Quality in EVA material is very critical for better performance and longevity for applications, ranging from footwear to automotive parts. This paper examines some of the main strategies and best practices that will ensure that quality standards are guaranteed during EVA material production. Companies manufacturing EVA materials can improve the quality of the products by paying extra attention to the selection of raw materials, manufacturing processes, and quality control.

1. Understanding EVA Material

What is EVA Material?

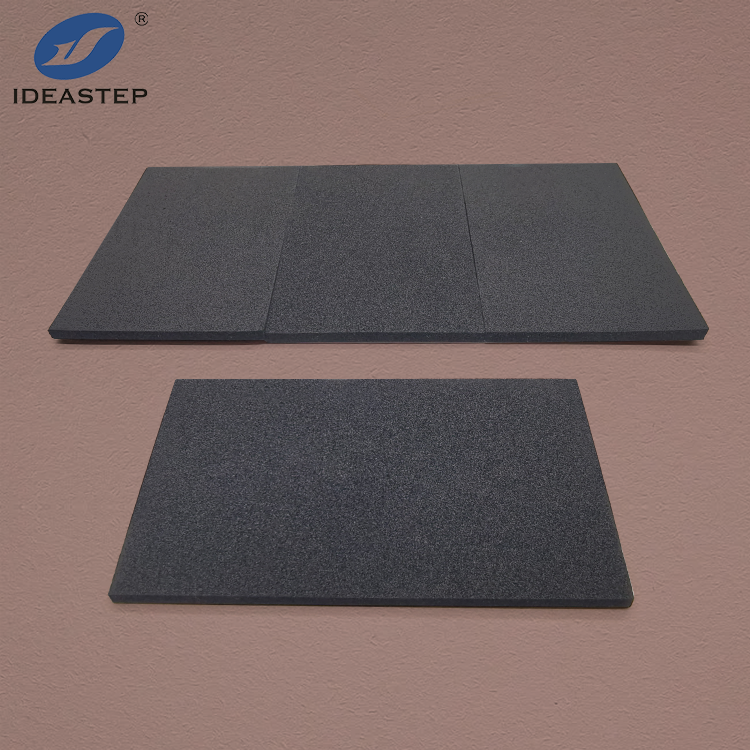

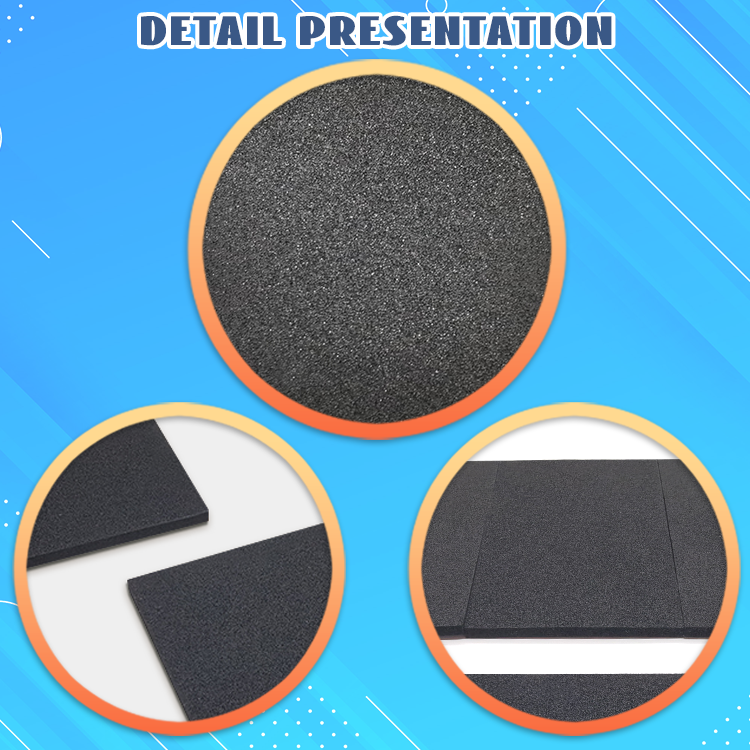

EVA, or Ethylene Vinyl Acetate, is a flexible elastomer with applications in cushioning and the absorption of shock for a wide range. Its properties make it very useful in diverse fields such as footwear and automotive.

Importance of Quality in EVA Production

Quality directly affects performance and service life. High-quality EVA commands better durability, flexibility, and consumer satisfaction.

2. Factors That Influence the Quality of EVA Material

Raw Material Selection

Selection of raw materials is the basis of producing a quality EVA. It requires good suppliers who must be accompanied by a proper inspection process to ensure that the best material provides the best result.

Manufacturing Processes

EVA is manufactured through various techniques like extrusion and molding. Due care in the processes will go a long way to giving the product consistency and quality.

Quality Control Measures

It will, therefore, be ensured that only high-quality EVA finds its way to the market through rigorous quality control, in-depth testing, and inspections.

