The safety of EVA blocks in manufacturing characterizes the levels of product integrity that will be very instrumental in protecting the end-users. EVA blocks are designed to be applied in industries such as manufacturing, in which this particular material bears all characteristics of durability and versatility. In case they are not well handled or are made from poor materials, they pose a huge risk. The article below dictates the guidelines and best practices necessary to assure safety, from quality control to compliance with industry standards in EVA blocks.

Understanding EVA Blocks

What Are EVA Blocks?

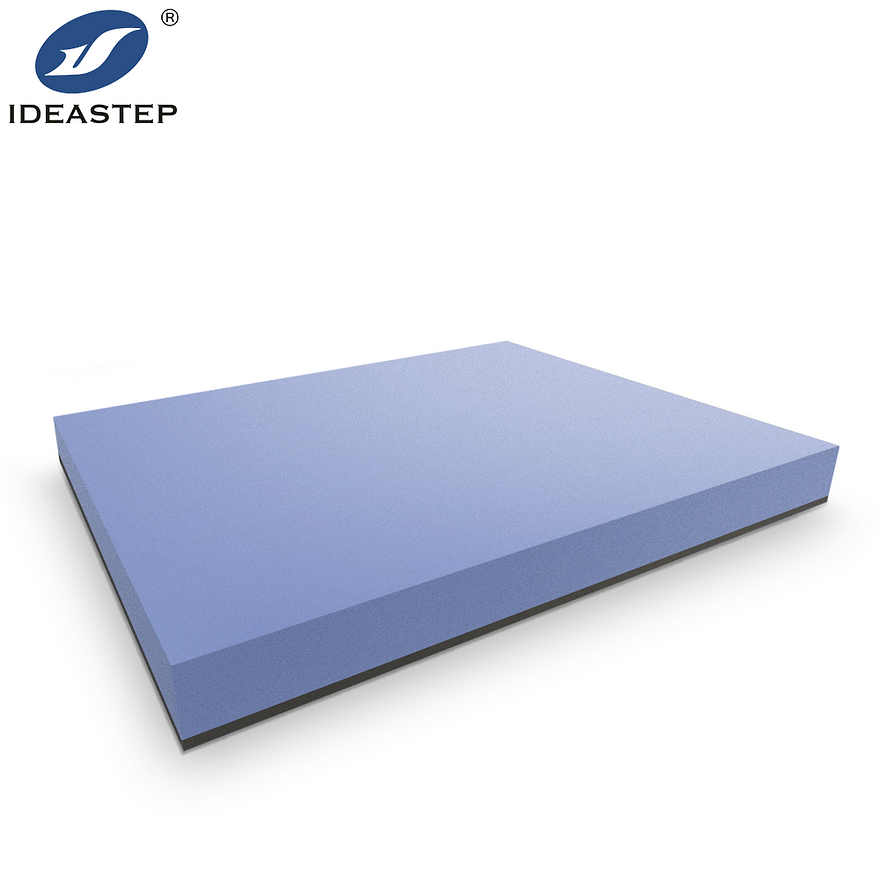

EVA is short for Ethylene Vinyl Acetate blocks. They are soft and flexible, and commonly used for shock absorption in the manufacturing industry. They are highly versatile and useful for durability and cushioning in various industry applications: footwear, automotive, and sports equipment.

Worth of Safety

EVA blocks need to be safely handled and used to ensure consequential problems and unsafe conditions are not created due to poor material or handling practices. Ensuring safety in using EVA blocks can avoid consequential problems such as deteriorated materials and malfunctioning products.

Quality Control

Sourcing Quality EVA Blocks

Authentic suppliers should be gotten in the sourcing of EVA blocks to guarantee that safety is assured. Only those whose history is good in the provisions of quality material are to be hired, with the certificates and test procedures verified in the process. Sourcing the material will thus be the first step in the mitigation of the risks of EVA blocks.

Testing and Verification

Apart from that, regular testing and verification should be the norm: the safety of the blocks is to be maintained as per the standards. Introduce some of the major tests like material integrity tests and performance evaluations in the blocks to maintain the level of safety to meet required standards. This is also part of routine quality checks under the standard operating procedures.

Best Practices for Safe Handling and Storage

Handling Techniques

The minimum degree of damage shall be caused during handling. Provide all tools and techniques necessary to prevent physical damage to EVA blocks. Ensure your personnel know proper handling techniques that avoid contamination and keep the blocks in the best condition possible.

Storage of EVA Blocks

Controlled environment away from extreme temperature and humidity for storage of EVA blocks. Inventory and housekeeping should be maintained to ensure safety and avoid accidents.

Compliance with Safety Standards

Relevant Industry Standards

Industry norms play a vital role in the safety of EVA blocks. A clear understanding of the prevalent regulations and guidelines in the industry is required, where compliance is to be pursued for each manufacturing process. Periodic check and update of safety protocols are compatible with the latest standard.

Regular Audits and Reviews

Conduct safety audits periodically to evaluate practice compliance against safety standards. Regular reviews offer a platform for noting practices potentially risky and areas that could be worked on in order to ensure continued safety and quality concerning the use of EVA blocks.

Safety Protocols Implementation

Development of Safety Protocols

Eva Block Safety protocols dealing to any regard, starting from receiving and storage to processing and use, shall be fully developed. Staff shall be fully trained upon such a scenario for a safe working environment.

Response to Emergencies

Clearly detail procedures for responding to safety incidents of EVA blocks. The preparation for possible emergencies and planning in that regard is of prime importance, so that risks can be at a minimum, allowing for rapid, effective response.

Conclusion

Manufacturing of EVA blocks should be done safely; these blocks are important for good quality products and to protect the users. Below are the guidelines and best practices; following these will ensure the EVA blocks will meet the safety stipulations and serve in their function with consistency. Strict quality control, proper handling and storage practices, and compliance with the standards within the given industry will contribute a lot to safe, efficient manufacturing.

FAQs

What steps will you take to check if EVA blocks are quality enough for use?

Conduct tests on materials to check integrity and performance evaluations of the quality.

What are ideal conditions for storing EVA blocks?

EVA blocks should be stored in a controlled environment with stable temperature and stable levels of humidity.

How often would you recommend that safety audits are done in an EVA block manufacturing process?

Have a safety audit every 6-12 months, and this will ensure that already achieved compliance is maintained.

What are the important industry standards applicable to EVA blocks?

Adhere to the appropriate safety and quality standards related to the industry—such as ASTM or ISO.

User Experience Share

This is proven by the manufacturer of EVA Blocks as evidence that by adhering to strict quality control and safety, it has greatly improved product consistency and safety. Regular inspection and ensuring that the products meet the set standards in the industry have reduced the risks and improved the quality of products according to expectations.

The comprehensive approach to EVA block safety in manufacturing is the key to high standards and quality products.