In today’s competitive manufacturing landscape, companies are constantly seeking ways to reduce costs while maintaining high-quality products. One material that has gained significant attention for its cost-effective properties is EVA (ethylene-vinyl acetate) foam. Widely used in various industries, EVA foam offers a range of benefits that make it an ideal choice for manufacturers looking to optimize their operations. This article will explore how EVA foam reduces manufacturing costs and provide practical B2B efficiency strategies for businesses.

Cost-Effective Material Properties

EVA foam is known for its affordability without compromising quality. It is a lightweight and durable material that can be produced at a lower cost compared to other foams. The production process of EVA foam involves fewer steps and less energy consumption, making it a more economical option. By choosing EVA foam, manufacturers can reduce their raw material costs significantly.

Streamlined Production Processes

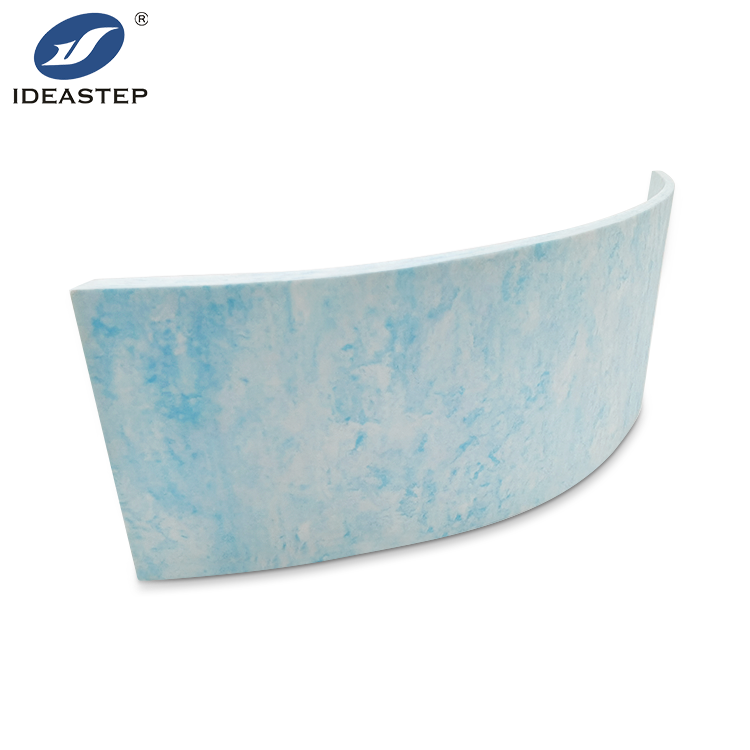

One of the key advantages of EVA foam is its ease of processing. The material can be easily molded, cut, and shaped into various forms, allowing for faster and more efficient production processes. This versatility reduces the need for complex machinery and extensive labor, further lowering production costs. Additionally, EVA foam’s compatibility with various manufacturing techniques, such as injection molding and compression molding, enhances its appeal for cost-conscious businesses.

Durability and Longevity

EVA foam’s durability translates into long-lasting products that require fewer replacements and repairs. This characteristic is particularly beneficial for industries that demand high-performance materials, such as footwear, automotive, and sports equipment. By incorporating EVA foam into their products, manufacturers can enhance the longevity of their offerings, leading to reduced warranty claims and lower after-sales service costs.

Lightweight Benefits

The lightweight nature of EVA foam contributes to reduced shipping and handling costs. Lighter products mean lower transportation expenses, which can be especially advantageous for companies involved in large-scale distribution. Furthermore, the reduced weight of EVA foam products can lead to lower energy consumption during transportation, aligning with sustainability goals and reducing overall carbon footprints.

Enhanced Product Performance

Despite its cost-effectiveness, EVA foam does not compromise on performance. It offers excellent cushioning, shock absorption, and insulation properties, making it a preferred choice for various applications. Whether used in footwear insoles, protective gear, or packaging materials, EVA foam enhances the overall quality and performance of the end products. This combination of affordability and performance ensures that manufacturers can deliver value to their customers without breaking the bank.