3. Best Practices to Ensure Quality Production of EVA

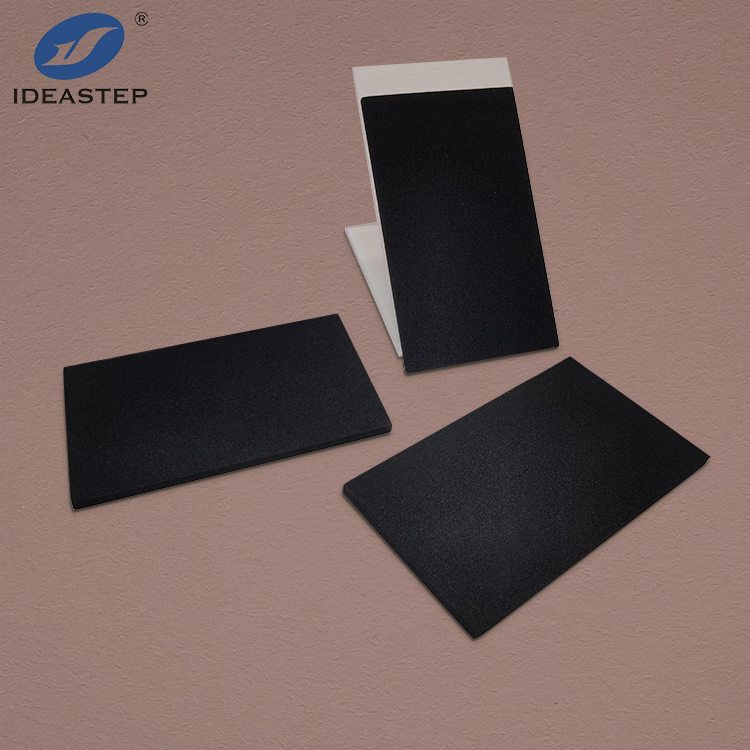

Material Handling and Storage

It is important to take good care of handling and storing EVA materials so that contamination or degradation does not take place. Material integrity may be maintained by following best practices for storage conditions.

Process Optimization

Temperature and pressure control in molding are among the production processes which, if optimized, can raise the quality of EVA products.

Employee Training

The training of employees concerning best practices and quality standards ensures that even on the lowest levels of the production process, quality is maintained.

4. Common Challenges and Solutions

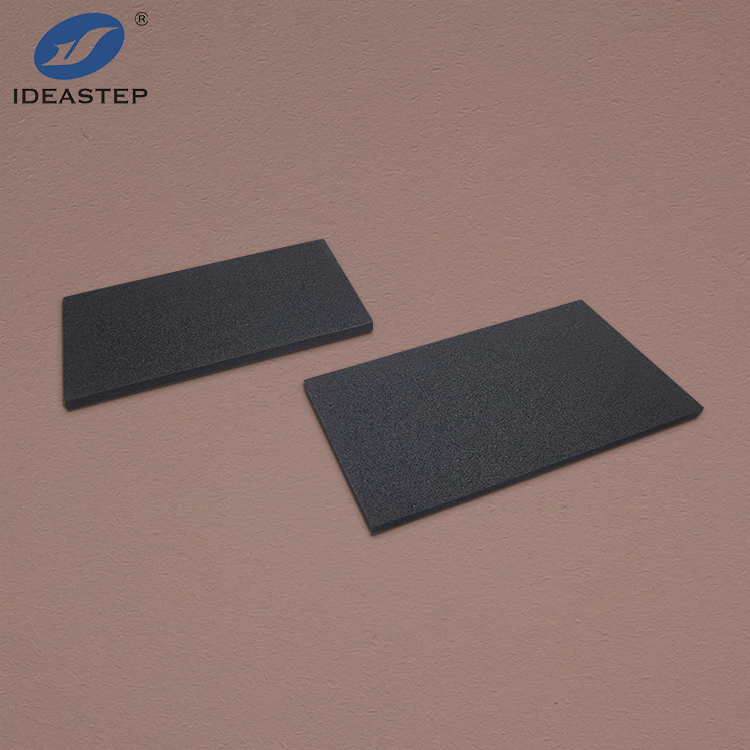

Material Properties Consistency

Keeping the properties of the materials consistent is quite a challenge. Strict quality control and regularly scheduled equipment maintenance can help control the situation.

Dealing with Defects

Defects are a result of the following. The most common types of defects are identified, and processes are improved to minimize their frequency.

5. Success Story of Quality EVA Production: Case Study

One of the best success stories about the production of EVA is regarding a company which improved the quality of their products by strictly enforcing quality control measures and optimizing its manufacturing process. This case represents significant dividends due to the proper implementation of best practice.

6. Conclusion

The quality of production of EVA material should be high, which is a factor not only of proper selection of raw materials but also their proper treatment, right process conditions in manufacturing, and generally dealing with quality control. It helps the manufacturer ensure good performance and durability of their EVA products.

7. FAQs

What are the key factors in EVA material quality assurance?

Raw material quality, processes of production, and quality control measures remain the prime considerations.

How can defects be minimized in the EVA material?

Apply strict quality control and optimization techniques for processes.

Why is training of employees so important in the production of EVA material?

Proper training is very necessary for any company to stick to quality standards and to improve its production result.

What are the normal problems that exist in EVA production?

Challenges that exist include consistency and defect management, which is improved through best practice.