EVA sheets have widely been employed in industries due to their versatile and durable nature, extended to anti-slip applications. From enhancing workplace or industry safety to dependable traction delivered to consumer products, anti-slip features of EVA sheets are highly instrumental. The article describes the entire manufacturing process of EVA sheets with anti-slip properties, right from the selection of raw materials to the final product itself, and discusses the reasons these properties are so important in a wide variety of applications.

1. Raw Materials for EVA Sheets

1.1 Understanding EVA Foam Composition

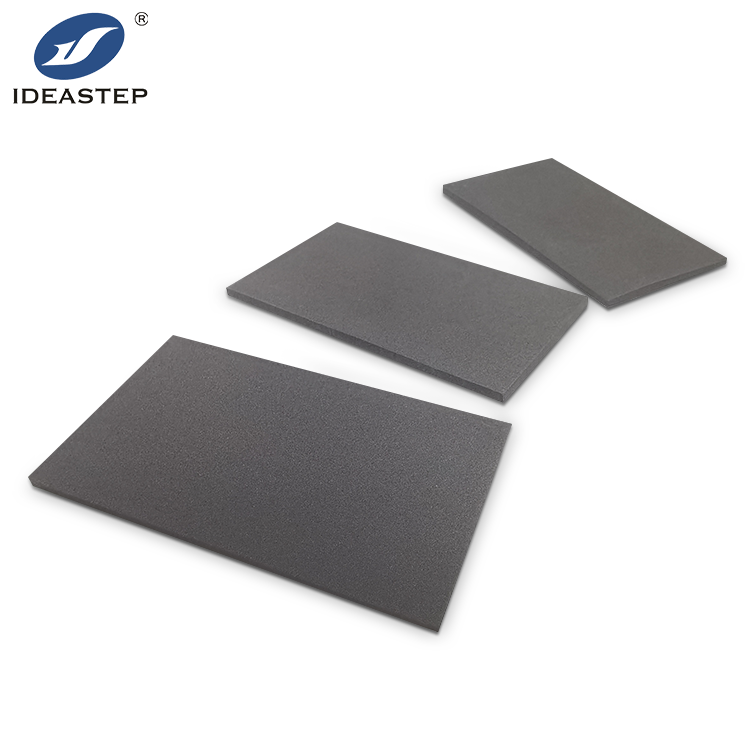

EVA foam, or ethylene-vinyl acetate foam, is a somewhat elastic, shock-absorbing material. The durability of EVA foam sheets totally depends on the quality of the material itself, such as anti-slip ones.

1.2 Selection of Raw Materials

Selection of good quality EVA raw materials would mean the effectiveness of the anti-slip feature. The proper quality control at the entry of materials is in place to ensure the conformance of materials to the required standard for performance and safety.

2. The Manufacturing Process

2.1 Initial Processing: Compounding and Mixing

The process of manufacture begins with the compounding of EVA resin with anti-slip additives, a process in need of special equipment to produce a consistent mixture that is important in the continually effective performance of anti-slip.

2.2 Shaping and Forming EVA Sheets

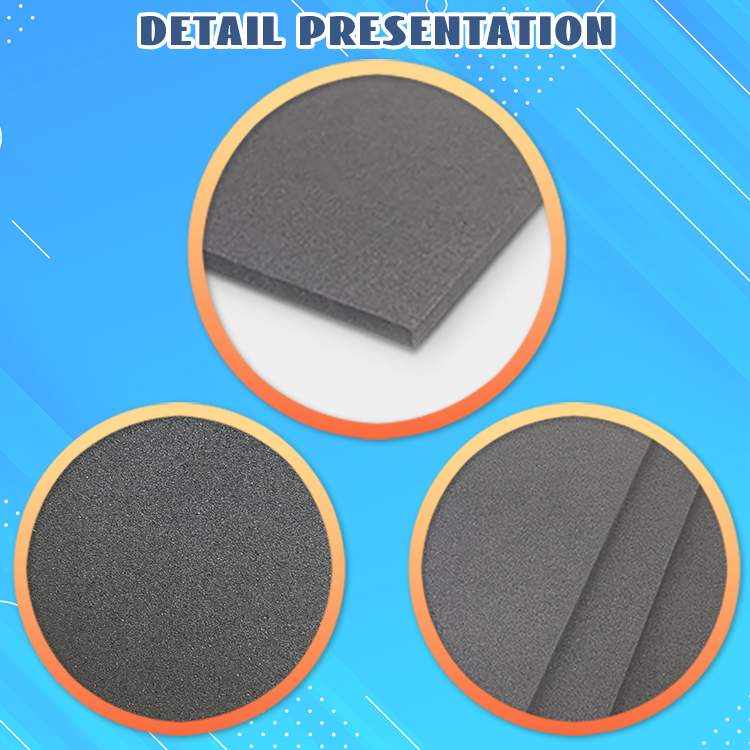

EVA sheets are shaped through various techniques such as extrusion or molding. Anti-slip textures that increase grip are added in this stage. Techniques may vary in relation to the texture and application.

2.3 Anti-Slip Treatment Application

These are further treated by other surface treatment methods and coated for improving their anti-slip property. Further, these need treatments for enhanced traction and safety features.

