Introduction

Overview of EVA Material

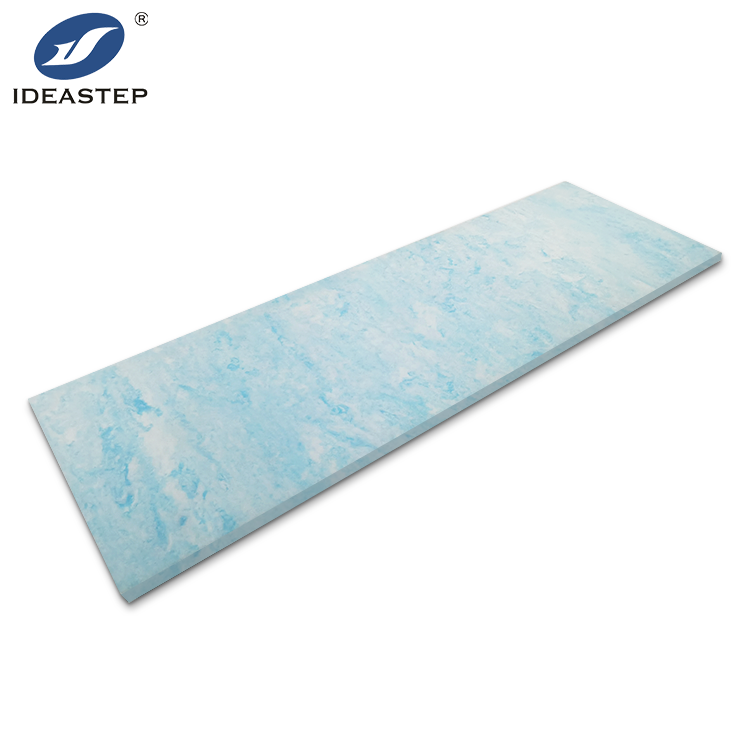

One of the most used materials is ethylene vinyl acetate (EVA) due to its characteristic features. The EVA material consists of ethylene and vinyl acetate and therefore contains the combining features of flexibility, cushioning, and toughness. The products ranging from shoes and sporting gear to packaging, construction, and many others have incorporated this material.

Importance of Integration

Integrating EVA material into your production systems can significantly improve the performance of any product and further bring cost efficiency. This article will show you how to easily integrate EVA into your production processes and get optimal results.

1. Understanding EVA Material

What is EVA Material?

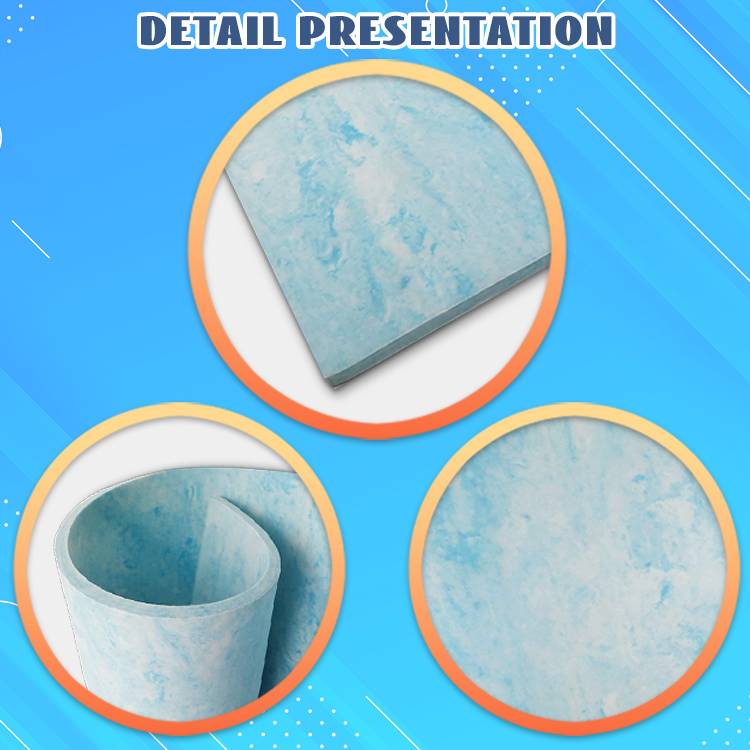

EVA material is a polymer blend of ethylene and vinyl acetate. The material is lightweight and elastic. It has a high degree of shock and stress resistance, making it suitable for many applications.

