Safety considerations of EVA blocks in manufacturing are very important to ensure a safe and productive environment. EVA blocks are manufactured from the material Ethylene Vinyl Acetate and enjoy great demand due to their flexibility, durability, and cost-effectiveness. However, like all other materials, EVA blocks also have some safety concerns. This article discusses crucial issues regarding the safety of the EVA block, including their chemical safety, physical safety, and environmental influences.

Understanding EVA Blocks

What are EVA Blocks?

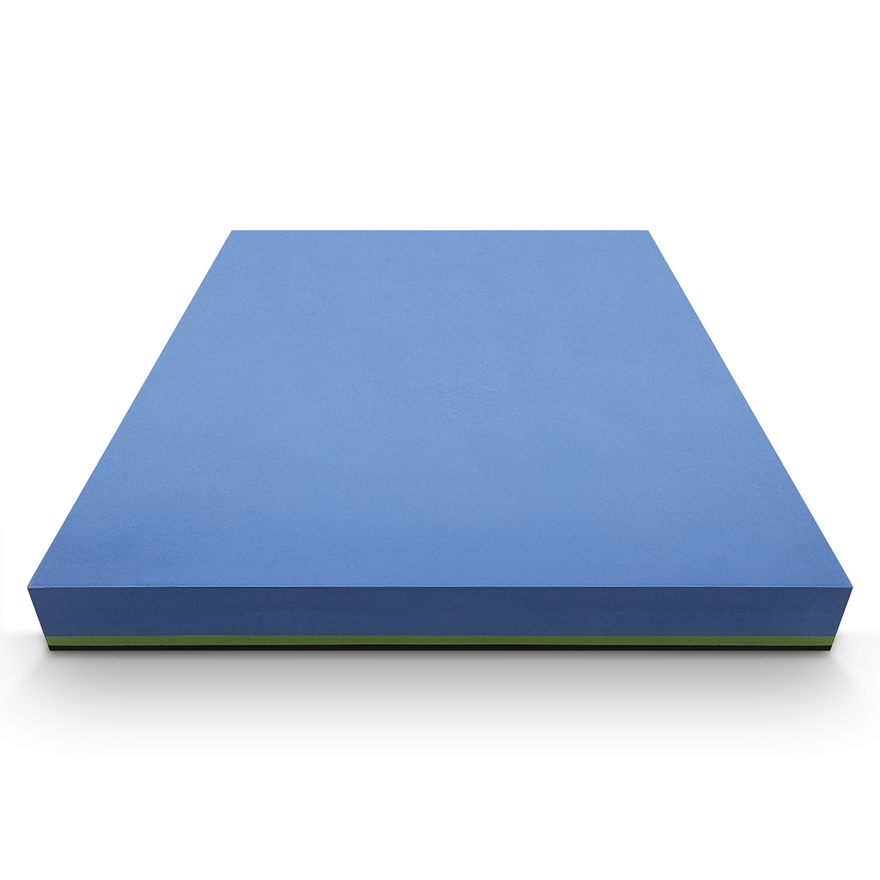

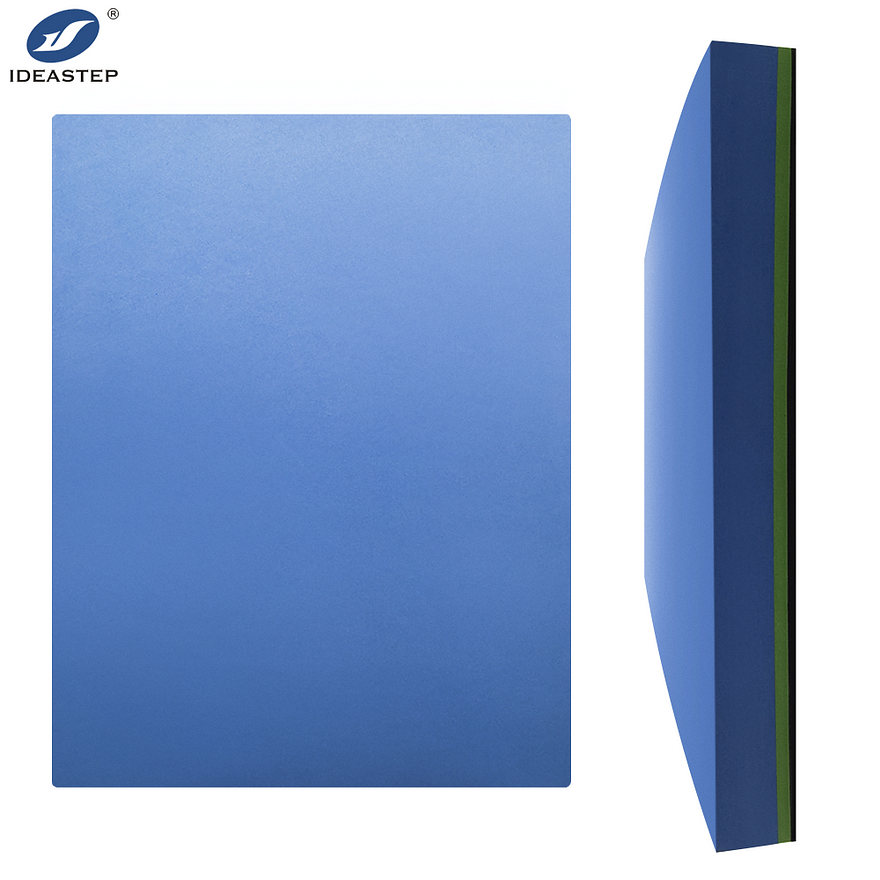

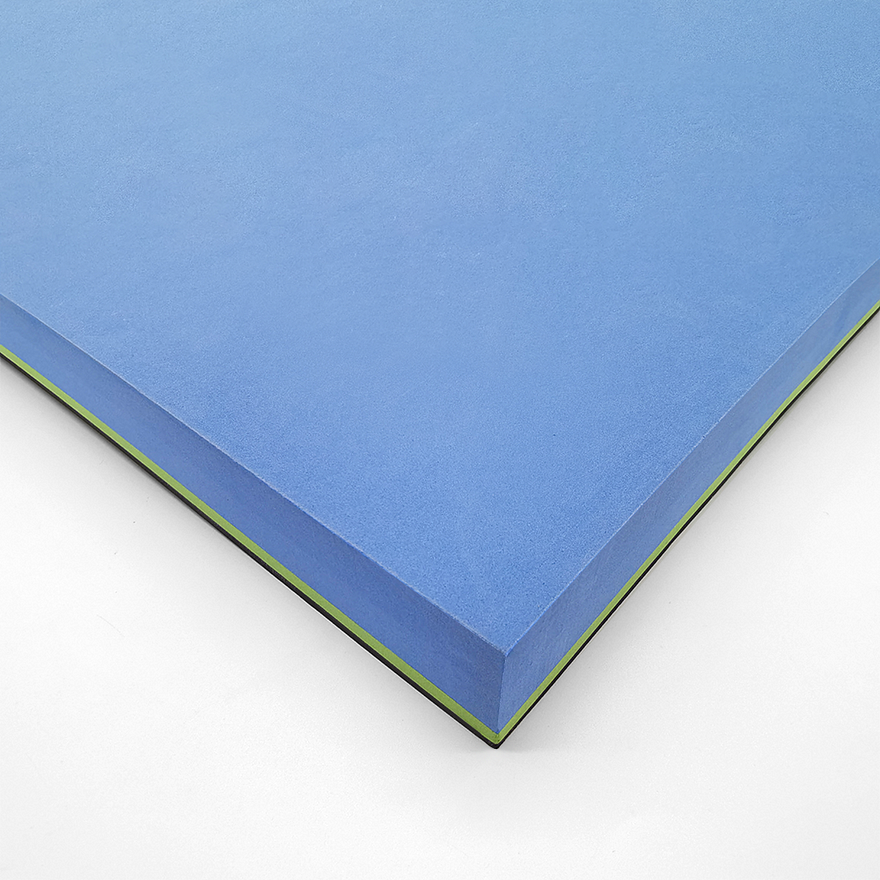

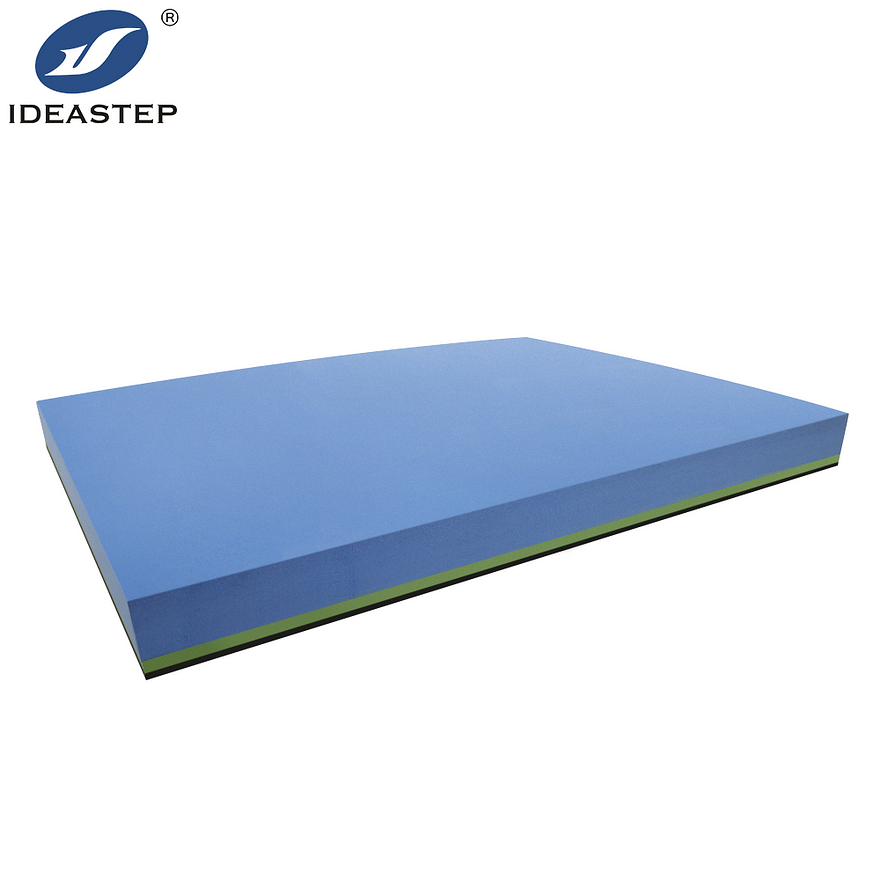

EVA blocks are a manufactured product from Ethylene Vinyl Acetate—a material capable of multiple uses, flexible, and with shock-absorbing properties. EVA can be used in several applications: cushioning, padding, and insulation. These EVA blocks are valued for their light weight and strength; hence, they will be suitable for many industries.

Why Safety Matters

Safety is the most critical issue concerning EVA blocks, given that these blocks prevent impending hazards that are likely to affect workers and the environment. Proper handling in conjunction with recommendations of appropriate safety standards averts accidents and maintains production quality.

Safety Concerns with EVA Blocks

Chemical Safety

Generally, blocks of EVA are not harmful; poor handling may result in exposure to dangerous chemicals. The safety data sheets which outline the chemical properties and safety precautions should be followed. Employ appropriate personal protective equipment and adequate ventilation during the use of the EVA blocks to minimize risks to your health.

Physical Safety

Handling and cutting EVA blocks can lead to physical hazards. Sharp tools and heavy blocks might cause cuts or strain injuries. As such, protective gloves and cut-resistant mats will be helpful in reducing the physical hazards involved in handling EVA blocks. In addition, employees should be trained on safe material handling since this would minimize accidents at workplaces.

