Introduction

From the selection point of view, EVA rubber sheets can provide a rather wide range of variability for your projects. Being in a position to make informed decisions which may considerably affect durability, comfort, and cost requires some understanding of the types of EVA rubber sheets. This guide takes a look into the types of EVA rubber sheets, their fields of application, and some key considerations that will lead you to the best choice for your needs.

1. What Are EVA Rubber Sheets?

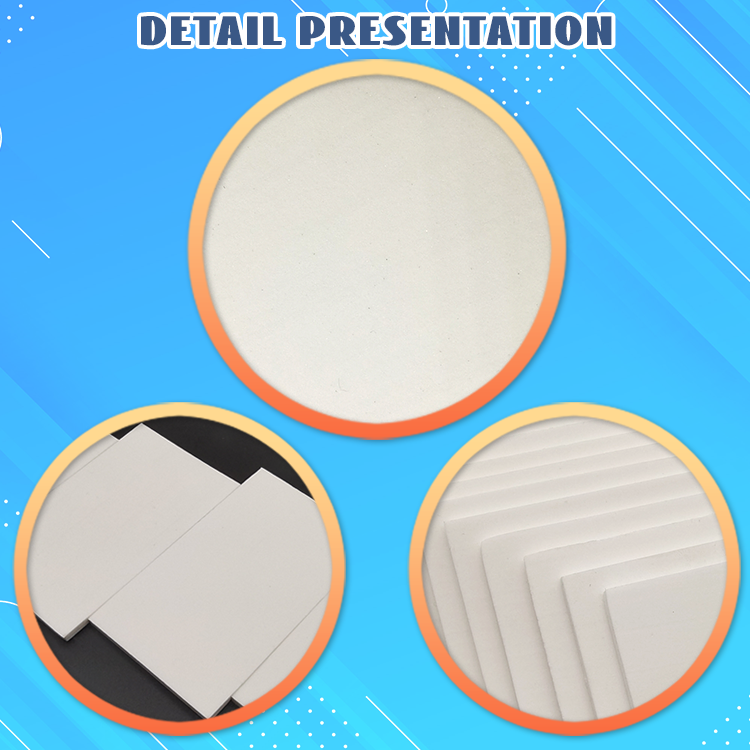

EVA rubber sheets are made from Ethylene Vinyl Acetate, a copolymer that exhibits both flexibility and toughness. Indeed, owing to their facilitation in cushioning, providing insulation, and withstanding impacts, these sheets find applications across many industries. Some of the important properties include being lightweight, water- and chemical-resistant, and printable or paintable upon demand.

2. Types of EVA Rubber Sheets

Standard EVA Rubber Sheets

The most common variety of EVA rubber sheets is the standard, which strikes a fine balance between flexibility and durability. They can be used on a wide range of applications, from footwear insoles to protective mats.

High-Density EVA Rubber Sheets

High-density EVA rubber sheets exhibit greater strength and durability compared to the standard ones. They are ideal for industrial applications where resistance to impact and durability is highly required.

Foam EVA Rubber Sheets

The cushioned EVA rubber sheets have a spongy texture. For this reason, they find application in areas where shock absorption is necessary: sports equipment, padding lotions, among others.

Coloured EVA Rubber Sheets

Coloured EVA rubber sheets are of different colours. This could be for design and branding purposes. Commonly used in consumer products and promotional items where outlook is very important.

3. How Different Types of EVA Rubber Sheets Vary

Durability and Strength

Various EVA rubber sheets differ in such aspects as durability and strength. High-density sheets offer better resistance to impacts compared to the standard ones, hence being appropriate for use in demanding environments.

Flexibility and Comfort

The foam EVA rubber sheets are excellent in flexibility and comfort, hence providing very effective cushioning. The standard sheets offer average flexibility, whereas high-density options may not be that flexible but will be stronger.

Cost and Budget Considerations

The prices of EVA rubber sheets vary according to their type. The standard sheets are not very costly, but the high-density sheets and sheets of custom color are pretty expensive. It is going to be a balance between budget and requirements of an application.

Environmental Impact

EVA rubber sheets can be recycled for the most part, but the environmental impact will differ. High-density and custom-colored sheets could have a different sustainability profile than the standard options.

4. Applications and Best Use Cases

Industrial Uses

High-density EVA rubber sheets are used in industry because of their resistance and toughness. Applications cover machinery padding, protective mats, and impact-resistant barriers.

Consumer Products

In consumer products, comfort and resilience make EVA sheets preferred for use in certain products such as footwear and sporting goods. Of the many types of EVA sheets, the foam ones are particularly in demand because they provide extra cushion.

Custom Applications

EVA rubber sheets can be customized for particular needs, such as shapes or color requirements. This is why they are so versatile and mostly used in value-added projects and customized solutions.

5. How to Choose the Correct EVA Rubber Sheet

Assess Your Requirements

Choose the basic requirements for an application, durability, flexibility, and comfort. Match these requirements with the type of EVA rubber sheet needed.

Ask the Experts

Consulting professionals will help you understand how to go about choosing an EVA rubber sheet that best suits your needs. It gives you insight from the expert’s point of view, enabling you to avoid common mistakes and get good performance.

Testing and Samples

Look at samples and make a choice. You will only be able to decide which option is best for you by testing various types of EVA rubber sheets.

6. Solutions to Common Problems

How to Choose the Right Type

A wrong selection of the EVA rubber sheets may not perform exactly as desired. Understand the properties of each type of EVA rubber and their appropriateness for your project requirements.

Handling and Maintenance

The proper handling and maintenance of EVA rubber sheets contribute to their long life. Follow the guidelines given by the manufacturer for its care and storage.

Performance Issues

If problems continue to appear, check material type, application environment, and maintenance practices. Some common problems can be treated with specific remedies to achieve suitable outcomes.

7. Frequently Asked Questions

What are the differences between regular and high-density EVA rubber sheets?

Regular EVA sheets will give a good balance between durability and flexibility, whereas high-density sheets can exhibit higher strength and resistance to impacts.

Can EVA rubber sheets be used outdoors?

Yes, but the suitability depends on the type of EVA sheet and the surrounding environmental conditions. Ensure the selected sheet is designed for outdoor use, if that is going to be a requirement.

How does colored EVA rubber sheet affect price and functionality?

Colored EVA sheets might be more costly because of customization, but they have aesthetic benefits in branding and design.

Are EVA rubber sheets eco-friendly and recyclable?

Most EVA rubber sheets are technically recyclable, although many have different environmental impacts. Please consider the sustainability profile of the particular product in question.

Selection Criteria for EVA Rubber Sheets

What do I need to take into consideration when choosing EVA rubber sheets to suit my application? Material properties, customization options, and application needs—the things you may want to take into consideration. Consult the experts for better advice.

Customer Experience Share

I have already been using EVA rubber sheets in various projects. This is not only because of their versatility but also because of their performance capabilities. Later on, I was working on an industrial project that needed high-density EVA sheets. The durability was not just top-notch, but the impact resistance also remained great, making the product entirely apt for the particular need. Advantageous ability for color customizations to do branding came pretty handy too. With time, the EVA sheets have proved reliable for both industrial and consumer applications.