2.4 Quality Assurance and Testing

Quality assurance is precisely done through stringent testing to ensure anti-slip properties come up to the required standard. Routine quality control checks are made throughout the manufacturing process to maintain consistency in the product.

3. Benefits of Anti-Slip EVA Sheets

3.1 Enhanced Safety Features

Anti-slip EVA sheets have the essential safety implications in the aspects of not slipping and falling. Since they are in high-traffic or hazardous areas, that shows how important they can be in keeping in mind safety.

3.2 Durability and Performance

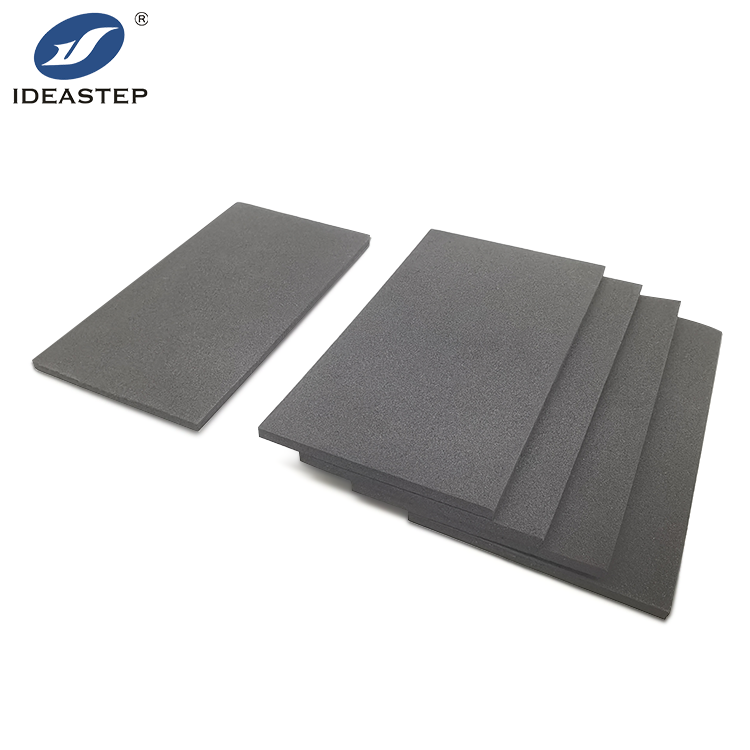

Anti-slip versions are much more durable and perform better as compared to the non-treated EVA sheets. Thus, this feature keeps it cost-effective from both the manufacturer and customer’s side.

4. Anti-Slip EVA Sheet Applications

4.1 Industrial and Commercial Purposes

Anti-slip EVA sheets also find their application in industrial and commercial fields with very high demand, ensuring safety and reliability in areas such as flooring, mats, and protection equipment.

4.2 Consumer Products and Everyday Use

Anti-slip EVA sheets can be used for consumer products such as footwear and yoga mats. This consistent grip offered by anti-slip EVA sheets will help enhance user comfort and safety.

5. Future Trends and Innovations

5.1 Advancements in Anti-Slip Technology

Future development related to anti-slip EVA sheets will be involved in manufacturing technologies and material development. New innovations are targeting the enhancement of performance and the extension of applications.

5.2 Sustainability and Eco-Friendly Practices

The trend in the production of EVA sheets focuses on sustainability issues. EVA manufacturing companies continue to explore eco-friendly materials and processes that reduce environmental impact without compromising performance.

6. Practical Application of Anti-Slip EVA Sheets

6.1 Customer’s Experience: Improvement of Safety and Performance

The reason being, as a user of anti-slip EVA sheeting, I had taken note of the substantial effort toward better safety and performance. Striking a balance between firmness and flexibility has brought about considerable fatigue reductions, boosting overall product satisfaction.

Conclusion

The following are the critical steps in the manufacturing process: selection of the raw material, testing the final product, and imparting anti-slip properties to EVA sheets. In many instances, it is indispensable because it exhibits toughness and efficiency. It guarantees safety and performances in its applications. In the future, anti-slip EVA sheets will be improved and innovated with the advancement of technology.

Frequently Asked Questions

7.1 Why are EVA sheets anti-slip?

EVA sheets are anti-slip, as additives and surface treatments enhance grip.

7.2 How does the anti-slip treatment affect the durability of the EVA sheet?

Anti-slip treatments generally enhance the functionality of the sheet without compromising much on durability; it works out for quite a long period.

7.3 What are typical applications of anti-slip EVA sheets?

Industrial flooring, protection mats, and consumer products such as footwear and yoga mats are typical applications for anti-slip EVA sheets.

7.4 Can anti-slip EVA sheets be tailor-made for specific needs?

Yes, anti-slip EVA sheets can be personalized to specific needs, such as in various textures and sizes to meet the demands of applications.

7.5 How do manufacturers ensure quality in anti-slip EVA sheets?

Manufacturers assure quality through stringent testing, quality control checks, and the maintaining of standards set by the industry throughout the course of production.

If you are interested in EVA sheet, you can continue to visit this page (https://www.eva-block.com/product/) and tell us your needs.