Environmental Safety

EVA blocks contribute to environmental pollution if not disposed of appropriately. They are subject to recycling, according to local legislation, in order to reduce environmental hazards. A waste management plan institutes measures that will make sure that there is environmentally responsible handling of EVA blocks during and after production.

Safety Consideration in the Manufacture of EVA Blocks

Material Safety Data Sheets (MSDS)

MSDS supplies critical information on safe handling and storing, and on emergency procedure for EVA blocks. Ensure that all employees have access to and understand the MSDS relevant to the EVA blocks used in your manufacturing process.

Safe Handling Procedures

Safe storage and handling of EVA blocks are very important regarding safety. The blocks of EVA should be stored in a dry, well-ventilated area to avoid deterioration. Proper lifting techniques shall be followed with appropriate equipment to avoid injury during handling.

Equipment Safety

Ensure that all machinery utilized for the processing of EVA blocks is kept safe and operated safely. Regular safety inspections and maintenance checks will pave the way to preventing accidents of equipment origins. Training operators on safe use of machines and emergency procedures is key.

Compliance with Regulations and Standards

Industry Standards

It is important to note that EVA blocks need to follow industry standards in order to ensure safety. Understand regulations, such as ISO standards or any others related to manufacturing EVA blocks. Compliance with these standards will certainly ensure that the product is safe and reliable.

Testing and Certification

Testing and certification ensure that EVA blocks meet the required standards on safety and quality. Ensure that necessary certifications are from recognized organizations, and regular tests are conducted to prove that blocks fall within the parameters of necessary safety.

Best Manufacturing Practices to Ensure Safety

Training and Education

Regular training of employees on safety procedures and handling is essential. Supplement training programs with themes on how to use EVA blocks without causing an injury and response in the case of an emergency. Well-trained employees can handle situations positively and effectively that may involve safety concerns.

Emergency Procedures

Elaborate appropriate emergency procedures for handling accidents or spills of EVA blocks, and let every employee know. Routine drills are necessary to cope with the emergency.

Case Studies and Real-World Examples

Successful Safety Implementations

Various organizations have implemented the elements of safety over EVA blocks. These implementations result in improved workplace safety and also reduced incidents. A leading EVA block manufacturing company integrated proper safety training systems and routine maintenance of equipment. These two initiatives reduced workplace injuries considerably in their organization.

Common Safety Issues and Solutions

In EVA block production, one will commonly come across chemical contact and accidents caused by equipment. Practical solutions include the use of appropriate PPE, frequent safety auditing, and following principles of compliance with safety standards.

Frequently Asked Questions

What are the cardinal points of safety one has to observe when handling EVA blocks?

The main issues are chemical hazards, physical injury due to handling and cutting, and environmental impact. These would be appropriately handled by proper training, use of PPE, and waste management practices.

How can I ensure my EVA blocks are up to safety standards?

Verify conformance to appropriate industrial standards by checking for the relevant certification and testing. Ensure that the safety data sheets are available and that all the safety procedures are followed to the letter.

What protective equipment is suggested when dealing with EVA blocks?

The commonly needed protective equipment includes gloves, safety glasses, and cut-resistant mats. Employ the correct equipment and tools for handling and cutting EVA blocks to prevent risks and hazards.

How to dispose of or recycle EVA blocks safely?

EVA waste management in terms of disposal and recycling follows the set guidelines in your area. You will need a waste management plan for your EVA blocks from the time of production to its total disposal.

Sharing from the EVA Block Manufacturing Experience

Having worked with EVA blocks in manufacturing, I can attest that safety is always a prime concern. Implementing strict handling procedures and investment in employee training brought down the incidences of safety breaches and greatly improved safety standards overall. An investment in safety has translated to higher quality and safer work sites. We have been in a position to guarantee the efficiency and safety of the EVA block through full compliance with safety standards and regular reviews of practices.