EVA foam sheets have gained wide popularity among a number of industries for their versatility, toughness, and flexibility. However, one critical aspect that is crucially affecting both the performance and applicability of EVA foam sheets lies in the thickness of the sheets themselves. This article points out how different thicknesses of EVA sheets affect the manufacturing process by ranging from cutting and shaping to quality control, and how choosing an appropriate thickness can result in better product results.

1. Introduction: Importance of EVA Sheets Thickness during Manufacturing

EVA sheets boast uniqueness in many industries, including automotive, footwear, and packaging, amongst others. The thickness of the EVA sheets, however, is considered pivotal during the application of such sheets in different areas. How such thickness would affect manufacturing is an important aspect in the optimization of business process techniques that relate to the offering of quality products at the end.

2. Understanding EVA Sheets Thickness and Importance

2.1 What is the Thickness of EVA Sheets?

The thickness of an EVA sheet is the millimeter measurement of how thick the foam material is. This is basically the thickness of the sheet, dictating what application it can be used for since it defines the level of flexibility, cushioning, and insulation provided.

2.2 Why Does EVA Sheets Thickness Matter in Manufacturing?

Since EVA sheets’ thickness has a great impact on the performance of sheets at their final application, the selection of the right thickness is crucial at the time of manufacture. Indeed, the thickest sheets tend to be stronger in durability and cushioning, but tend to be less flexible, whereas the thinner sheets are more flexible. This is where manufacturing companies have to put into consideration the intended use and select the right thickness for their products.

3. Effects of EVA Sheets Thickness on Production Techniques

3.1 Techniques of Cutting and Shaping for Different EVA Sheets Thickness

Different thickness requires specific techniques of cutting and shaping to ensure precision and integrity of the material. Thicker sheets may require stronger cutters, while thinner sheets require delicacy to prevent damage.

3.2 Adhesion and Bonding Challenges with EVA Sheets of Different Thicknesses

With EVA sheet bonding, thickness may pose a problem. Thicker sheets may require stronger adhesives or means of bonding to fit well, while thinner sheets may peel off or separate easily if not bonded appropriately.

3.3 Importance of Thickness of EVA Sheets in Heat and Pressure Forming Processes

Considering the thickness of EVA sheets, their response to heat and pressure will also differ in different forming processes: thicker sheets would require more heat or pressure to mold, while thinner sheets form easily but might distort if not handled correctly.

4. Quality Control and Consistency in EVA Sheets Thickness

4.1 Maintaining Consistent Thickness Across Production Batches

This requires consistency in thickness as a means to ensuring quality within various batches of production. The companies utilize advanced machinery that is fitted with regular inspections to ensure each sheet keeps up with the same thickness since this is very important to meet customer specification.

4.2 Checking Thickness of EVA Sheets for Quality Assurance

Quality assurance demands frequent checks on the thickness of EVA sheets. The manufacturing companies employ all sorts of tools and ways of measurement for exact thickness so that the final product will turn out as desired.

5. Case Study: How Ideastep Ensures Optimal EVA Sheets Thickness

5.1 Ideastep’s Approach to Customizing EVA Sheets Thickness

Ideastep is an EVA leading sheets supplier that customizes the thickness as required by customers. With advanced techniques of production, there is perfect thickness control, hence giving the best quality amongst products.

5.2 Real-world Application: Customer Success Stories

In this respect, Ideastep has been successful in many projects related to EVA sheets thickness optimization. Several customers reported an attainment of better performance and longevity for their products upon receipt of exactly thick EVA sheets from Ideastep.

6. Overcoming Common Challenges with EVA Sheets Thickness in Manufacturing

6.1 Dealing with Variations in EVA Sheets Thickness

Inconsistent thickness will cause a variety of problems during manufacturing, such as uneven cuts or bad bonding. Because of these challenges, manufacturers have to be very conscious of quality control in order for all sheets to be produced in consistent thickness.

6.2 Solutions to Maintain EVA Sheets Thickness in Large-Scale Production

This is relatively hard to achieve because most of the methods have specific limitations which make maintaining consistent thickness difficult in large-scale production. However, there are appropriate techniques and equipment that allow manufacturers to overcome these challenges. Maintenance of equipment regularly and optimization of processes ensure the production is consistent in quality.

