For thick, colorful rubber EVA sheets to perform at their best and be suitable for a variety of industrial applications, it is essential to select the appropriate thickness. This guide provides in-depth advice on how to select the appropriate thickness based on your particular requirements and the requirements of your industry.

How to Choose the Right Thickness for Your Industry’s Thick Colorful Rubber EVA Sheets

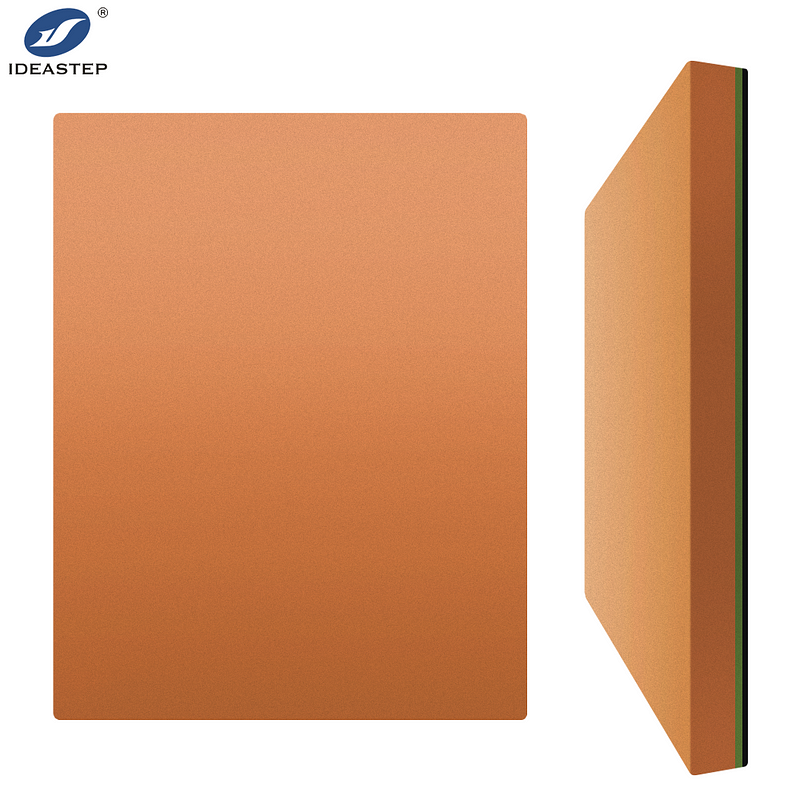

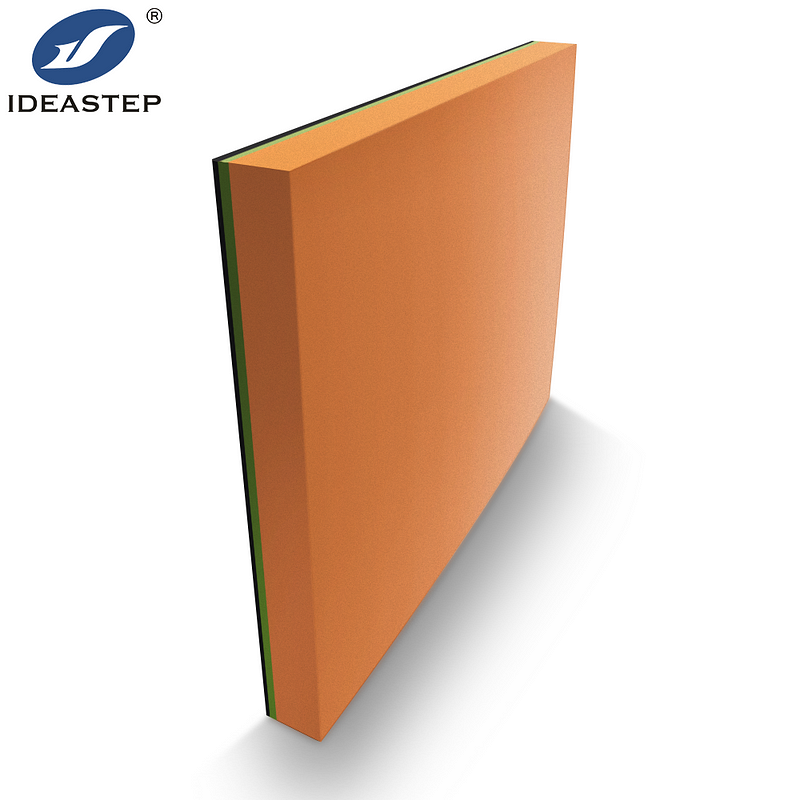

Thick rubber EVA (Ethylene Vinyl Acetate) sheets are used in a lot of different industries because they are durable, flexible, and come in a lot of different colors. Picking the right thickness is fundamental to guarantee that these sheets meet the exhibition models and necessities for various applications. This guide offers exhaustive counsel on choosing the right thickness for EVA sheets to expand their adequacy in your industry.

