If you want to get high-quality results from your projects, choosing the right supplier of EVA foam sheets for precise cutting and shaping is essential. This guide provides fundamental tips on how to pick a provider that meets your accuracy needs and ensures optimal performance.

How to Choose the Right EVA Foam Sheet Supplier for Precision Cutting and Shaping

Choosing the right supplier for EVA (Ethylene Vinyl Acetate) foam sheets is fundamental when precision cutting and shaping are required. The accuracy and durability of your final product are significantly enhanced by using high-quality EVA foam sheets. To select a supplier that can meet your specific requirements with exceptional precision and performance, this guide provides useful insights.

1. Grasp Your Precision Requirements

Prior to choosing a provider, understanding your particular precision requirements is crucial:

- Application Needs: Identify exactly what your project needs. Whether you require EVA foam sheets for intricate designs, custom shapes, or specific thicknesses, knowing your needs will guide your provider choice.

- Accuracy in Cutting and Shaping: Determine the level of accuracy required for cutting and shaping. Some projects demand exact dimensions and complex details, which require high precision from the provider.

- Material Specifications: Ensure the supplier can provide EVA foam sheets with the desired properties, such as density, hardness, and color, to fulfill your project’s requirements.

2. Assess Potential Suppliers’ Capabilities

It is essential to evaluate potential suppliers’ capabilities to ensure they can meet your precision requirements:

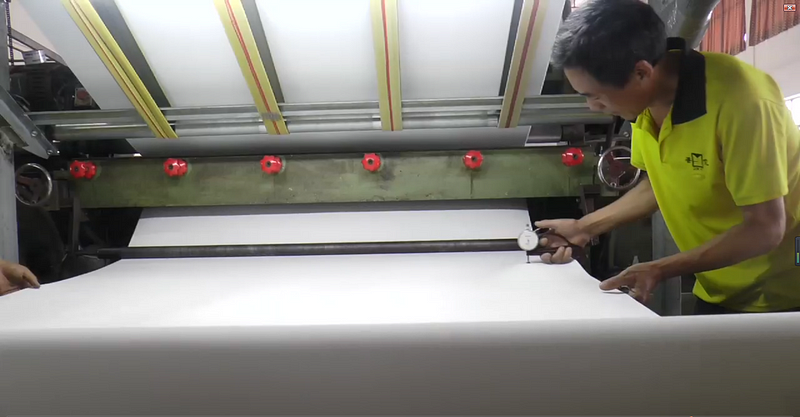

- Cutting Technology: Verify if the supplier utilizes advanced cutting technologies such as CNC machines or laser cutters, which are necessary for high-precision cutting and shaping.

- Shaping Techniques: Assess the provider’s ability to perform complex shaping techniques. Suppliers experienced in custom molding and shaping are better equipped to handle intricate designs.

- Quality Control: Inquire about the supplier’s quality control procedures. A reputable supplier should have stringent quality checks to ensure that the EVA foam sheets meet the required precision standards.

3. Consider Provider Experience and Reputation

Experience and reputation are significant factors in choosing a reliable provider:

- Industry Experience: Choose a provider with substantial experience in the EVA foam industry. Experienced suppliers are more likely to understand the nuances of precision cutting and shaping.

- Customer Reviews and Testimonials: Review customer feedback and testimonials to gauge the supplier’s reputation. Positive reviews and satisfied clients can indicate a trustworthy provider.

- Previous Projects: Request examples of previous projects or case studies. Suppliers who have successfully handled similar projects can demonstrate their capability to meet your precision needs.

4. Assess Support and Communication

Effective support and communication are critical for a successful partnership with your supplier:

- Customer Service: Evaluate the quality of the supplier’s customer service. A responsive and knowledgeable customer support team can address your queries and concerns promptly.

- Technical Support: Ensure the supplier offers technical support for any issues that may arise during the cutting and shaping process. Technical assistance can help resolve problems quickly and effectively.

- Communication Channels: Check the communication channels available for interacting with the supplier. Clear and open communication is essential for ensuring your requirements are accurately understood and met.

5. Compare Prices and Terms

While price should not be the only factor in your decision, it is important to compare pricing and terms:

- Pricing: Compare the pricing of different suppliers to ensure it fits your budget. Consider both the cost of the EVA foam sheets and any additional charges for precision cutting and shaping.

- Terms and Conditions: Review the supplier’s terms and conditions. Pay attention to factors such as delivery times, payment terms, and any guarantees or warranties provided.

6. Choosing the Right Supplier

By considering these factors, you can select a supplier that meets your precision requirements and provides high-quality EVA foam sheets. For example, Ideastep is a reputable supplier known for offering EVA foam sheets that are ideal for precision cutting and shaping. Evaluate potential suppliers based on their capabilities, experience, support, and pricing to find the best fit for your needs.

Conclusion

Choosing the right EVA foam sheet supplier for precision cutting and shaping involves understanding your requirements, assessing supplier capabilities, considering experience and reputation, evaluating support, and comparing costs. By following these guidelines, you can ensure that you partner with a supplier who delivers outstanding quality and precision for your projects. Consider working with trusted suppliers like Ideastep to meet your specific needs.

FAQ

- How do I determine my EVA foam sheet precision requirements?

Determine the specific needs of your project, such as material specifications and the degree of precision needed for cutting and shaping. - What should I look for in a supplier’s cutting technology?

Ensure the supplier uses advanced cutting technologies like CNC machines or laser cutters for high precision in cutting and shaping. - How important is supplier experience in choosing the right EVA foam supplier?

Experience is essential as it indicates the supplier’s ability to effectively handle precision tasks and understand industry nuances. - What role does customer service play in choosing a supplier?

Effective communication helps ensure that your requirements are met, and good customer service ensures prompt responses to questions and issues. - How can I determine a supplier’s cost-effectiveness?

Consider pricing and terms among suppliers, taking into account both the cost of materials and any additional charges for precision services.