EVA foam customization is one of those transformational processes whereby the performance, durability, and functionality of the products are enhanced for applications that involve almost all industries. Understanding key techniques and their benefits helps make appropriate decisions for the best results in your specific needs. This article will delve into the critical techniques incorporated in EVA foam customization and demonstrate how each will be able to ensure product performance is optimized.

1. Understanding EVA Foam Customization

What is EVA Foam Customization?

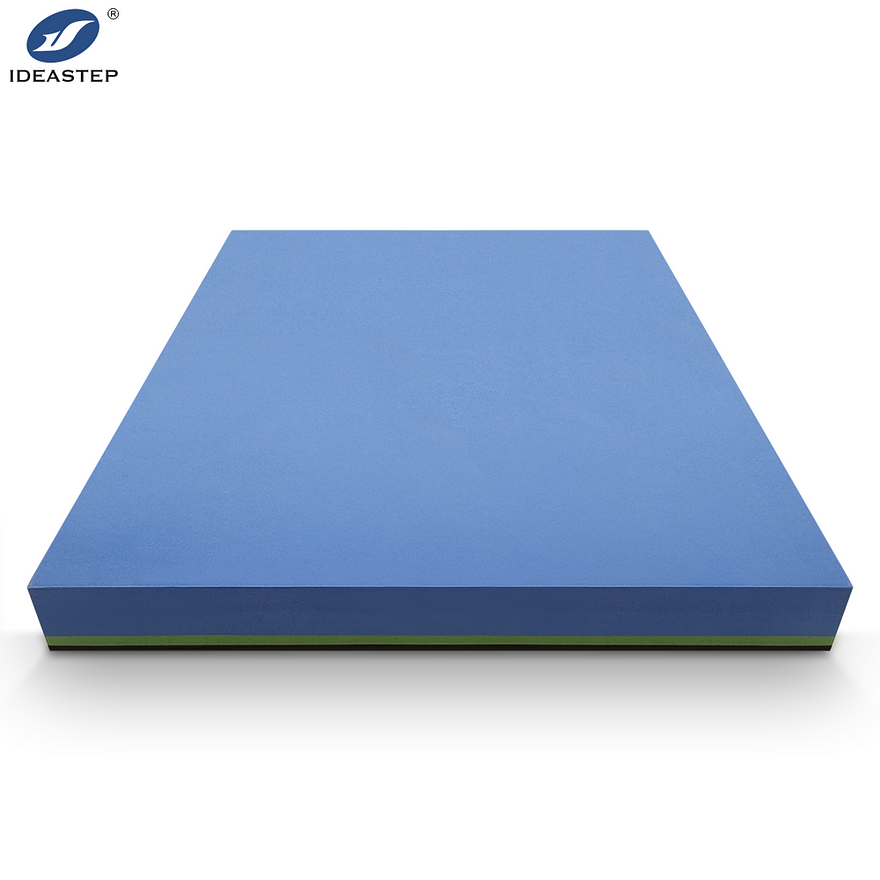

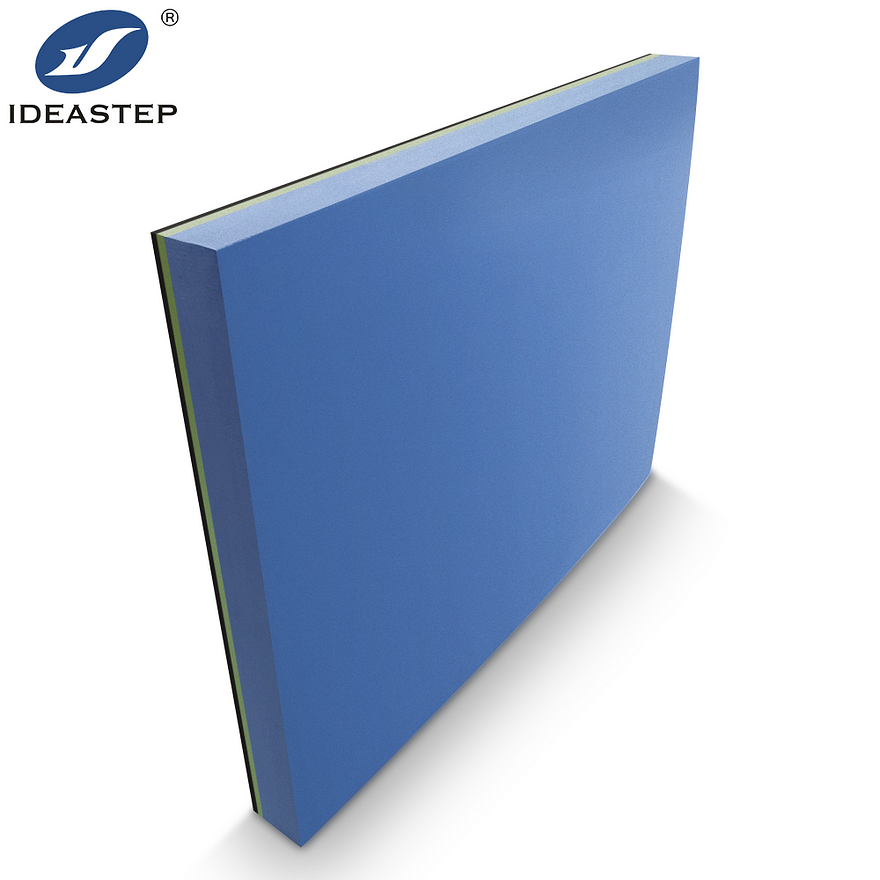

EVA foam customization is the work of changing properties in EVA foam to fit specific needs. It includes changes in density, thickness, and shape, which would allow it to have improved performance for use in everything from sports equipment to industrial products.

Benefits of Customizing EVA Foam

Performance also tends to be better with customized EVA foam because the properties can be accommodated to best suit intended use. The product will, therefore, be enhanced in both durability and functionality. This means it works more effectively and has a longer life.

2. Key Manufacturing Techniques for EVA Foam Customization

Injection Molding

It involves melting EVA foam and injecting it into a mold to get an accurate shape. It will offer a very high level of accuracy, repeatability, and is ideal for complex designs with high volume.

Compression Molding

In compression molding, EVA foam is placed inside a hot mold and subjected to pressure. Compression molding is considered an economical method for production in larger runs and is capable of manufacturing simple to moderately complex shapes.

Blow Molding

Blow molding is performed by inflating a heated EVA foam tube into a mold. Such a technique allows for the realization of hollow, lightweight items with several shapes, thus responding to all those applications requiring weight optimization.

Thermoforming

EVA foam may be thermoformed through softening with heat, after which it is molded into the desired shape. It’s quick and can be adapted for custom shapes and sizes, making this process very appropriate for small to medium runs of production.

Cutting and Shaping Techniques

Different cutting techniques include die cutting and laser cutting, by which foam of specific thickness and density can be tailored with high accuracy. These techniques are flexible and lend themselves to the creation of pieces of foam in custom shapes in such a manner as to fit special applications.

3. Choosing the Correct Method for Your Application

