1. Introduction

EVA blocks are very versatile and can be found in many industries, considering that they provide strength, flexibility, and cushioning. It only goes without saying that their optimization would significantly cut down on unnecessary waste and cost for any company that aspires to greater efficiency. This article will show how to optimize the usage of EVA blocks within your operations.

2. Understanding EVA Blocks

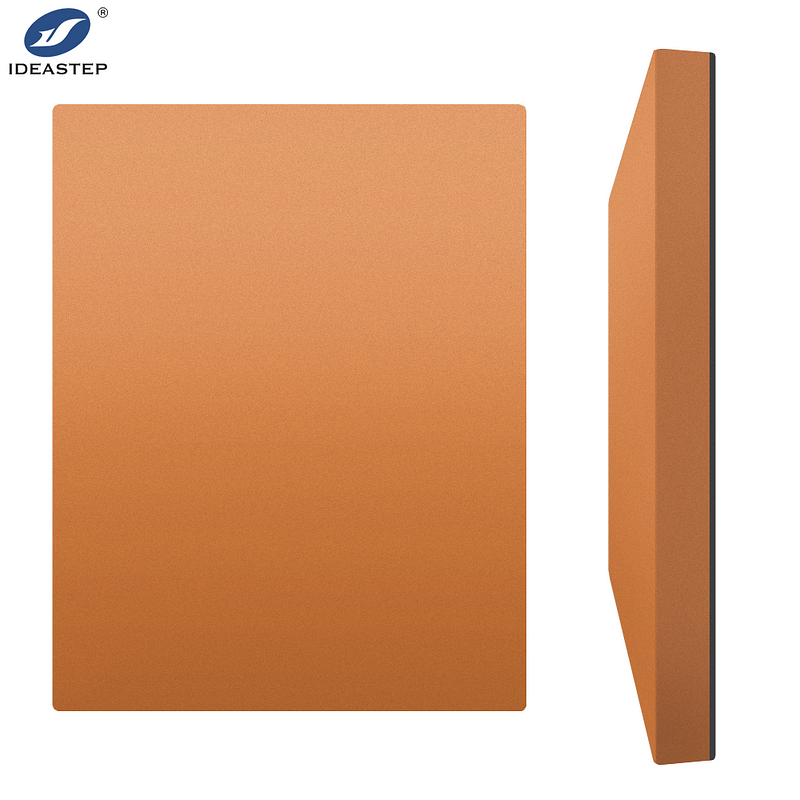

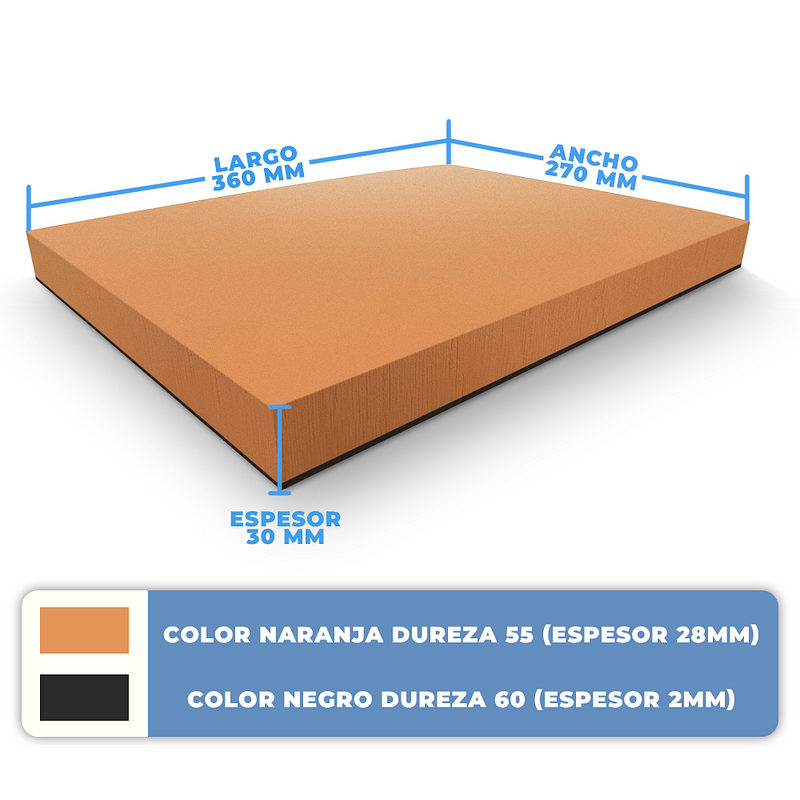

Definition and Composition

Ethylene Vinyl Acetate, shortly known as EVA blocks, comprise a mixture between ethylene and vinyl acetate. As such, they possess a peculiar combination of softness and resilience. They can be used for anything from padding to insulating.

General Characteristics

Among the general characteristics of EVA blocks are that they are lightweight, have very good shock absorption, and are flexible. These make them useful in applications needing cushioning and resistance to impact.

3. Assessing the Current Utilization of EVA Blocks

Present Uses

EVA blocks employed in manufacturing, construction, and even sports can serve for padding, insulation, and even noise dampening.

Locating the Inefficient Areas

Consider how EVA blocks are being utilized within your current process. Look for inefficiencies, such as very high waste or improper cuts. This will provide a clear indication of exactly where improvements may be made.

4. Best Practices for Optimizing EVA Block Usage

Proper Storage and Handling

Store EVA blocks in a cool, dry place and away from direct sunlight to prevent degradation. Proper handling will ensure that the blocks remain with their properties and can last longer, hence reducing the frequency of changing them.

Effective Cutting and Shaping

Use appropriate cutting tools to reduce waste and ensure EVA blocks are in shape according to specifications. Techniques involving laser cutters or automated machinery can increase the level of accuracy and efficiency.

Routine Maintenance and Inspection

Regularly inspect the EVA blocks for signs of wear that may be visible. Maintenance routines help identify and fix issues before they develop into major issues, ensuring effectiveness in their service areas.

5. Efficiency Using Technology

Advanced Cutting Tools

Investing in quality cutting tools can add to the accuracy in EVA block cuttings. Using machinery like CNC and water jets is able to provide sharper cuts, which creates less discrepancy and reduces waste.

