Electronics Packaging

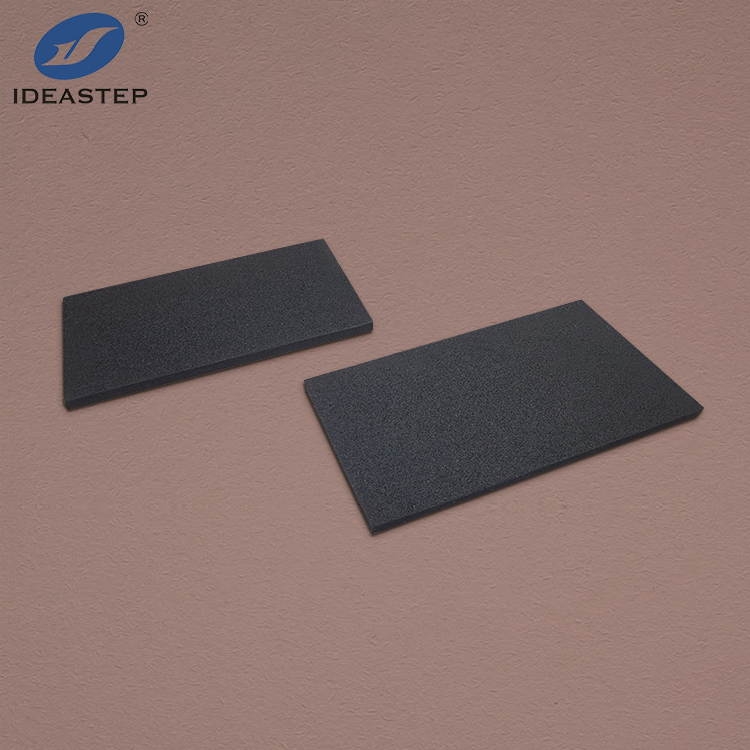

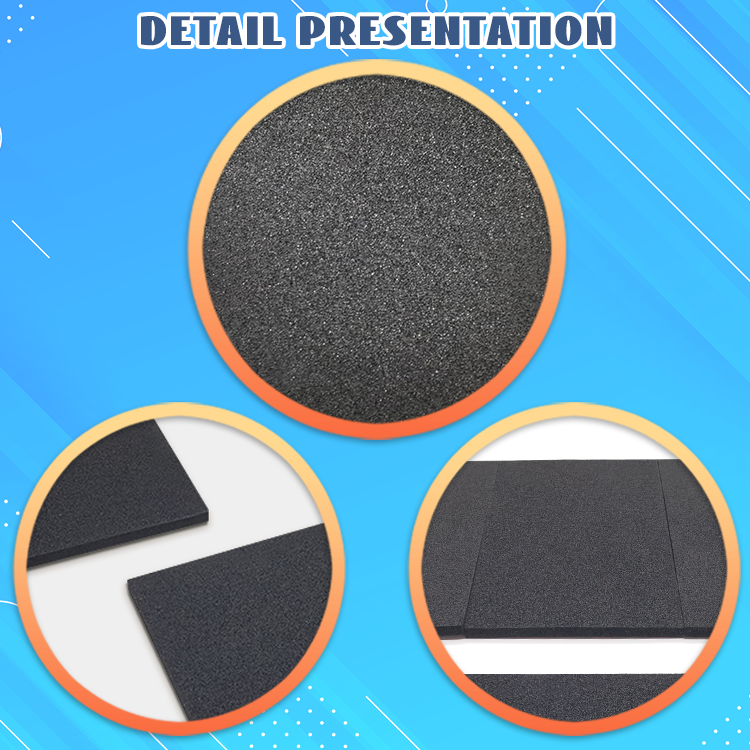

One of the primary applications of anti-static EVA foam sheets is in the packaging of electronic components and devices. These foam sheets provide protection against electrostatic discharge (ESD), which can damage sensitive electronic circuits. Ideastep ensures their anti-static EVA foam sheets meet industry standards for ESD protection, safeguarding electronic products during storage and transportation.

Cleanroom Environments

Anti-static EVA foam sheets are also used in cleanroom environments where maintaining a controlled level of static electricity is crucial. Industries such as semiconductor manufacturing, pharmaceuticals, and biotechnology rely on these foam sheets to prevent static buildup that could compromise product quality or safety. The anti-static properties of these foam sheets contribute to maintaining cleanroom standards and reducing contamination risks.

Industrial Applications

Beyond electronics and cleanrooms, anti-static EVA foam sheets are employed in various industrial applications where static electricity poses a risk to sensitive equipment or materials. These include automotive manufacturing, aerospace, and medical equipment production. Their versatility and effectiveness in mitigating ESD make them indispensable in ensuring operational reliability and product integrity.

Conclusion

In conclusion, anti-static EVA foam sheets play a critical role in industries requiring protection against electrostatic discharge. Their applications span across electronics packaging, cleanroom environments, and various industrial settings where maintaining a static-free environment is essential. By understanding their applications, businesses can leverage these foam sheets to enhance product protection, safety, and operational efficiency.