Innovations in EVA block formulation are transforming the landscape of B2B manufacturing. This article explores the latest advancements in EVA block technology, including enhanced performance characteristics, sustainable practices, and customization options, offering valuable insights for manufacturers looking to stay ahead in a competitive market.

Innovations in EVA Block Formulation: Advancing Techniques for B2B Manufacturers

EVA (Ethylene Vinyl Acetate) blocks have long been integral to various industries due to their versatility and performance. Recent advancements in EVA block formulation are revolutionizing how these materials are used in B2B manufacturing. This article delves into the cutting-edge innovations in EVA block technology, highlighting how these advancements are driving improvements in performance, sustainability, and customization for manufacturers.

1. Enhanced Performance Characteristics

One of the most significant innovations in EVA block formulation is the enhancement of performance characteristics. Modern EVA blocks are engineered to offer superior mechanical properties, such as increased durability, flexibility, and resilience. Advances in polymer chemistry have led to the development of EVA formulations with optimized cell structures, which improve shock absorption and impact resistance. These advancements result in EVA blocks that are better suited for demanding applications, from high-performance sports equipment to robust industrial components.

2. Sustainable Formulation Practices

With growing environmental concerns, there has been a significant shift towards sustainable formulation practices in EVA block production. Manufacturers are increasingly adopting eco-friendly practices, such as incorporating recycled materials and reducing the carbon footprint of production processes. Innovations include the use of bio-based EVA formulations, which are derived from renewable resources, and advanced recycling techniques that convert used EVA products back into raw materials. These sustainable practices not only help reduce environmental impact but also appeal to environmentally conscious consumers and businesses.

3. Advanced Customization Techniques

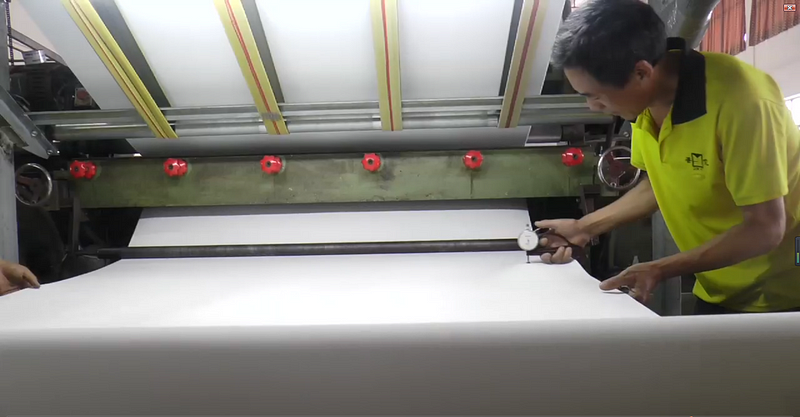

Customization is a key trend driving innovation in EVA block formulation. Advances in manufacturing technologies, such as precision molding and advanced extrusion processes, allow for greater control over the physical properties of EVA blocks. Manufacturers can now create blocks with specific densities, hardness levels, and colorations tailored to the unique requirements of different applications. This level of customization enables the production of EVA blocks for specialized uses, such as medical devices, aerospace components, and consumer goods, providing enhanced functionality and performance.

4. Improved Thermal and Chemical Resistance

Recent innovations have also focused on enhancing the thermal and chemical resistance of EVA blocks. New formulations are being developed to withstand extreme temperatures and exposure to various chemicals, expanding the range of applications for EVA blocks. These advancements are particularly beneficial for industries such as automotive and industrial manufacturing, where components must endure harsh conditions. Improved resistance properties ensure that EVA blocks maintain their integrity and performance even in demanding environments.

5. Smart EVA Blocks: Integration with Technology

The integration of technology with EVA blocks represents a groundbreaking innovation. Smart EVA blocks are equipped with embedded sensors and connectivity features that enable real-time monitoring and data collection. These smart blocks can be used in various applications, such as tracking wear and tear in industrial components or monitoring health metrics in medical devices. The incorporation of technology into EVA blocks opens up new possibilities for smart manufacturing and enhanced product functionality.

6. Enhancements in Manufacturing Efficiency

Advancements in EVA block formulation have also led to improvements in manufacturing efficiency. Innovations in production techniques, such as automation and process optimization, have reduced manufacturing time and costs. Enhanced quality control measures ensure consistent product performance and reduce waste. These improvements benefit B2B manufacturers by providing cost-effective solutions and faster turnaround times, ultimately leading to a more competitive edge in the market.

7. Future Directions in EVA Block Innovation

The future of EVA block formulation is poised for further innovation. Ongoing research and development are expected to focus on creating even more advanced materials with improved properties and functionalities. Areas of interest include the development of ultra-lightweight EVA blocks, enhanced bio-compatibility for medical applications, and further advancements in sustainability. Staying abreast of these trends will be crucial for B2B manufacturers looking to leverage the latest technologies and maintain a competitive advantage.

Conclusion

Innovations in EVA block formulation are transforming the landscape of B2B manufacturing, offering enhanced performance, sustainability, and customization options. From improved mechanical properties and sustainable practices to advanced customization techniques and integration with technology, these advancements are driving the evolution of EVA blocks. Manufacturers like Ideastep are at the forefront of these innovations, providing cutting-edge solutions that meet the evolving needs of various industries. Embracing these advancements will enable manufacturers to deliver high-quality products and maintain a competitive edge in the market.

FAQ

1. What are the benefits of enhanced performance characteristics in EVA blocks?

Enhanced performance characteristics in EVA blocks offer several benefits, including improved durability, flexibility, and impact resistance. These advancements make EVA blocks more suitable for demanding applications, such as sports equipment and industrial components, by providing better shock absorption and resistance to wear and tear.

2. How do sustainable formulation practices impact the EVA block industry?

Sustainable formulation practices impact the EVA block industry by reducing environmental impact and appealing to environmentally conscious consumers. The use of recycled materials, bio-based formulations, and advanced recycling techniques helps minimize the carbon footprint and promotes eco-friendly production processes.

3. What are smart EVA blocks and how do they benefit manufacturers?

Smart EVA blocks are equipped with embedded sensors and connectivity features that enable real-time monitoring and data collection. They benefit manufacturers by providing valuable insights into product performance, wear and tear, and other metrics, allowing for proactive maintenance and enhanced functionality in applications such as medical devices and industrial components.