The properties of EVA foam, ranging from versatility to adaptability, extend to a broad span of applications that it finds itself serving—from sports equipment to car parts. Performance for these different conditions depends on temperature resistance and durability. Understanding these properties is important in the choice of right EVA products to meet the needs at hand effectively. This article focuses on the temperatures and durability resistance involving applications of EVA and how such factors could make much impact on product performance and longevity.

1. Understanding EVA Foam and Its Properties

What is EVA Foam?

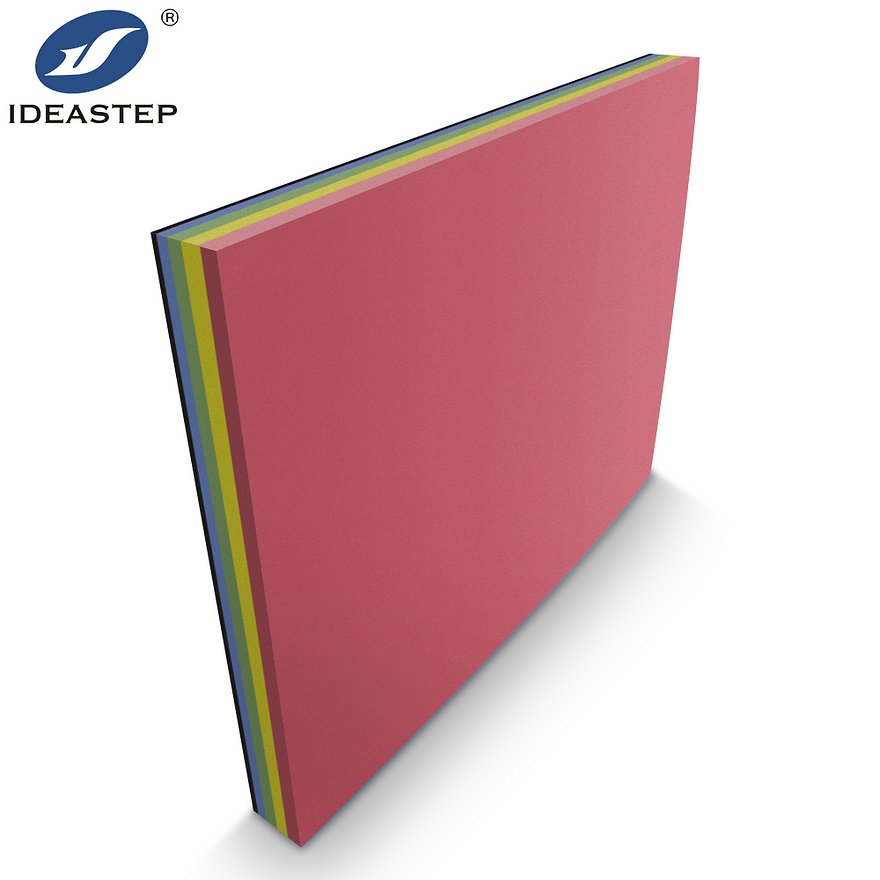

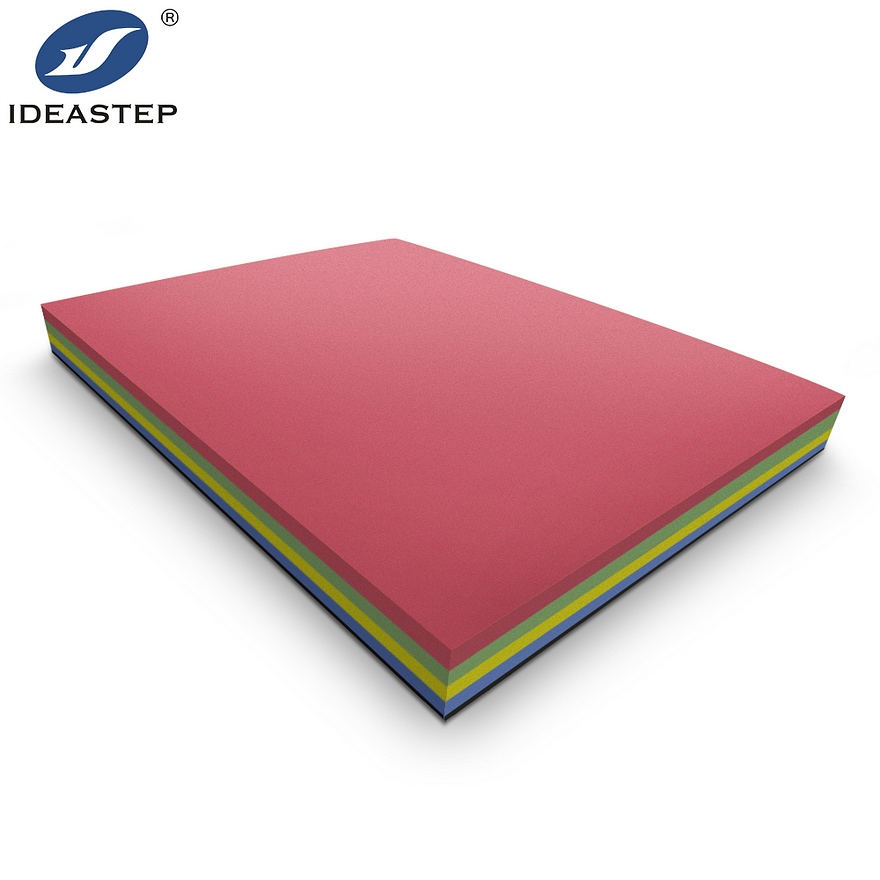

EVA foam is a cellular material with the properties of flexibility, cushioning, and absorbing shock. Composed of ethylene and vinyl acetate, it is good in impact resistance and comfort, hence a host for many kinds of uses.

Temperature Resistance in EVA Foam

EVA foam can bear high and low temperatures, but the actual usability depends upon the temperature range. For example, high temperatures would most probably soften the foam or result in its deformation, while low temperatures will definitely impact its flex and rigidity. It becomes important to understand how EVA foam behaves at different temperatures to make informed decisions on uses where this material will encounter extreme fluctuation.

2. Importance of Temperature Resistance in EVA Applications

Applications Requiring High Temperature Resistance

In the automotive parts, industrial seals, and also protective gear, high resistance to temperature is paramount. EVA foams utilized for these purposes will be required to retain their structural integrity and performance even at high heat, with the importance of safety and functionality in mind.

Applications Requiring Low Temperature Resistance

On the other hand, various products in sports equipment and cold-weather gears utilize EVA foam in applications requiring resistance to low temperatures. These applications require EVA foam to be flexible and operable under freezing conditions to ensure better comfort and performance for its users.

3. EVA Foam Durability: Important Factors to Consider

Factors Affecting Durability

The factors influencing EVA foam durability are UV exposure, moisture, and mechanical stress. High-quality raw materials and processes in manufacturing equally have a very major influence on the life of the foam.

Advantages of Durable EVA Foam

Durable EVA foam confers several long-term cost and reliability advantages as it negates the process of constant replacement of the material. It has better performance of products made of it and their safety, especially in harsh environments that are conducive to wear and tear.

4. Temperature Resistance and Durability of EVA Foam Products

Choosing the Best Type of Foam for the Job

The methods through which EVA foam is selected are dependent on temperature resistance, density, thickness, and formulation. This will ensure that the foam has continued performance in your particular application for whatever the high temperature or low temperature that the job entails.

