How to Ensure EVA Foam Sheets Have High Tear Strength

When used in applications where durability and resistance to abrasion are crucial, EVA panels must have sufficient tear strength. EVA (ethylene vinyl acetate) foam is popular for its flexibility, shock absorption, and versatility. However, in order to achieve maximum tear strength, EVA foam must be carefully selected, processed, and tested. We’ll go over the fundamental steps you need to take to increase your EVA panels’ tear strength in this guide.

Understanding EVA Foam’s Tear Strength

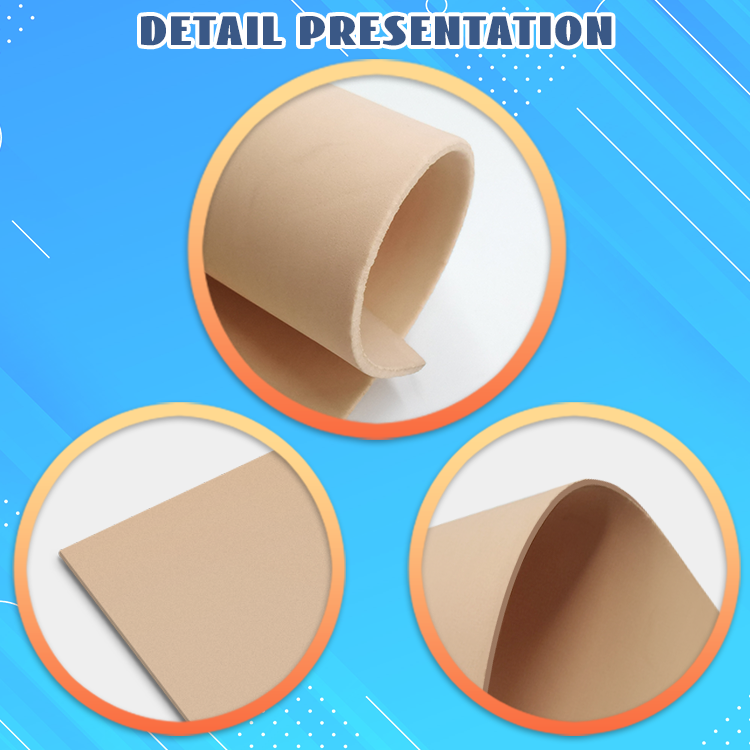

Tear strength is the capacity of a material to resist tearing when subjected to pressure. EVA foam sheets used as padding, cushioning, and protective coverings must have a high tear strength because the foam can be stressed and strained. The tear resistance of EVA foam reduces the likelihood of cracking and breaking over time.

Numerous factors influence EVA foam sheet’s tear strength. The tear strength of EVA foam sheet is influenced by the formulation of the foam, the manufacturing procedure, and the final quality control. The following aspects are examined:

1. Material Formulation

The manufacturing process determines EVA foam’s tear strength. Methods of processing, the type and concentration of additives, and the ratio of ethylene to vinyl acetate all have an impact on the foam’s final properties.

- Ratio of Ethylene to Vinyl Acetate: The amount of ethylene in the foam generally raises its flexibility and durability, while a higher vinyl acetate content increases its stiffness and tear resistance. Proper balance is necessary to attain the desired tear strength.

- Additives: By adding fillers and bonding agents, EVA foam can have improved mechanical properties. Cross-linking agents, which create a network of bonds, enhance the foam’s strength and longevity.

2. Manufacturing Process

The tear strength of EVA foam sheets is significantly influenced by the manufacturing process. The primary stages of the production process include:

- Extrusion and Molding: During the extrusion or molding process, proper adjustments to temperature, pressure, and cooling rates are required. Variations in these parameters can affect the foam’s tear strength.

- Foam Density: Higher density EVA foam generally offers better tear strength. Although lighter, lower density foam may not be as durable. Select the appropriate density based on your application requirements.

3. Quality Control and Testing

EVA foam sheets must pass standards for tear strength through quality control and testing. Make use of the following methods:

- Standardized Testing: Utilize industry-standard tear strength tests like ASTM D624 for your assessments. This test measures the foam’s resistance to tearing.

- Sample Inspection: Regularly examine foam samples from different production batches to identify variations in tear strength. Accurate quality checks help maintain high standards and prevent issues with the final product.

Best Practices for Increasing EVA Foam Sheets’ Tear Strength

The following best practices should be followed to increase EVA foam sheets’ tear strength:

1. Choose High-Quality Raw Materials

Select raw materials of high quality that are designed to enhance tear strength. Choose a supplier like Ideastep, which is known for strict quality control and advanced manufacturing, and look for one that offers consistent, dependable materials.

2. Optimize Production Parameters

Work with your production team to optimize extrusion or molding parameters. Control temperature, pressure, and cooling rates within acceptable limits to ensure uniform tear strength throughout the foam sheet.

3. Implement Robust Quality Control

Establish strong quality control procedures, including regular testing and inspection of foam sheets. Use standardized test methods to measure tear strength and compare results to predetermined standards.

4. Invest in Advanced Technology

Invest in cutting-edge manufacturing technology for precise control. Modern equipment with accurate temperature and pressure settings can significantly improve the tear strength of EVA foam sheets.

5. Proper Handling and Storage

Maintain tear strength by properly handling and storing EVA foam panels. Store the foam in an environment where it is protected from moisture and temperature fluctuations. Implement proper storage practices to ensure the foam’s durability and performance.

Conclusion

To ensure EVA foam sheets have high tear strength, it is crucial to adopt a comprehensive strategy that includes selecting appropriate material formulations, optimizing production processes, implementing quality control, and investing in advanced technologies. By focusing on these key aspects, you can enhance the stability and performance of EVA foam in various applications, ensuring that it meets the highest quality and reliability standards.

FAQ

Q: What factors influence EVA foam’s tear strength?

A: The production process (extrusion or molding methods, foam density), the material formulation (ratio of ethylene to vinyl acetate and additives), and quality control procedures (testing and sample inspection) all affect EVA foam’s tear strength.

Q: How can the tear strength of an EVA foam sheet be measured?

A: Standard methods, such as ASTM D624, can be used to measure tear strength. This test measures the foam’s resistance to tearing and provides valuable data about its performance.

Q: How can a supplier guarantee that the EVA foam it provides is tear-resistant?

A: Choose suppliers with high-quality raw materials and a strong production track record. Companies like Ideastep utilize advanced manufacturing techniques and stringent quality control to ensure high tear strength in their foam products.