Introduction

EVA foam stands for ethylene vinyl acetate foam, a versatile product used in many applications, from footwear to packaging. Ensuring that these products comply with the set market regulations has been paramount in their safety, functionality, and access. This paper addresses how best to ensure compliance of EVA products with key regulations, key recognized standards, best practice compliance approaches, and some of the pitfalls and areas that trip up suppliers the most.

1. Understanding EVA Foam and Regulations

What is EVA Foam?

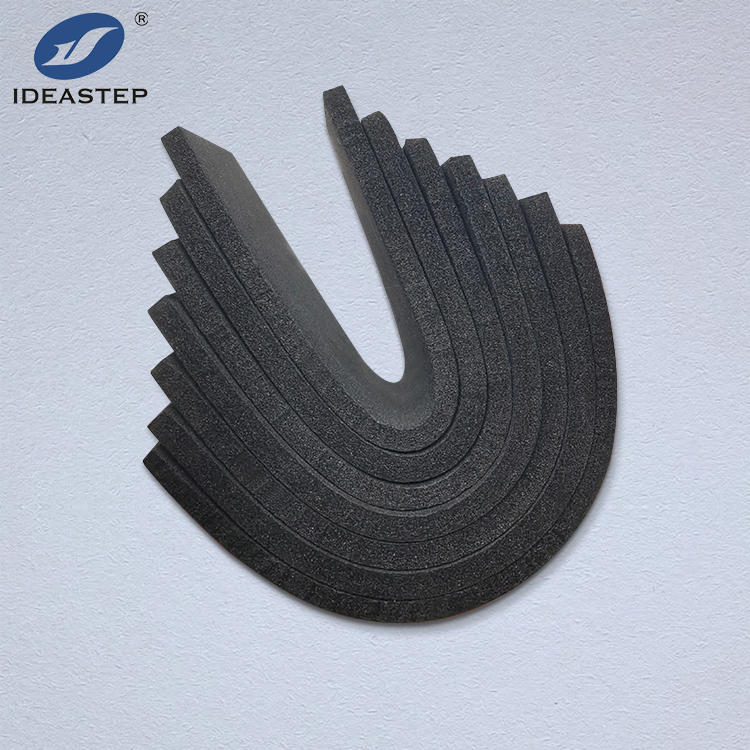

The EVA foam is extremely lightweight, flexible, and has excellent cushioning properties. As a result, this material has many wide applications in sport, footwear, packaging, among other industries. Knowing its characteristics is going to make it helpful to understand how best to assess compliance needs.

Why Compliance Matters

Compliance with regulations ensures that the products pose no harm to consumers or the environment. Generally speaking, regulations cover not only safety standards related to issues such as fire resistance and toxicity but also requirements about recyclability and substance restrictions for environmental concerns. Legal complications, product recalls, and brand reputation losses due to non-compliances are serious concerns one should be worried about.

2. Major Regulations Applying to EVA Foam Products

Safety Standards

The regulations regarding safety issues of many industries are also different. For example, EVA foam used in children’s toys should conform to the strict standards set by nontoxicity and fire-resistance analyses. Whereas, in footwear, it may be a matter of durability and comfort. All these details must be fully understood for conformance.

Environmental Regulations

With growing concern for the environment, regulations may also include the use of recyclable or biodegradable materials. More than this, it will be necessary to restrict hazardous substances like phthalates and heavy metals. Ensuring that EVA foam products meet these standards will avoid regulatory obstacles and improve product acceptability.

3. Steps to Ensure Compliance

Research and Identify Applicable Regulations

Do some research on the applicable regulations on your product and region. Because different regions have different standards, it will be important to fully understand the local and international regulations as ways to ensure compliance.

Material Sourcing and Testing

Suppliers are chosen who can provide EVA foam material that actually meets the stipulated regulations. Extensive testing should be conducted to ensure the foam actually meets the safety and environmental standards. This may involve the testing of the chemical content, flammability, and other properties.

Documentation and Certification

Maintain all records, including safety data sheets and test reports. Obtain all necessary certification from reputed bodies such as ASTM or ISO. This documentation will not only complement compliance but also build faith in customers and regulators.

4. Quality Control

Quality Assurance

Establish good internal quality control mechanisms to check for compliance issues in the production process. Regular audits and inspections will help identify any potential problems.

Training and Awareness

Train your staff about the general requirements of compliance and keep them informed on the changes occurring to regulations. Regular training will see that any person who contributes to the production stage gets equipped to understand and follow compliance rules.

5. Common Compliance Challenges and Solutions

Complexity of Regulations

The nature of regulatory necessities may be intricate with sometimes contradictory elements. Consult with experts or consultants on compliance for successful navigation.

Cost Issues

It can be tricky to balance these kinds of compliance costs against the price of your product. Consider compliance costs against the implications of compliance and figure out how best to incorporate that cost into your product development process while not affecting quality.

6. Conclusion

Regulatory compliance for EVA foam products is critical from a safety, marketing, and legal standpoint. If the concerned standards are well known, the implementation of effective quality control systems, and being informed with regard to changes in regulations, a way can successfully be ensured for compliance.

Frequently Asked Questions

What are the most common regulations for EVA foam products?

Common regulations include safety standards for non-toxicity and fire resistance, and environmental standards for recyclability and hazardous substance restrictions.

How can I verify if my EVA foam supplier meets regulatory standards?

Request documentation such as safety data sheets and test reports from your supplier. Ensure they have certifications from recognized regulatory bodies.

What steps should I take if my EVA foam products fail compliance tests?

Review the test results to identify the issues, adjust your materials or processes as needed, and retest to ensure compliance. Work with your supplier to address any problems.

How often should I review and update my compliance processes?

Regularly review and update your compliance processes, especially when regulations change or new standards are introduced. Annual reviews or following significant regulatory updates are good practices.