30mm EVA foam sheets are very versatile and resilient. Because of their great cushioning and durable features, the applications have become very common in many industries. On the other hand, their performance can be very different under extreme conditions of high temperatures, freezing cold, moisture, and even chemical exposure. This article throws some light on the performance of the 30mm EVA foam sheets in extreme conditions by shedding light on various insights, strengths, involved benefits, and ways to choose the right product for one’s purpose.

1. What Are 30mm EVA Foam Sheets?

Definition and Composition

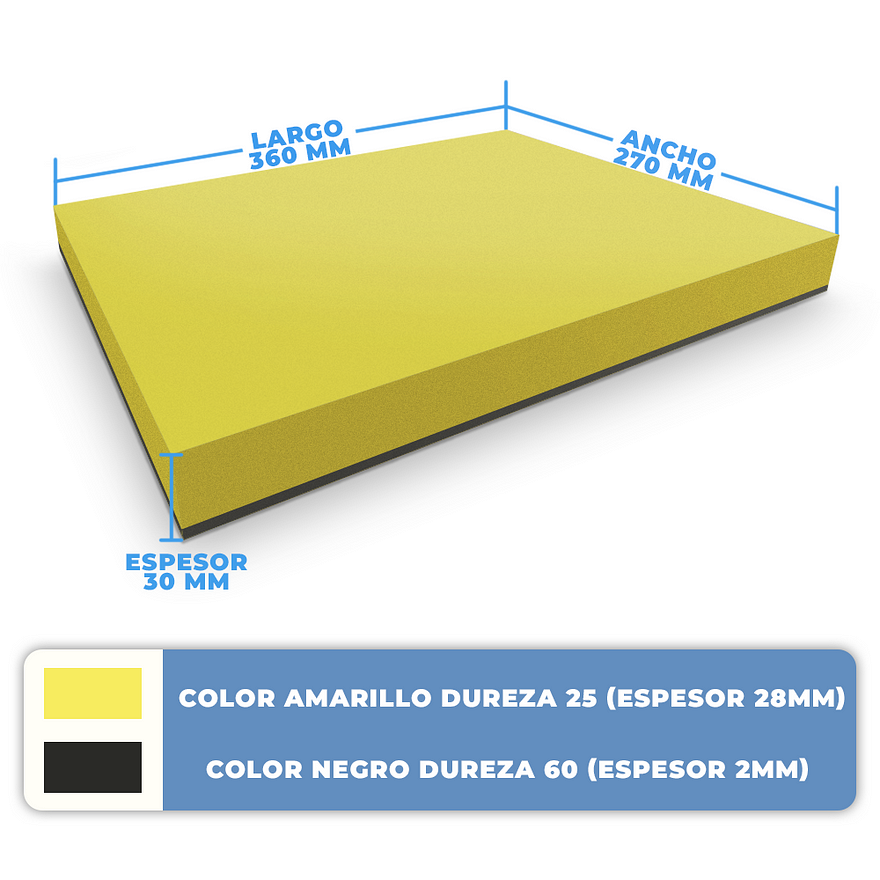

30mm EVA foam sheets are made from Ethylene Vinyl Acetate, a copolymer known for its flexibility and toughness. The thickness of 30mm provides extra cushion, hence making it suitable for a wide assortment of applications that require extra protection and support.

Typical Applications

These foam sheets see broad applications in protective padding, insulation, and cushioning for a wide range of industrial and consumer products. They find favor because of their lightweight nature, the capability for absorbing impact, and ease of customization.

2. Performance of 30mm EVA Foam Sheets Under Extreme Conditions

Heat Resistance

The 30mm EVA foam sheets do not lose their structural integrity in high-temperature settings. Because of this vital factor of heat resistance, it finds its usage in automotive interiors and industrial machinery.

Cold Resistance

Under freezing conditions, the sheets retain flexibility, having cushioning characteristics, even though they can be stiffer in extremely low temperatures. Therefore, EVA finds its applications in cold-weather gear and refrigeration applications.

