The hardness of EVA (ethylene-vinyl acetate) can be formulated to a certain extent. EVA is a versatile material that can be adjusted in terms of its hardness or durometer. A durometer is a measure of the material’s resistance to indentation or hardness.

The hardness of EVA is typically measured on the Shore A or Shore D scale. The Shore A scale is used for softer materials, while the Shore D scale is used for harder materials. EVA can range in hardness from very soft (around 20 Shore A) to relatively hard (up to 90 Shore A or higher).

The hardness of EVA can be adjusted during the manufacturing process by altering the ratio of ethylene and vinyl acetate in the polymer blend. Increasing the vinyl acetate content generally results in a softer EVA, while decreasing it leads to a harder EVA.

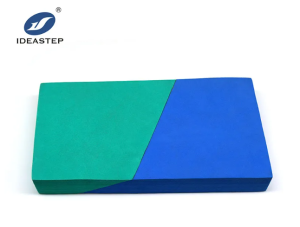

By formulating EVA with different hardness levels, manufacturers can create insoles with varying degrees of cushioning, support, and shock absorption. Softer EVA insoles may provide more cushioning and comfort, while harder EVA insoles may offer greater stability and durability.

It’s important to note that the specific hardness range and formulation of EVA can vary among manufacturers and their proprietary formulations. Additionally, other factors such as the thickness and design of the insole can also influence the overall feel and performance.

More materials can be found here: https://www.eva-block.com/products/.