Choosing the right EVA CAD CAM milling blocks is essential for achieving optimal performance in your specific field. This guide provides comprehensive tips on selecting the best EVA blocks to meet your precise needs and ensure efficiency in your operations.

Understanding EVA CAD CAM Milling Blocks

EVA (Ethylene Vinyl Acetate) CAD CAM milling blocks are essential components in various industries, particularly for applications requiring precise cutting and shaping. These blocks are used in computer-aided design and manufacturing (CAD CAM) systems to create accurate prototypes, molds, and finished products. Selecting the right EVA milling blocks can significantly impact the quality and efficiency of your work. Here’s how to choose the best EVA CAD CAM milling blocks for optimal performance in your specific field.

1. Evaluate Material Quality

The quality of the EVA material used in milling blocks plays a crucial role in the final product’s performance. High-quality EVA should offer excellent consistency in density and hardness. When choosing EVA CAD CAM milling blocks, check the material specifications provided by suppliers. Reputable suppliers, such as Ideastep, ensure that their EVA blocks meet high-quality standards, providing consistent performance across various applications.

2. Consider Block Size and Shape

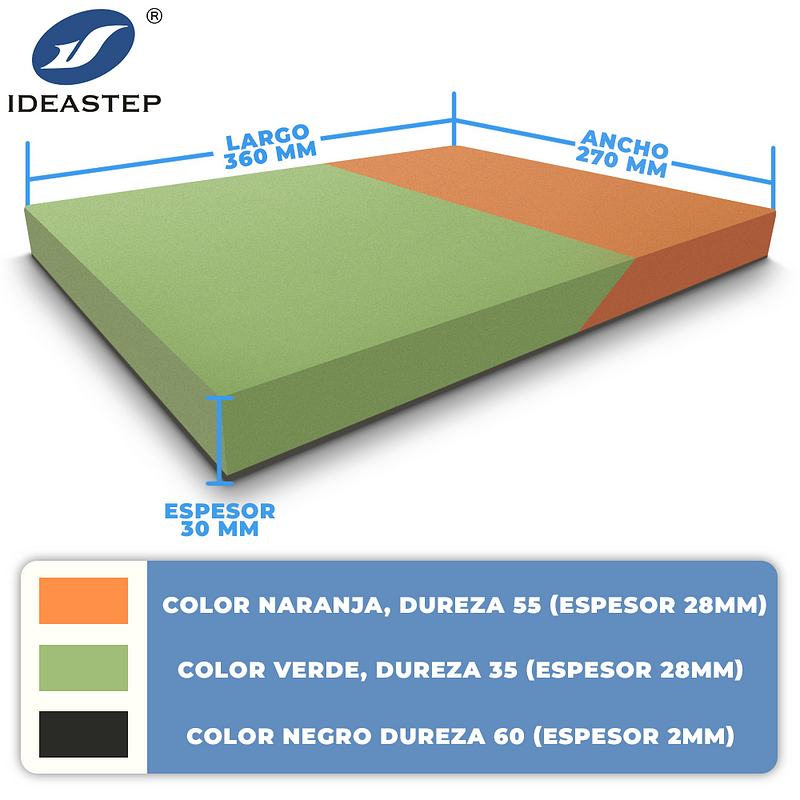

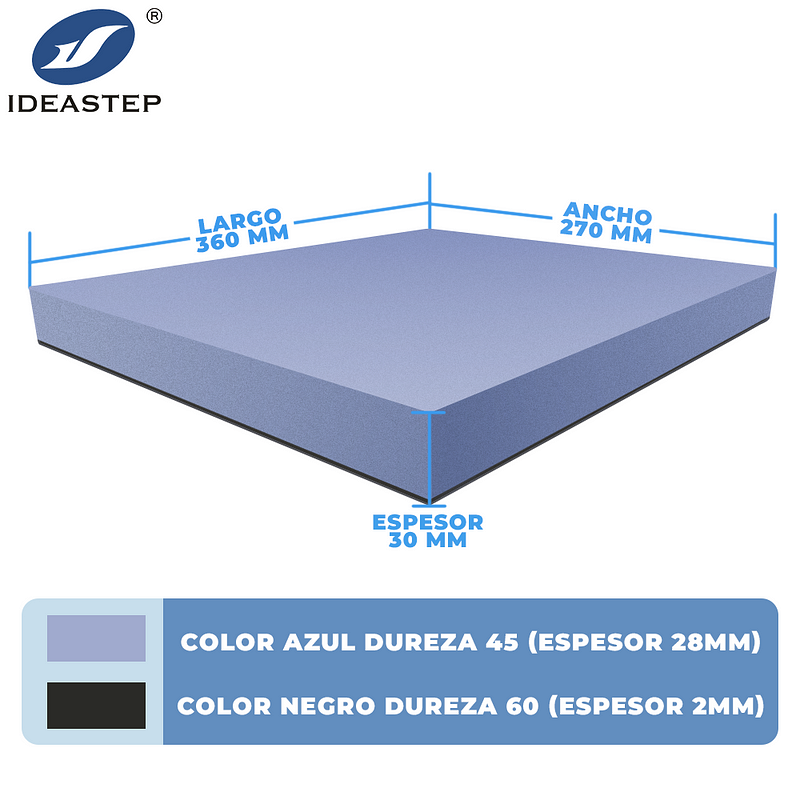

The size and shape of the EVA milling blocks should align with your specific requirements. Milling blocks come in various sizes and shapes, including rectangular, square, and custom configurations. Ensure that the blocks you select fit your CAD CAM machine and meet the dimensions required for your projects. Choosing the right size and shape will help in achieving better precision and reducing waste during the milling process.

3. Assess Milling Block Hardness

The hardness of EVA milling blocks affects their cutting efficiency and durability. Harder blocks are generally more resistant to wear and provide better performance for intricate designs. However, too much hardness might make the blocks difficult to mill. It is essential to choose a hardness level that balances performance and ease of machining. Suppliers like Ideastep can provide detailed information on the hardness levels of their EVA blocks to help you make an informed choice.

4. Check Compatibility with CAD CAM Systems

Ensure that the EVA milling blocks you choose are compatible with your CAD CAM system. Compatibility affects how well the blocks integrate with your existing equipment and software. Review the specifications of both the milling blocks and your CAD CAM system to ensure they work seamlessly together. Some suppliers offer blocks designed specifically for certain CAD CAM systems, which can enhance overall efficiency.

5. Evaluate Surface Finish and Texture

