How to Use 50mm Thick EVA Foam Sheets for Industrial Applications

The versatility and durability needed from a material are provided by EVA foam sheets, making them one of the staples in various industrial applications. Out of all the thicknesses these are available in, the 50mm thick EVA foam sheet is excellent in numerous aspects of delivering sturdy performance under very demanding environments. In this article, we will definitely dig deep into what is the best way of using a 50mm thick EVA foam sheet in an industrial setup, the benefits, applications, and lastly best practices.

What is EVA Foam?

EVA foam is a closed-cell, lightweight foam material with the homogenous properties of shock absorption, flexibility, and being moisture and chemical resistant. The 50 mm thickness especially will be designed for application areas that require reasonably higher cushion and support. It would be offering great toughness in respect of impact, insulation, and durability, hence fitting diverse industrial applications.

Advantages of 50mm Thick EVA Foam Sheets

1. Increased Cushioning and Impact Absorption

The major advantage of using 50mm thick EVA foam sheets is that they have an optimum cushioning capacity. This thickness can give an excellent shock absorbency, hence appropriate where protection from impact is necessary. For instance, in machines and equipment, EVA foam may partly reduce vibrations and render some protection against sudden shocks.

2. Thermal Insulation

EVA foam sheets also exhibit excellent attributes of thermal insulation. Therefore, they are excellent to be used in controlled temperature places. Whether it is the pipe work, machinery insulation, or storage areas, this 50mm thickness will make sure that there is very minimal heat loss, and the temperature within the places is highly maintained.

3. Chemical Resistance

Most industrial environments are all about exposure to one chemical or another. Since EVA foam is chemically resistant, 50mm thick sheets withstand very harsh conditions without degradation. This makes them relevant in applications exposing the sheets to chemical processing and manufacturing industries where functional survivability under given chemical exposures is a factor.

Applications of 50mm Thick EVA Foam Sheets

1. Protective Padding and Cushioning

In industries where equipment or machinery is subjected to frequent handling, 50mm thick EVA foam sheets can be used as protection padding. They cushion parts during transit or in operation, reducing the risk of damage. For example, EVA foam sheets provide protection in the automotive and aerospace industries against vibrations and shocks that may affect sensitive components.

2. Construction Insulation

The EVA foam is used in construction projects, benefiting them both thermally and also acoustically due to its insulation properties. If 50mm thick EVA foam sheets are used as an insulating material of the walls, floors, or ceilings, they maintain comfortable temperatures and reduce noise. Hence, it assures energy efficiency and improved acoustic performance in buildings.

3. Custom Molding and Fabrication

The flexibility of EVA foam allows it to be molded and fabricated by design. 50mm thick EVA foam sheets can be cut, shaped, and molded in the manufacture and design of industrial designers and manufacturers according to various needs for making different parts and components. This flexibility of the material can be useful for creating prototypes, tooling, or bespoke solutions based on specific industrial needs.

Best Practices for Using 50mm Thick EVA Foam Sheets

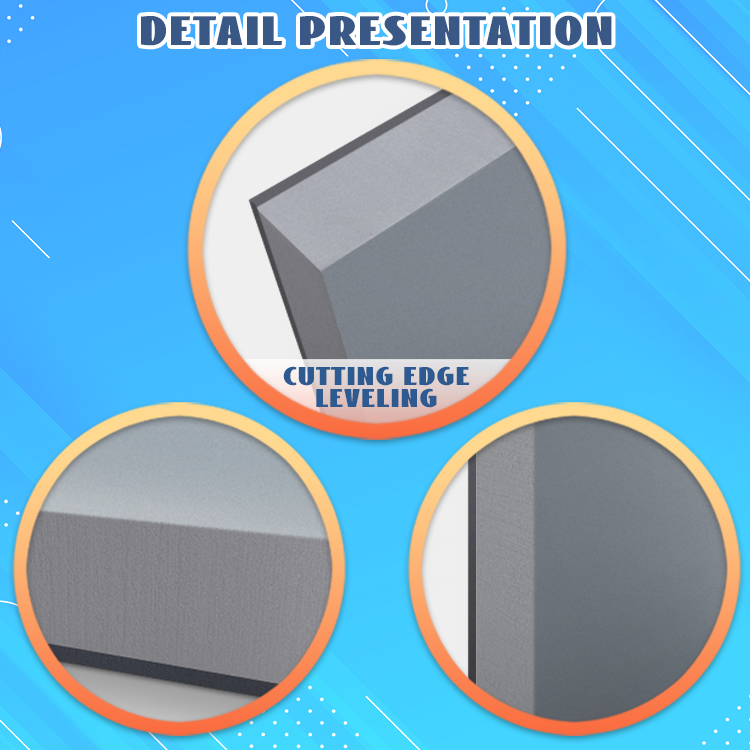

1. Proper Cutting and Shaping

Secured installation to give the best results, EVA foam sheets are to be cut accurately and with a perfect shape. Sharp tools or a CNC machine make accurate cuts that do not tear or lead to compression in the foam that could have an impact on performance. Measuring twice and cutting once can be very valuable in saving time and materials.

2. Secure Installation

When mounting EVA foam, whether for insulation or padding purposes, firmly affix EVA foam sheets in a way that they do not frequently move around. Apply proper adhesives or mounting techniques that easily secure the foams, for example, in heavy traffic or heavily vibrating areas.

3. Regular Maintenance

Inspect the EVA foam sheets periodically to ensure they are in good condition. Replace sections that look worn or damaged. Replacing sections will increase the life expectancy of the foam, while providing a continuing presence of the foam.

Frequently Asked Questions

Q: Is it possible to recycle EVA foam?

Ordinary EVA foam is not very recyclable, but there are some special recycling centers that can process it. Check local recycling centers or waste management services for disposal options.

Q: How does thickness affect the performance of EVA foam?

The thicker an EVA foam is, the better the cushioning and impact absorption, and the better the thermal insulation it gives. In case a big amount of protection and support was needed, the 50mm thickness is appropriated.

Q: Are there any limitations associated with the use of EVA foam in industrial settings?

While EVA foam is versatile in many ways, it may not be suitable for extremely high-temperature environments or under very heavy loads without additional support. Always consider the specific requirements of your application when selecting materials.

Conclusion

So many advantages are offered by the 50 mm EVA foam sheets due to many industrial needs, ranging from cushioning to thermal insulation. Its flexibility and toughness contribute to a great many applications in the automotive, aerospace, construction, and manufacturing areas. To derive the maximum benefit from EVA foam properties and to use it in your industrial application with maximum performance, consider the advantages and follow the guidelines.