7. Customer Experience: My Experience with Ideastep’s EVA Sheets

I have had numerous projects that involve the use of EVA sheets from Ideastep, and I can confidently assure you of their commitment to preciseness in the thickness of their sheets; this really made a difference in the quality of our products. The consistent thickness ensures good adhesion, good accuracy in cutting, and an overall good performance of the products. Their attention to detail, coupled with customer satisfaction, makes Ideastep the best option for any EVA sheet.

8. FAQs About EVA Sheets Thickness in Manufacturing

8.1 How thick should EVA sheets be to function well in footwear manufacturing?

Optimal thickness for EVA sheets to be used in footwear production ranges from 3mm to 6mm, depending on the level of cushioning and flexibility desired.

8.2 How will thickness impact durability with regards to EVA sheets?

Thicker sheets are generally stronger, given that this increases their depth to absorb shocks and provide resistance against abrasion over time.

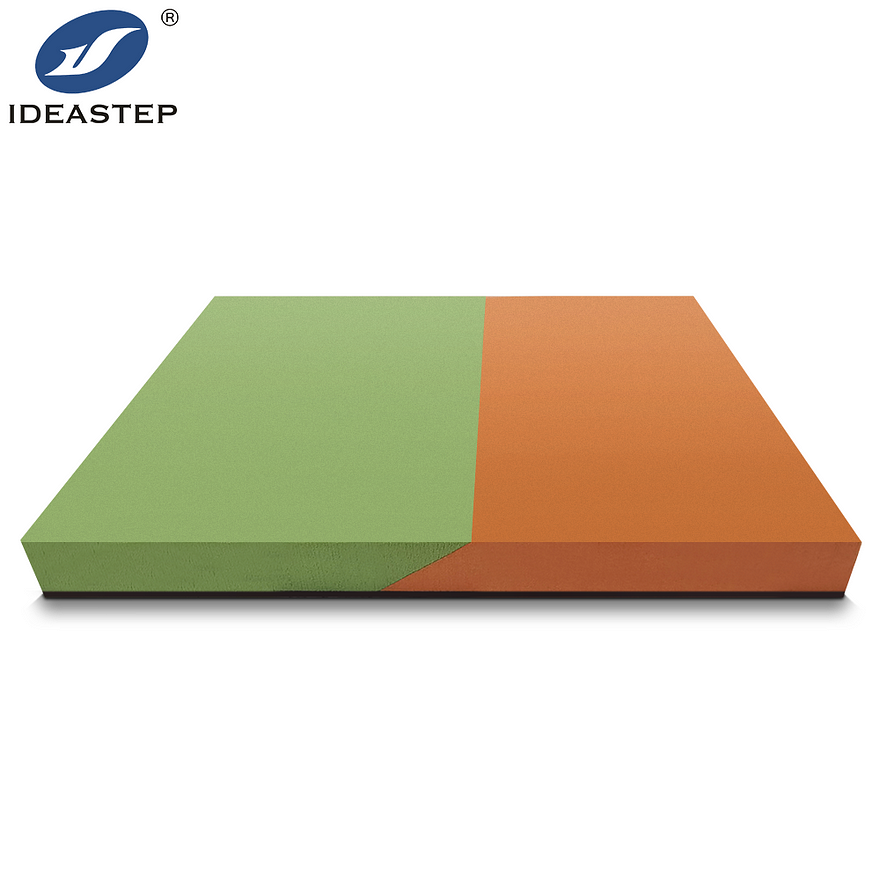

8.3 Can EVA sheets of different thicknesses be combined?

Yes, EVA sheets of different thicknesses can be combined in layers or together in ways so that added characteristics can be achieved, such as added cushion or support.

8.4 What is the standard range that EVA sheets’ thickness follows for packing?

The EVA sheets used for packing start at 1mm and go up to 10mm depending on the protective needs.

8.5 How do the manufacturers keep thickness consistency in EVA sheets?

Manufacturers keep the thickness consistency for each EVA sheet with the help of advanced machinery and quite frequent quality control checks, which assure uniformity and follow customer requirements.

If you are interested in EVA cover sheets , you can continue to visit this page (https://www.eva-block.com/product/) and tell us your needs.