1. Grasping EVA Sheets and Their Applications

EVA sheets are esteemed for their padding properties, influence obstruction, and tasteful allure. Their thickness can essentially influence their exhibition in different applications like defensive stuff, deck, and bundling. Understanding the job of thickness according to your particular application is urgent for making an educated choice.

2. Factors Influencing Thickness Selection

The choice of thickness for EVA sheets is influenced by a number of factors, including the following:

- Application Necessities: Depending on the amount of cushioning or impact resistance that is required, different applications call for different thicknesses. For example, defensive stuff, for example, head protectors or knee cushions might require thicker sheets for better shock ingestion, while deck might require a harmony among thickness and adaptability.

- Effect and Shock Ingestion: EVA sheets that are thicker offer superior shock and impact absorption. This is especially important in applications like protective padding or sports equipment where high impact resistance is essential.

- Conformability and Flexibility: Thicker sheets might be not so much adaptable but rather more unbending, which can influence their capacity to adjust to various shapes and surfaces. Consider the expected adaptability for your application while picking the thickness.

- Longevity and Durability: Thicker EVA sheets commonly offer more noteworthy toughness and longer life expectancy, making them appropriate for high-traffic regions or weighty use applications. However, they may also be bulkier, which may have an effect on your product’s design and aesthetics.

- Costs to Consider: Thicker EVA sheets might be more costly than more slender ones. Offset the expense with the advantages given by the extra thickness to guarantee that it fits acceptable for you while meeting execution prerequisites.

3. Industry-Specific Considerations

The following industries have distinct requirements for the thickness of EVA sheet:

- Gear for Sports and Safety: For athletic gear, for example, boxing cushions or exercise mats, thicker EVA sheets are liked for improved shock retention and effect insurance. Pick a thickness that offers the vital padding without compromising adaptability.

- Flooring Arrangements: The thickness of flooring should strike a balance between durability and cushioning in applications like playground mats and industrial flooring. Choose a thickness that is easy to install and maintain while still providing adequate protection from falls and impacts.

- Packaging: For bundling arrangements, thickness prerequisites rely upon the degree of security required for the items. Thicker sheets give better assurance however might be less practical for lightweight things.

- Car and Aviation: In car and aviation businesses, thickness ought to be picked in light of the particular necessities for protection, influence opposition, and solidness. For components that require additional noise reduction or protection, thicker EVA sheets may be required.

4. Testing and Validation

Before choosing a thickness, thoroughly test and validate the EVA sheets to make sure they meet your performance needs:

- Tests on a Sample: Acquire tests of various thicknesses and test them under true circumstances to survey their presentation. This will assist you in selecting the thickness that best suits your requirements.

- Talk with Specialists: Draw in with industry specialists or providers to get suggestions in light of their experience and information. They can help you figure out which thickness is best for your particular application.

- Examine the Norms of the Industry: For your application, check to see if there are any industry standards or guidelines for EVA sheet thickness. Sticking to these principles can guarantee that your item meets quality and security necessities.

5. Picking the Right Provider

Choosing a trustworthy provider is critical for getting top notch EVA sheets with the ideal thickness. Ideastep, for example, offers an assortment of thick bright EVA sheets that can be modified to meet explicit industry necessities. Assess potential providers in light of their item quality, client assistance, and capacity to give the expected thickness.

Conclusion

If you want thick, colorful rubber EVA sheets to perform at their best in your industry’s applications, you must choose the right thickness. You can make an informed decision that improves your product’s effectiveness by taking into account things like application requirements, impact absorption, flexibility, durability, and cost. For custom-made EVA sheets of high quality, work with dependable vendors like Ideastep.

FAQ

- How do I choose the appropriate thickness for EVA sheets?

When choosing a thickness, think about the application requirements, impact absorption requirements, flexibility, durability, and cost. - What factors influence EVA sheet thickness selection?

Application requirements, impact resistance, adaptability, durability, and costs are important considerations. - Are EVA sheets that are thicker always better?

Thicker EVA sheets give better effect assimilation and toughness yet might be not so much adaptable but rather more exorbitant. Pick thickness in light of explicit application needs. - How can I determine which thicknesses of EVA sheet are appropriate?

Get tests, direct genuine testing, talk with specialists, and survey industry principles to evaluate the reasonableness of various thicknesses. - Where might I at any point find solid providers for EVA sheets?

Look for reputable suppliers like Ideastep that provide customizable, high-quality EVA sheets that meet the needs of your industry.