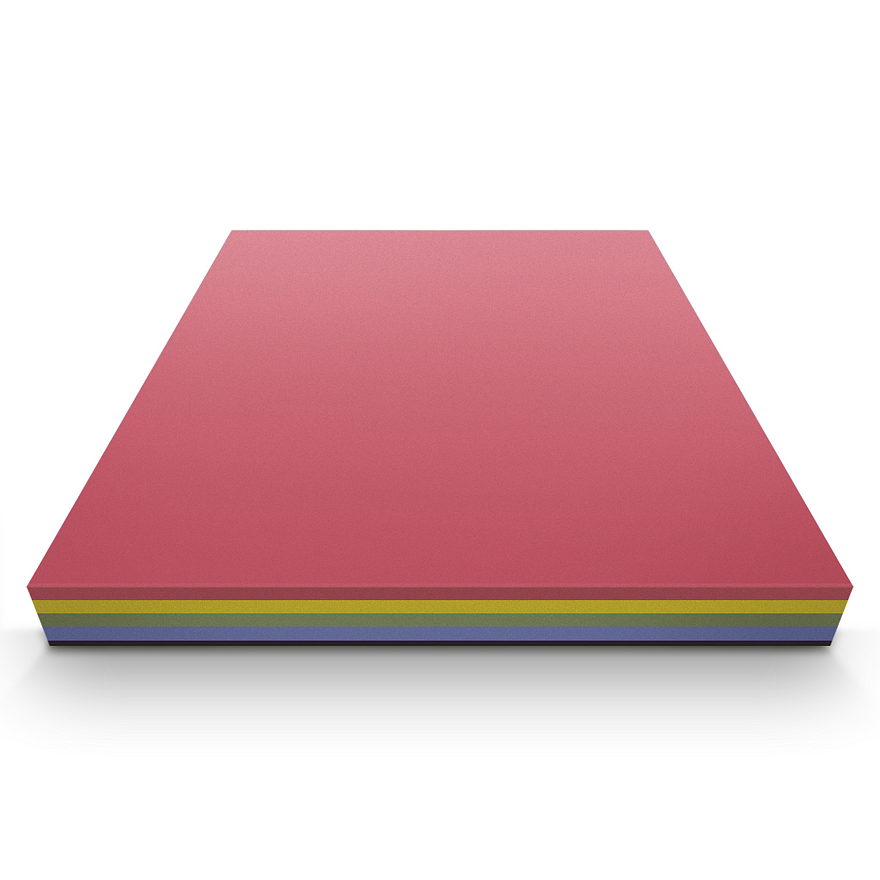

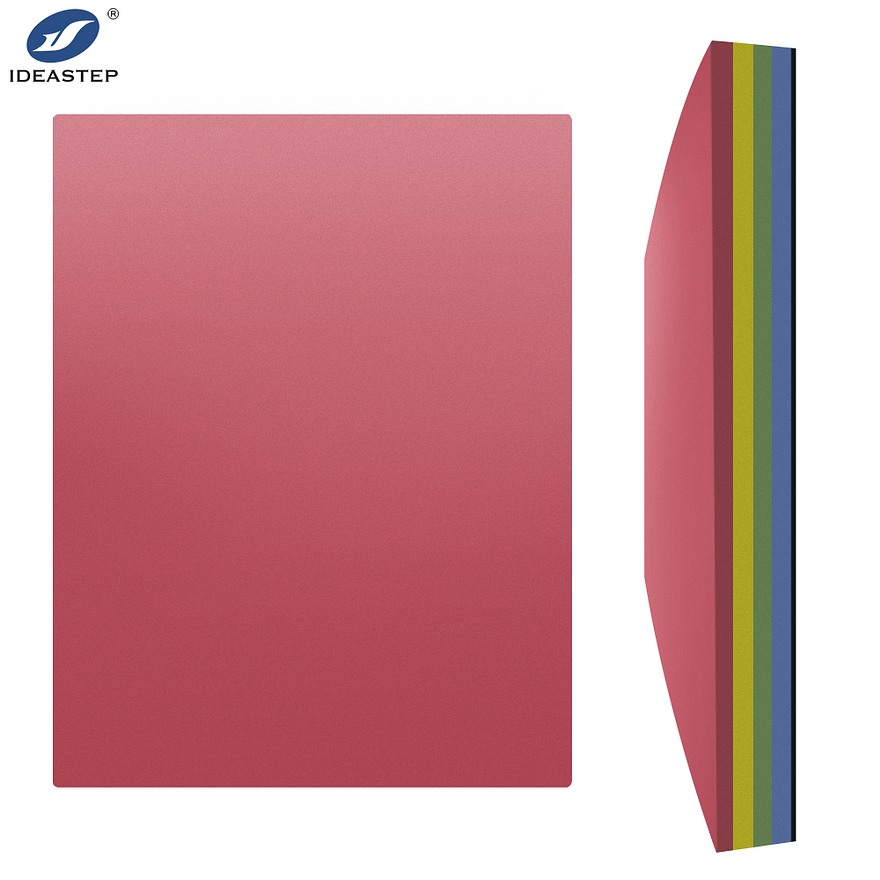

Examples of High-Quality EVA Foam Products

Suppliers like Ideastep provide EVA foam products custom-fitted to desired specifications for temperature resistance and durability. Being able to explore these products will go a long way to find the best fit for your needs.

5. Personal Experience: Using EVA Products

My Experience with EVA Foam

Having tried several EVA products myself, I notice how the proper selection of foam, considering appropriate temperature resistance and durability, has major implications in terms of performance and the product life cycle. For example, highly dense EVA foam provides great protection and durability for industrial applications while providing comfort in sports equipment.

Recommendations

You can choose EVA products based on your needs to enhance temperature and durability. Working with great manufacturers, like Ideastep, you will definitely get good quality and tailored-to-your-need items.

6. FAQs

What is the relevance of temperature resistance in EVA foam applications?

The temperature resistance of EVA will usually guarantee good quality and durability over time in the most critical situations for EVA foam products.

How does the durability of EVA foam affect its applications?

Since durability guarantees that over time, EVA foam will be performing reliably, then there is superior protection and fewer replacements.

Factors to consider when selecting the appropriate EVA foam for an application:

Temperature resistance, density, thickness, and formulation are key factors when it comes to picking EVA foam for whatever application it’s supposed to serve.

Does EVA foam hold its properties in extreme temperatures?

EVA foams work differently at extreme temperatures. A high-quality EVA foam is built in such a way that its properties can be maintained in extremely fluctuated conditions.

If you are interested in EVA , you can continue to visit this page (https://www.eva-block.com/product/) and tell us your needs.