Synopsis: Working with thick colorful rubber EVA sheets presents exceptional challenges that can impact project outcomes. This article explores common issues experienced when handling these materials and offers practical solutions to overcome them, ensuring optimal performance and quality in custom applications.

Introduction to Challenges with Thick Colorful Rubber EVA Sheets

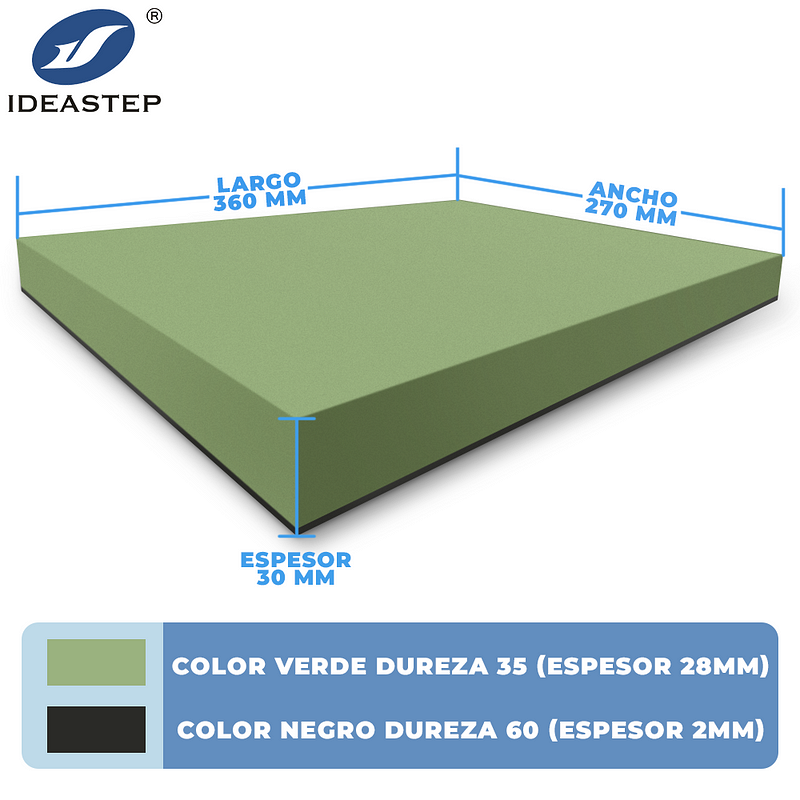

Thick colorful rubber EVA (Ethylene Vinyl Acetate) sheets are versatile materials used in various applications, from industrial components to artistic projects. While their flexibility and durability are beneficial, working with these sheets can present several challenges. Understanding these challenges and how to address them is crucial for achieving success in your projects.

Common Challenges and Solutions

1. Cutting Difficulties

Challenge: Cutting thick EVA sheets accurately can be challenging due to their density and thickness. Inaccurate cuts can lead to wasted material and project delays.

Solution: Use the appropriate cutting tools for the job. For straight cuts, a sharp utility knife or a rotary cutter is effective. For intricate or curved cuts, consider using a jigsaw with a fine-toothed blade. Ensure that your cutting tools are well-maintained and sharp to achieve clean, precise cuts. Using a cutting mat can also help protect surfaces and improve accuracy.

2. Color Variability

Challenge: Color consistency can be an issue, especially when working with sheets from different batches. Variations in color can affect the appearance and uniformity of the final product.

Solution: To maintain color consistency, source all your EVA sheets from the same batch or supplier. If working with sheets from different batches, perform a test to check for color variations before starting your project. Additionally, be aware of how lighting conditions and camera settings can affect the perception of color.

3. Heat Sensitivity

Challenge: EVA foam can be sensitive to heat, which may cause it to deform or lose its properties if not handled correctly. This can be particularly problematic when shaping or bonding the material.

Solution: When using heat to shape EVA sheets, apply it gradually and evenly to avoid overheating. Use a heat gun or an oven with precise temperature controls to ensure consistent heating. Monitor the material closely and test it periodically to prevent overheating. Additionally, always work in a well-ventilated area to manage any fumes released during heating.

4. Adhesive Challenges

Challenge: Selecting the right adhesive for bonding EVA sheets can be difficult. Incompatible adhesives can lead to weak bonds or damage to the material.

Solution: Choose adhesives specifically designed for use with EVA foam. Spray adhesives or EVA-specific contact adhesives are typically effective. Test the adhesive on a small piece of scrap material first to ensure compatibility and bond strength. Follow the manufacturer’s instructions for application and curing times.

5. Edge Finishing

Challenge: Thick EVA sheets can have rough or uneven edges after cutting, which can affect the overall appearance and functionality of the final product.

Solution: After cutting, smooth the edges using fine-grit sandpaper or a file. This will help eliminate any rough spots and provide a professional finish. For colorful EVA sheets, be careful not to damage the surface while finishing the edges. A gentle touch and consistent sanding will ensure a clean, smooth edge.

6. Storage and Handling

Challenge: Improper storage and handling of EVA sheets can lead to deformation, dust accumulation, or damage.

Solution: Store EVA sheets in a cool, dry place away from direct sunlight and extreme temperatures. Use protective covers or sheets to prevent dust accumulation. When handling, avoid sharp objects and excessive force that could cause physical damage to the material. Proper storage and careful handling will extend the life and maintain the quality of your EVA sheets.

Best Practices for Success

To achieve the best results when working with thick colorful rubber EVA sheets, follow these best practices:

- Regularly Maintain Tools: Keep cutting tools sharp and in good condition to ensure precise cuts and reduce the risk of errors.

- Perform Quality Checks: Regularly inspect the sheets and finished products for defects or inconsistencies.

- Stay Informed: Keep up to date with new techniques and tools for working with EVA foam to continuously improve your skills and outcomes.

Conclusion

Understanding and addressing the common challenges associated with thick colorful rubber EVA sheets can significantly enhance the quality and efficiency of your projects. By employing the right tools, techniques, and best practices, you can overcome these obstacles and achieve optimal results. For high-quality EVA sheets and expert advice, consider working with trusted suppliers like Ideastep.

FAQ

Q1: What tools are recommended for cutting thick EVA sheets?

A1: Sharp utility knives, rotary cutters, and electric cutting machines are recommended for cutting thick EVA sheets. The choice of tool depends on the complexity and size of the cut required.

Q2: How can I ensure color consistency when using EVA sheets?

A2: To ensure color consistency, source sheets from the same batch or supplier and perform color checks before starting your project. Consider the impact of lighting on color perception.

Q3: What should I do if EVA sheets deform due to heat?

A3: Apply heat gradually and monitor the material closely to prevent overheating. Use a heat gun or oven with precise temperature controls and work in a well-ventilated area.