Moisture and Water Resistance

Water and moisture resistance prevents associated problems such as mildew and degradation. They find very common applications in outdoor equipment and in conditions where the exposure to water cannot be avoided.

Chemical Exposure

There are various kinds of chemicals that could affect EVA foam sheets. For instance, strong acids or bases may cause degradation; hence, one has to be very precise in choosing the type of EVA foam when operating in a chemically intensive environment.

3. Essential Benefits of 30mm EVA Foam Sheets Intended for Adverse Conditions

Long Life and Good Shelf Life

The 30mm EVA foam sheets are known to be quite strong with the resistance/ non-resistance to pressure. This undoubtedly leads to their durability and the ability to retain the desired features throughout the intended life, even if the foam is to work in pretty tough conditions. This therefore would make them cost-effective and an excellent option looking at the long run.

Safety and Comfort

It also serves well in providing padding to increase safety benefits; for instance in sports materials and personal safety equipment where one might need to have cushioning. With all those performances, 30mm EVA foam sheets are economical for most applications compared with other high-performance material types.

4. Cases and Practical Examples

Industrial Applications

Industries that involve automobiles and aeronautics have 30mm EVA foam sheets playing the pivotal role of cushioning or protection. Specifically, seats, panels, and equipment in such industries make use of them to absorb shock and dampen vibration.

Consumer Products

Sports equipment, like knee pads and helmets, often make good use of the shock-absorbing quality of EVA foam sheets. They are also applied in outdoor gear, providing comfort and protection in extreme weather conditions.

Custom Solutions

Many companies have EVA foam sheets tailor-made for their specific needs, whether it be an unusual shape or color, to meet very particular environmental challenges and design requirements.

5. How to Choose the Right 30mm EVA Foam Sheet for Extreme Conditions

Assessing Your Needs

First, evaluate what the specific needs of your application are, like temperature ranges, chemical exposure, and moisture. Relate those needs to specific properties of the EVA foam sheets.

Expert Consultation

You can consult experts that deal with the EVA materials on a day-to-day basis and then contribute to you through past experiences that will assist in making a correct choice of product for your application.

Testing and Quality Assurance

Carry out different test samples of EVA foam sheets to ascertain whether such performance criteria has been achieved. The quality assurance processes will help validate the appropriateness of this material in extreme conditions.

6. Solutions to Common Problems

Handling and Maintenance Issues

Good handling and storage are vital to sustaining the performance of EVA foam sheets. Usage according to manufacturer recommendations will ensure that damages are avoided and their life extended.

Performance Challenges

By knowing the proper variant of EVA foam for prevailing conditions and by giving maintenance a run for its money, curb performance problems.

Environmental Impact

Keep the environmental impact of EVA foam sheets in mind, studying options for recycling or material substitution that would give a better sustainability profile.

7. Frequently Asked Questions

How do 30mm EVA foam sheets act in high temperatures?

30mm EVA sheets will be good to go even in high temperatures because the construction and performance of the sheet are well maintained at the high temperature.

Are 30mm EVA foam sheets resistant at freezing temperatures?

Yes, they do retain some flexibility and effectiveness when exposed to cold. However, extreme ones may make them a bit stiff.

What is the best way to maintain 30mm EVA foam sheets in extreme conditions?

Proper maintenance is done only by properly carrying out the right storage and handling according to the recommendations of the manufacturer. In this way, the foam retains its properties and increases its lifetime.

How does chemical exposure affect 30mm EVA foam sheets?

EVA foam sheets can be decomposed by chemical exposure based on the type of chemical. Environments in which there is contact with chemicals need to choose safer foams.

Customer Experience Share

I have made use of 30mm EVA foam sheets in many applications. The products have performed well in all aspects. In such a project, for example, the padding has to be durable for the support of some industrial machines. The EVA foam sheets can keep well under harsh temperatures or high impact. Most impressively, though, was how the foam would retain most of its cushioning ability under even the most extreme conditions. To be fair, another important competitive advantage in our branding was the ability to order custom colors. In general, 30mm EVA foam sheets are one versatile and dependable material useful both in industrial and consumer applications.