Key Properties of EVA

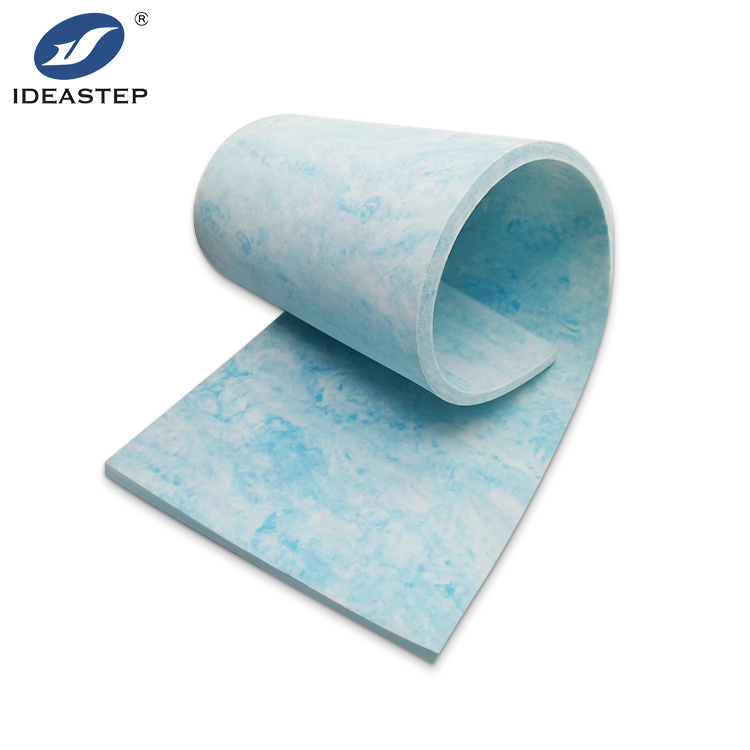

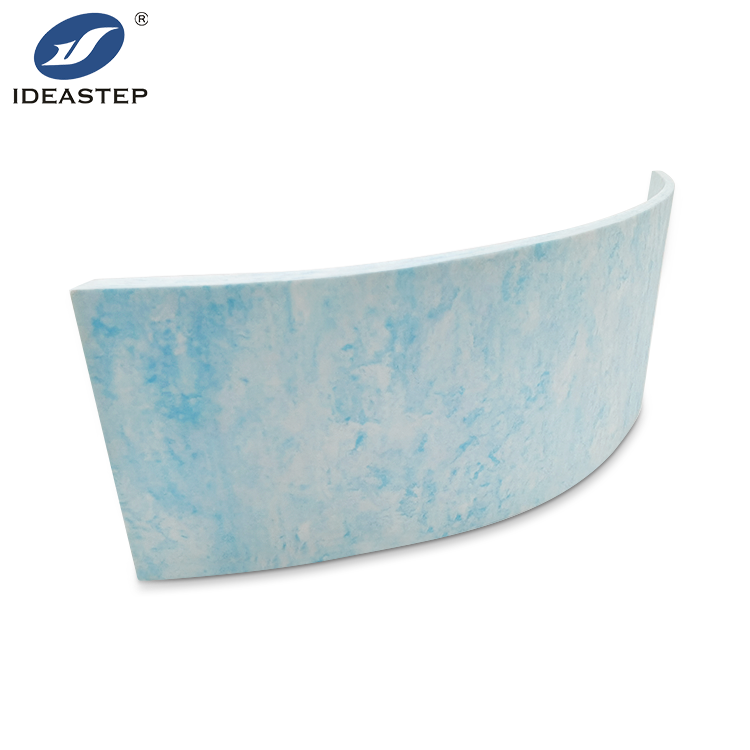

Basically, EVA material is soft and resilient. Its flexibility allows it to conform to various shapes, making it suitable for different applications, while its shock-absorbing capabilities enhance product durability.

2. Merits of Using EVA Material

Enhanced Product Performance

EVA material can significantly enhance product performance. Its cushioning effect provides better comfort and impact reduction, making it ideal for insoles and padding.

Economical

The material can lead to economic production. Since EVA is durable, it doesn’t need frequent replacements. It can also serve multiple purposes, reducing the need to stock various materials.

Versatility

EVA material is highly versatile and can be applied in production, construction, and consumer goods industries. This versatility highlights its effectiveness across different applications.

3. Integrating EVA Material into Production Systems

Evaluating Your Production Needs

First, evaluate your production needs before integrating EVA material. Define how EVA will enhance your system by considering its properties, your production goals, and specific application requirements.

How to Choose the Right EVA Material

Different types of EVA material are available for various applications. Selection criteria such as density, thickness, and flexibility are crucial in determining which EVA material best suits your system’s functionality.

Design Considerations

Designing your production system to incorporate EVA material involves understanding its properties. Design accordingly to leverage its flexibility and cushioning capabilities.

Implementation Strategies

To integrate EVA material effectively, follow these steps:

- Planning: Develop a plan for integrating EVA material into your system.

- Trial: Conduct trials to test the material’s compatibility with your production system.

- Correction: Make necessary adjustments based on trial results to optimize the integration process.

4. Case Studies and Examples

Manufacturing Industry

Introducing EVA material into a manufacturer’s production line improved product cushioning and reduced waste, resulting in a 15% increase in efficiency.

Construction Industry

In construction, EVA material used for insulation and padding enhanced safety and energy efficiency, reducing material costs by 20%.

Consumer Goods

Consumer goods companies have utilized EVA material in products like shoes and sporting gear, improving comfort and durability.

5. Common Issues and Their Solutions

Processing and Storage Problems

EVA material requires proper handling and storage. Store it in a cool, dry area and handle it gently to avoid deterioration.

Compatibility with Existing Systems

Compatibility issues may arise when integrating EVA material. Ensure that your production equipment and processes are compatible or make necessary adjustments.

Cost Control

While EVA material offers cost benefits, integration costs can be a concern. Manage costs by optimizing material use and exploring cost-effective sourcing options.

6. Conclusion

Summary of Key Takeaways

Using EVA material in manufacturing systems provides numerous benefits, including enhanced product performance, increased cost efficiency, and versatility. Following best practices and addressing common challenges will help you achieve optimal results.

Conclusion

Incorporate EVA material into your production process to harness its benefits and improve overall efficiency. Leverage EVA for better product reinforcement and streamlined operations.

Frequently Asked Questions

What are the core benefits of EVA material to a production system?

EVA material enhances product performance by providing cushioning and shock protection. It is also economical and flexible for various applications.

Where to obtain the right type of EVA material for my use?

Choose EVA material based on your density, thickness, and flexibility requirements to match your production needs.

What are some of the general challenges in the incorporation of EVA material and how are they solved?

Common challenges include handling and storage issues, compatibility with existing systems, and cost management. Address these through proper planning, testing, and optimization.

Is the EVA material eco-friendly?

EVA material can be recycled or reused, and many industries have recycling programs, making it an eco-friendly option for various applications.