Introduction

EVA foam, which is mainly referred to as ethylene vinyl acetate foam, is a general-purpose material with some of the greatest flexibility, cushioning, and durability characteristics. It has a wide variety of applications in products such as footwear, packaging, and cushioning products. EVA foam has to be determined with the right density so that its performance and ability to serve a purpose can be maximized for various needs. Perfect density ensures that the foam meets your product’s specific needs.

1. EVA Foam Overview

What is EVA Foam?

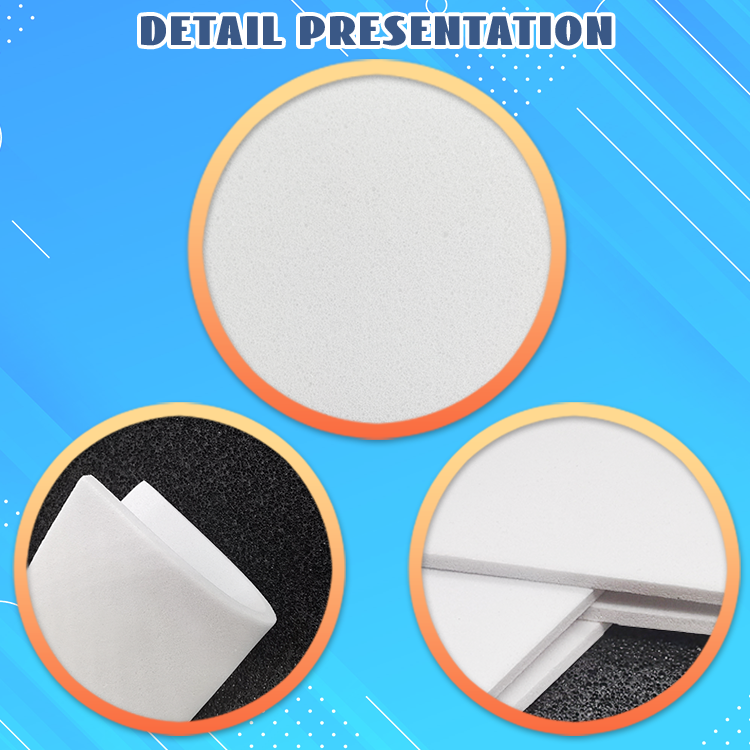

EVA foam is a copolymer comprising olefin and vinyl acetate. The properties which are associated with EVA foam include light weight due to being flexible and can also be resistant against impacts. These properties establish its effectiveness for a wide variety of uses.

Main Properties of EVA Foam

The major properties are softness, flexibility, strength, resilience to strike, and absorption of shocks. These properties make EVA foam popular for requirements that demand cushioning and resilience.

2. The Role of Density in EVA Foam

What is Density in EVA Foam?

Density refers to the mass of a material for every unit volume in EVA foam. It is known to affect the firmness of the foam, its cushioning ability, and performance. Normally, the more the density level, the firmer the foam would be, but in a lower density level, the foam would be softer and more flexible.

How Density Affects Performance

The difference in the densities of EVA foams will affect both cushioning/comfort and performance/life. The use of high-density foams applies where good support or resistance to shock is necessary. Lower density foams offer more comfort and flexibility.

3. Choosing the Right Density for Your Needs

Determine the Needs of Your Application

Base your needs on the application of the EVA foam. If it is going to be used on footwear, packaging, or cushioning, that way you can determine what the right density would be.

EVA Foam Types Densities and Their Uses

Common densities are from low to high each recommended differently to be utilized. For example, low-density foam is used for soft cushioning, but high-density foam is used for impact protection and structural support.

Factors to Consider

The environmental conditions such as the temperature and humidity under which the material will work, the load bearing requirements, and the required comfort level mainly determines the density to use of EVA foam. These crucial factors can help ensure that the foam can work appropriately in the application.

4. Testing and Validation

Sample Testing

Test some sample foams before making a decision. You are going to learn, through testing how different densities perform in life-like conditions and whether they will be suitable for your needs.

Performance Evaluation

Compare each foam density’s performance against product quality, durability, and comfort. Real-world testing will help you confirm that the chosen foam density matches the requirements of your product.

5. Common Problems and Solutions

Incompatibility with Existing Systems

Be sure that the selected EVA foam density should be compatible with your production processes. If not, then one might need to do some changes in order to incorporate the foam nicely in the systems.

Cost Consideration

While selecting EVA foam, balance the cost against performance requirements. Different densities can have an impact on overall costs, so weigh both quality and budget when making a selection.

6. Conclusion

Prime importance is in the selection of the optimum density of EVA foam to derive the best performance for the application. Major factors that contribute to that choice are the application requirements, characteristics of the foams, and results of testing.

Final Recommendations

Try out the different densities of EVA foam when you know what you need. That way, you will be perfectly convinced that your product benefits from the ideal match of cushioning, support, and durability.

Frequently Asked Questions

What is considered the best density for EVA foam in footwear?

The best density for EVA foam can vary, but it likely depends on the specific application you want. Applications can vary between high density for support, and low density for cushioning.

How can I test EVA foam density before purchase?

This test is conducted for the sample that was tested in real-life use to make sure it meets the specified properties.

What cost implications might there be from the different densities of EVA foam?

EVA foam densities are likely to create different cost issues in some cases. Higher density foams are sometimes more costly but provide an added value of durability and support, while lower density foams might add to cost savings, with softness being often less important.

Can EVA foam of different densities be used homogeneously for the product?

Yes, EVA foam of different densities can be used homogeneously in the product to strike a right balance between comfort, support, and performance. This provides an approach in which customization lies at a specific need.