Introduction

The right EVA foam sheet rolls can make or break custom prototyping. EVA foam is one of the resources that are light in weight, flexible, and durable. For such benefits, this foam has easily become a favorite material for many applications. As such, herein is a guide to help you come up with the right decision on the essentials to decide on an EVA foam sheets roll for your custom prototypes, ensuring cost-effectiveness and appropriateness in performance.

1. What is EVA Foam, and What are EVA Foam Sheet Rolls?

EVA (ethylene-vinyl acetate) foam is that almost universal material in most applications, due to its softness, pliability, and shock-absorbing properties. Sheets of EVA foam roll come in various grades and densities, all customized for different needs. Compromise on the level of each of these characteristics the grades of foam might display in order to make the most ideal pick for your foam prototype.

Sheets of EVA foam rolls come in different qualities, densities, colors, as well as thicknesses. The greater level of foam density provides better strength and support, and less provides more flexibility. Choose the kind that would be in accordance with what your prototype demands.

2. Things to Consider When Purchasing EVA Foam Sheet Rolls

Use and Application

You have intended the use for your prototype, and you can determine the kind of EVA foam you want. For example, you may be looking for your prototype to require high shock absorption. In such a case, you use a high-density foam. On the other hand, if it’s necessary for applications where flexibility is required, a lower-density foam would be ideal for you.

Thickness and Density

Thickness controls, apart from density, even play a crucial role for the performance of the EVA foam. More thick foams will feel softer; however, varying densities make them relatively rigid and give them support. Ensure these are as per your prototype demands.

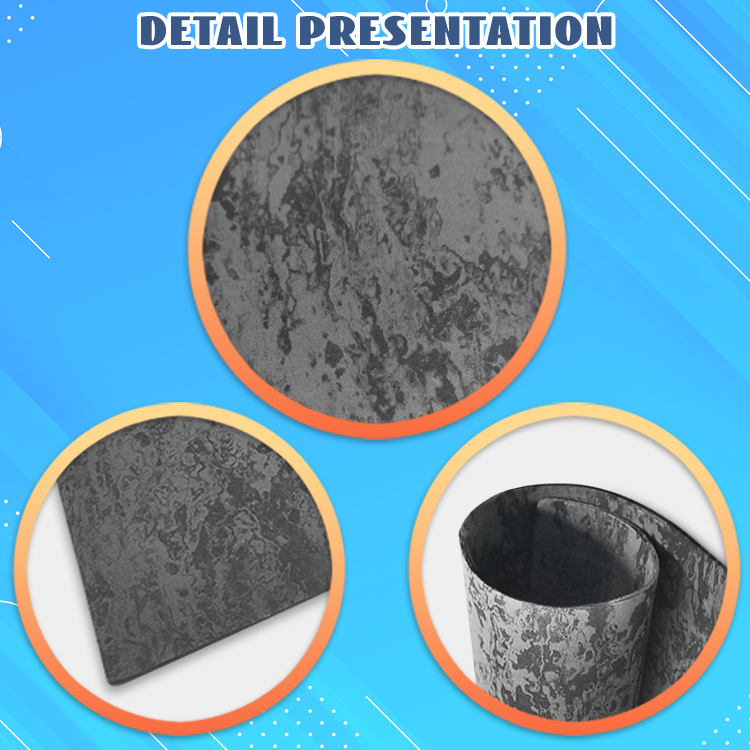

Surface Texture and Finish

EVA foam sheets rolls come in different surface textures and finishes. You may require a smooth finish or a textured surface, depending on aesthetic and functional needs. Consider how such finishes might impact your prototyping project.

3. Evaluation of Quality and Specification

The Quality Standards and Certifications

Ensure the EVA foam you would use adheres to industry standards, such as ASTM or ISO. These will be a confirmation that the foam follows quality and performance standards and are important in ensuring your prototype is indeed long-lasting and reliable.

Supplier Reputation and Reliability

Source your EVA foam sheet rolls from reputable suppliers like Ideastep. Such a supplier can assure you the credibility of materials and assist you in your project. Check customer reviews and industry reputation to ensure the reliability of the supplier.

4. Considering the Costs

Budget for Custom Prototyping

The balancing of cost with quality is paramount. It’s always tempting to go for what is cheapest. But first, check on performance and durability. Go for value solutions that are low-priced but not cheap.

Bulk vs. Small Quantity Orders

Buying the EVA foam in bulk will save some money even though you may spend a little more on the initial investment. The orders for small quantities are flexible; however, a higher cost per individual unit is possible. Make a choice appropriately with the size of the project you have at hand and with the budget.

5. Sample Testing and Prototyping

Request a Sample

Always ask for samples first before a bulk quantity purchase. By testing the samples, you can judge the foam material for your product prototype. Look out for texture, density, and overall quality.

Checking Compatibility

Run foam samples against prototype specifications to check compatibility. You do not want any compatibility issue tearing down the overall performance such as the wrong density or wrong texture.

6. Environmental and Safety Considerations

Sustainability and Eco-Friendly Options

Consider eco-friendly EVA foam options in case of sustainability. It would be responsible if a person evaluated environmental impact from the foam and the supplier’s practice.

Safety and Compliance

Ensure that EVA foam is safe for use and complies with the regulations. Avoid compliance problems by checking for health and safety issues that could relate to the foam.

Conclusion

Choosing the right EVA foam sheet rolls for prototyping involves understanding material properties, application needs, and budget considerations. By carefully evaluating these factors and selecting a reputable supplier, you can ensure your prototypes meet your project requirements effectively.

Frequently Asked Questions

What are some of the things one has to consider when selecting EVA foam sheet rolls for prototyping?

Consider thickness, density, and the specific application requirements of your prototype.

How do I know what’s the correct density and thickness for my project?

The ideal density and thickness will depend on your prototype’s performance needs, like cushioning or rigidity.

What are the benefits of ordering sample items before I place an order for a large volume?

Samples enable you to pretest the suitability and quality of the foam before you commit to purchasing a large quantity.

Are there any environmentally friendly options for EVA foam sheet rolls?

Yes, there are environmentally friendly EVA foam solutions. Look for materials carrying a certification for sustainability, and enquire about the practices of your suppliers.