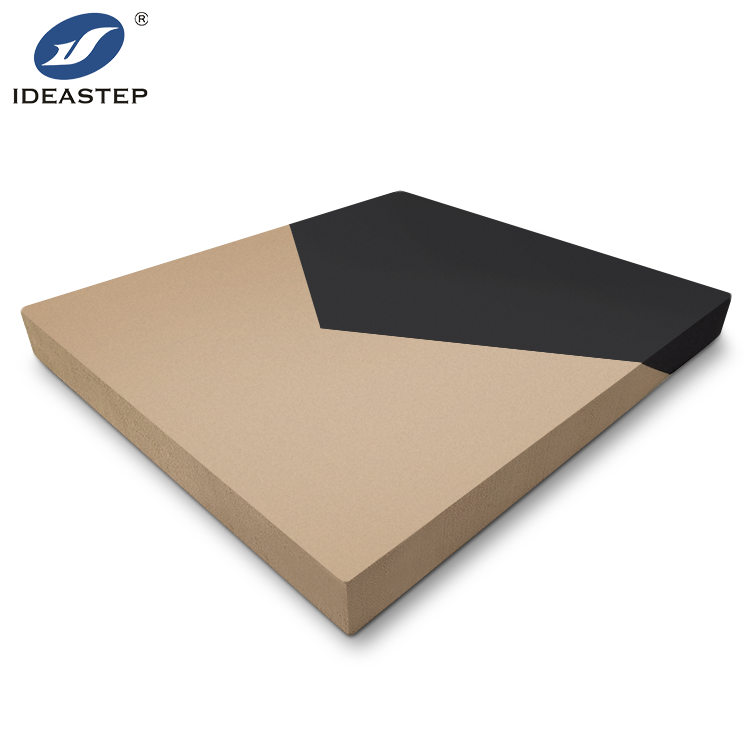

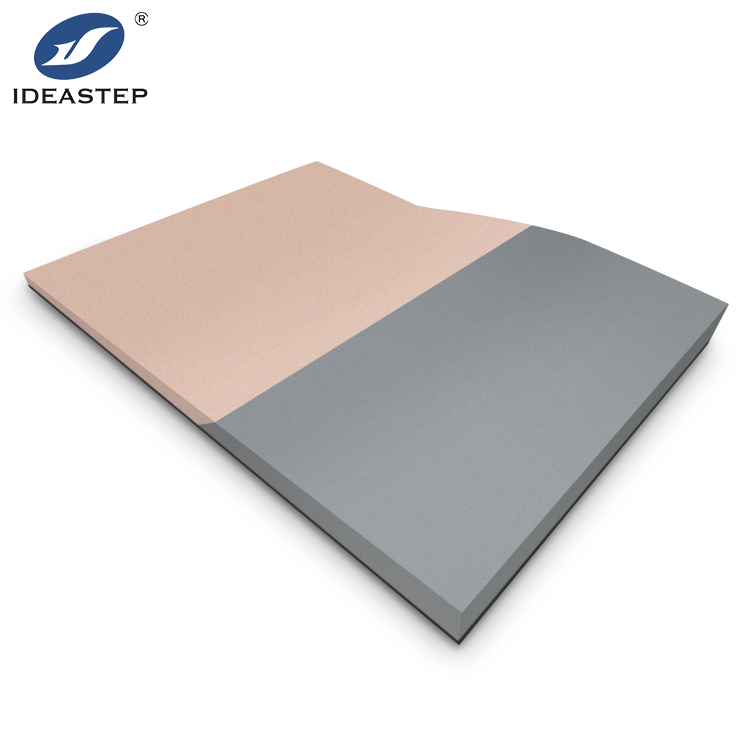

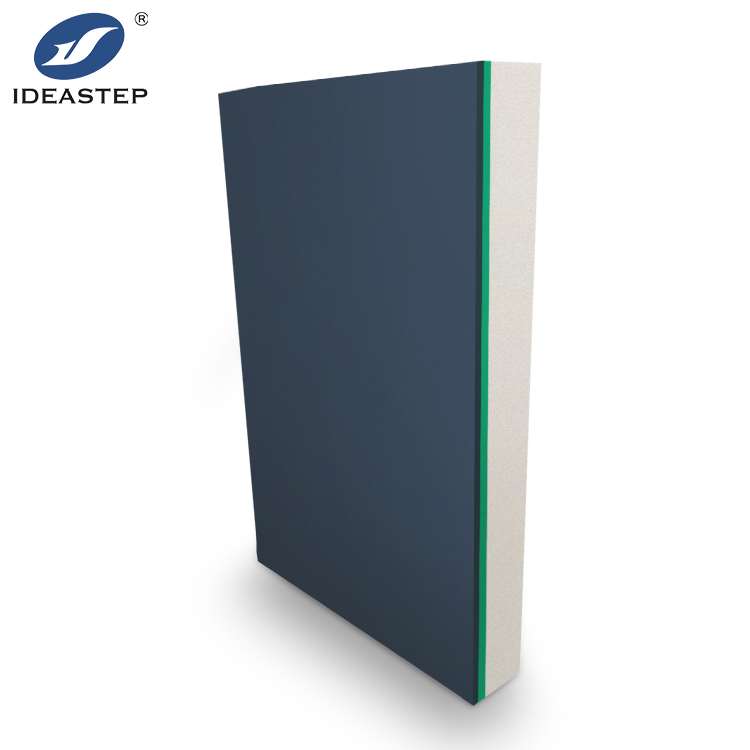

Customization and Versatility

EVA foam’s versatility allows for easy customization to meet specific product requirements. Manufacturers can tailor the foam’s density, thickness, and other properties to suit their needs, resulting in highly efficient production processes. This flexibility reduces waste and minimizes the need for additional materials, contributing to overall cost savings.

B2B Efficiency Strategies

For businesses looking to maximize the cost-saving potential of EVA foam, implementing the following B2B efficiency strategies can be beneficial:

- Bulk Purchasing: Buying EVA foam in bulk quantities can lead to significant discounts and reduced per-unit costs. Establishing long-term supplier relationships can further enhance these savings.

- Lean Manufacturing: Adopting lean manufacturing principles can streamline production processes and minimize waste. By optimizing the use of EVA foam and reducing unnecessary steps, businesses can achieve greater efficiency and cost savings.

- Collaborative Design: Collaborating with suppliers and customers during the design phase can lead to more efficient use of EVA foam. Understanding the specific needs and preferences of stakeholders allows for better material utilization and reduced production costs.

- Automation: Investing in automation technologies can enhance the precision and speed of EVA foam processing. Automated cutting, molding, and assembly processes reduce labor costs and increase production capacity.

- Recycling and Reuse: Implementing recycling programs for EVA foam waste can lead to cost savings and environmental benefits. Recycled EVA foam can be used in various applications, reducing the need for new raw materials.

Conclusion

EVA foam offers a multitude of benefits that contribute to reduced manufacturing costs. Its affordability, ease of processing, durability, and lightweight nature make it an ideal choice for businesses aiming to optimize their operations. By implementing B2B efficiency strategies, manufacturers can fully leverage the cost-saving potential of EVA foam, leading to increased competitiveness and profitability. Ideastep, as a leading supplier of EVA foam products, continues to support businesses in achieving their cost reduction goals through innovative solutions and high-quality materials.