Factors to Consider

Each of these methods has its particular strengths that make it more or less suited to various types of applications. In choosing a manufacturing technique, attention has to be paid not only to the scale of production and budget but also to the specific properties desired in the foam—for example, density and flexibility.

Techniques Compared

Further, evaluate how any one method might meet your requirements based on factors such as cost, the volume of production, and the level of shape complication of the foams. This will help you in determining the most feasible method of application for your project.

4. Personal Experience: Using Custom EVA Foam Products

My Experience with EVA Foam Customization

Having dealt with several custom EVA foam products, the advantages of choosing the right technique were considerable: for example, high-density EVA foams protect great gear by increasing safety and durability, while low-density foams can be used comfortably in less demanding applications. Ideastep’s capability in customization has been an invaluable experience toward the achievement of desired performance with the products and increasing their life span.

Recommendations for Optimal Customization

It is, therefore, recommended, for the best results, choosing the most suitable method to suit one’s needs and engaging the services of manufacturers like Ideastep that have customization tailored for a client’s specific need and requirement with the highest quality the process demands.

5. FAQs

What are the major benefits of EVA foam customization?

The customized EVA foam has better performance, durability, and functionality of the materials in best serving them to specified uses.

How to Choose the Manufacturing Technique for My Needs?

While choosing a technique, consider the desired properties of the foam, the volume of production, and the budget.

Can Customized EVA Foam Be Used for Industrial and Consumer Products?

Yes, EVA customization can fit into almost every field—starting from industrial applications to consumer products.

What Are the Things That One Should Look for in an Appropriate EVA Foam Reliable Manufacturer?

Look for manufacturers with experience in customization, capability proven, and with strict quality control in place.

Are there any limitations on how one can customize EVA foam?

Potential limitations may come from higher costs for certain techniques of customization to keep the overall budget within capability.

If you are interested in EVA , you can continue to visit this page (https://www.eva-block.com/product/) and tell us your needs.