Design and Layout Software

Lay out the design of the EVA blocks in your operation through design software. The software will optimize the use of material through giving you accurate measurements and reduce any possibility of discrepancies occurring in cutting and assembly.

6. Case Studies and Real-Life Examples

Industry: Manufacturing

Real-life: Advanced cutting tool usage coupled with optimized layout software saw 20% less EVA block waste; thus, making 20% of its production process more efficient.

Sector: Construction

Real-life: Good storage conditions and proper techniques for the accurate cutting of the EVA blocks saw the beginning of a construction company resulting in increasing safety measures on the site, contributing to waste reduction by 15%.

Sports and Recreation

A sports facility improved the utilization of EVA blocks by adopting technologies for cutting and design. This led to an advanced safety feature with a visible reduction in maintenance requirements.

7. Conclusion

Optimization in the usage of EVA blocks includes handling and energy-efficient cutting, apart from technology. The above changes, which involve the best practices, can improve the overall operations by waste reduction, leading to huge cost savings. Adapt yourself to such practices in order to get maximum out of EVA blocks for your needs.

8. Frequently Asked Questions

What are the main benefits of optimizing EVA block usage?

First, reducing the amount of used EVA blocks can lead to less waste, lower costs, and increased efficiency. With better quality, higher class, and better performance, EVA blocks are very helpful in certain applications.

How does technology apply to optimize EVA block usage?

Technology: Advanced cutting tools and design software can further enhance precision, reduce waste, and enhance overall efficiency in handling EVA blocks.

What are some common mistakes to avoid when using EVA blocks?

Common mistakes include inefficient practices concerning the storage of the materials, improper cutting practices, and neglect in regular maintenance. By avoiding these, the user will not only extend the life of the material but also yield the best result of the EVA block.

Can EVA blocks be recycled?

Yes, EVA blocks can be recyclable or reusable, and there is an EVA material recycling program for many industries. The reutilization of blocks for different purposes may also be a sustainable alternative.