycling centers accept EVA materials, but always check with the waste management facilities in your area.

Q: Can EVA sheets be used in high-temperature applications?

A: EVA sheets, generally speaking, might not withstand very high temperatures. Only especially engineered materials for their resistance to such thermal situations are to be recommended to this kind of application.