Optimizing the performance of 50mm thick EVA foam sheets in high-stress environments involves understanding their properties, proper installation, and regular maintenance. This guide provides practical strategies to maximize their effectiveness and longevity in demanding applications.

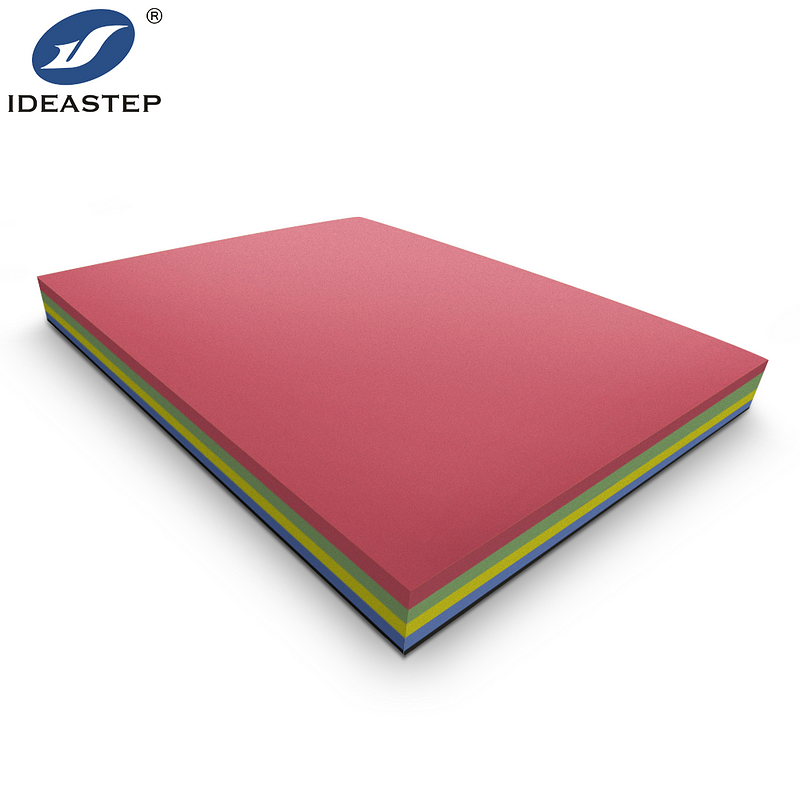

50mm thick EVA (Ethylene Vinyl Acetate) foam sheets are known for their exceptional cushioning, shock absorption, and durability. These properties make them ideal for high-stress environments where reliable performance is crucial. Whether used in sports equipment, flooring, or automotive applications, optimizing EVA foam sheets’ performance involves a combination of material understanding, correct installation practices, and ongoing maintenance. This guide offers practical tips to help you get the most out of your EVA foam sheets in demanding conditions.

1. Understand the Material Properties

To optimize EVA foam sheets’ performance, it’s essential to understand their material properties. Key characteristics include:

- Density: The density of EVA foam affects its cushioning and shock-absorbing capabilities. Higher density foam offers better support and durability, which is crucial in high-stress environments.

- Compression Resistance: EVA foam’s ability to return to its original shape after compression impacts its performance. Higher compression resistance ensures the foam maintains its cushioning properties over time.

- Temperature Stability: EVA foam’s performance can vary with temperature changes. Ensure that the foam is suitable for the temperature range of your application to avoid degradation.

Understanding these properties helps you select the right EVA foam sheets for your specific application and ensures optimal performance.

2. Proper Installation Techniques

Correct installation is vital for maximizing the performance of 50mm thick EVA foam sheets. Consider the following techniques:

- Surface Preparation: Ensure that the surface where the EVA foam sheets will be installed is clean, dry, and free of debris. Proper surface preparation enhances the adhesion and effectiveness of the foam.

- Cutting and Fitting: Use precise cutting tools to ensure that the foam sheets fit perfectly into the intended space. Gaps or misalignments can reduce the foam’s effectiveness and lead to premature wear.

- Adhesive Selection: Choose the right adhesive for bonding EVA foam sheets. Ensure that the adhesive is compatible with EVA material and suitable for the environment in which it will be used.

Proper installation techniques help ensure that the EVA foam sheets perform as intended and provide long-lasting benefits.

3. Regular Maintenance and Inspection

Maintaining and inspecting EVA foam sheets regularly is crucial for ensuring their continued performance. Follow these maintenance practices:

- Routine Inspections: Regularly inspect the foam sheets for signs of wear, damage, or degradation. Address any issues promptly to prevent further damage and maintain performance.

- Cleaning: Keep the foam sheets clean by using appropriate cleaning methods. Avoid harsh chemicals that can damage the material. Regular cleaning helps maintain the foam’s appearance and functionality.

- Replacement: Replace EVA foam sheets that show significant wear or damage. Regular replacement ensures that the foam continues to provide effective cushioning and support.

Regular maintenance and inspections help extend the lifespan of EVA foam sheets and ensure they continue to perform optimally in high-stress environments.

4. Environmental Considerations

Consider the environmental conditions where the EVA foam sheets will be used. Factors such as humidity, temperature, and exposure to chemicals can affect performance. Ensure that the EVA foam sheets are suitable for the specific environmental conditions to avoid premature deterioration.

5. Product Quality and Supplier Selection

Choose high-quality EVA foam sheets from reputable suppliers to ensure optimal performance. Evaluate suppliers based on their quality control measures, material specifications, and customer reviews. Working with reliable suppliers helps ensure that you receive EVA foam sheets that meet high standards of performance and durability.

Conclusion

Optimizing the performance of 50mm thick EVA foam sheets in high-stress environments involves understanding the material properties, following proper installation techniques, and conducting regular maintenance. By implementing these strategies, you can maximize the effectiveness and longevity of your EVA foam sheets, ensuring reliable performance in demanding applications.

FAQ

1. What factors should I consider when selecting EVA foam sheets for high-stress environments?

Consider factors such as density, compression resistance, and temperature stability. These properties will affect the foam’s performance and suitability for your application.

2. How can I ensure proper installation of EVA foam sheets?

Ensure proper surface preparation, use precise cutting tools, and select the right adhesive. Proper installation helps maintain the foam’s effectiveness and longevity.

3. What maintenance practices are essential for EVA foam sheets?

Regular inspections, cleaning, and timely replacement of worn or damaged foam sheets are essential for maintaining performance and extending the lifespan of the foam.