The surface finish and texture of EVA milling blocks influence the quality of the final product. Smooth and uniform surfaces are crucial for producing high-quality prototypes and molds. Inspect the surface quality of the blocks before purchase to ensure they meet your standards. High-quality suppliers like Ideastep often provide samples to evaluate surface texture, helping you make an informed decision.

6. Consider Cost and Value

While cost is an important factor, it should be balanced with the value offered by the EVA milling blocks. Cheaper blocks may not always provide the best performance or durability. Compare prices among different suppliers, including Ideastep, and evaluate the overall value provided by the blocks. Consider factors such as material quality, performance, and additional features to ensure you are making a cost-effective choice.

7. Review Customer Feedback and Testimonials

Customer feedback and testimonials can provide valuable insights into the performance and reliability of EVA milling blocks. Look for reviews from users in similar industries to gauge how well the blocks perform in real-world applications. Positive feedback and high ratings can indicate a reliable product, while negative reviews might highlight potential issues. Reputable suppliers often have customer testimonials available for review on their websites.

Conclusion

Choosing the right EVA CAD CAM milling blocks involves evaluating material quality, block size and shape, hardness, compatibility with CAD CAM systems, surface finish, and cost. By carefully considering these factors and consulting with reputable suppliers like Ideastep, you can select the optimal EVA milling blocks that enhance your performance and efficiency. Making an informed decision ensures that your milling operations meet high standards of precision and reliability.

FAQ

1. What is the importance of EVA milling block hardness?

The hardness of EVA milling blocks affects their cutting efficiency and durability. Harder blocks generally offer better resistance to wear and are suitable for detailed work. However, very hard blocks may be challenging to mill. Choosing the right hardness ensures a balance between performance and ease of machining.

2. How can I determine the right size of EVA milling blocks for my project?

To determine the right size of EVA milling blocks, consider the dimensions of your CAD CAM machine and the requirements of your project. Select blocks that fit your equipment and meet the necessary dimensions to ensure precision and minimize waste.

3. Are there any specific brands known for high-quality EVA milling blocks?

Yes, there are several reputable brands known for high-quality EVA milling blocks. Suppliers like Ideastep are well-regarded for their consistent product quality and performance. It is advisable to review customer feedback and product specifications to choose a reliable brand for your needs.