In B2B transactions involving EVA (Ethylene Vinyl Acetate) material, adherence to key quality standards is crucial for ensuring the reliability and performance of the products. These standards cover various aspects, including material composition, physical properties, and manufacturing processes, to guarantee that the EVA material meets the specific requirements of different applications.

EVA (Ethylene Vinyl Acetate) is a widely used material in various industries, including footwear, packaging, and sports equipment. For B2B transactions, understanding and adhering to key quality standards is essential to ensure that the EVA material meets the desired performance and durability requirements. This article outlines the primary quality standards for EVA material in B2B transactions and their significance in ensuring product quality and consistency.

1. Material Composition

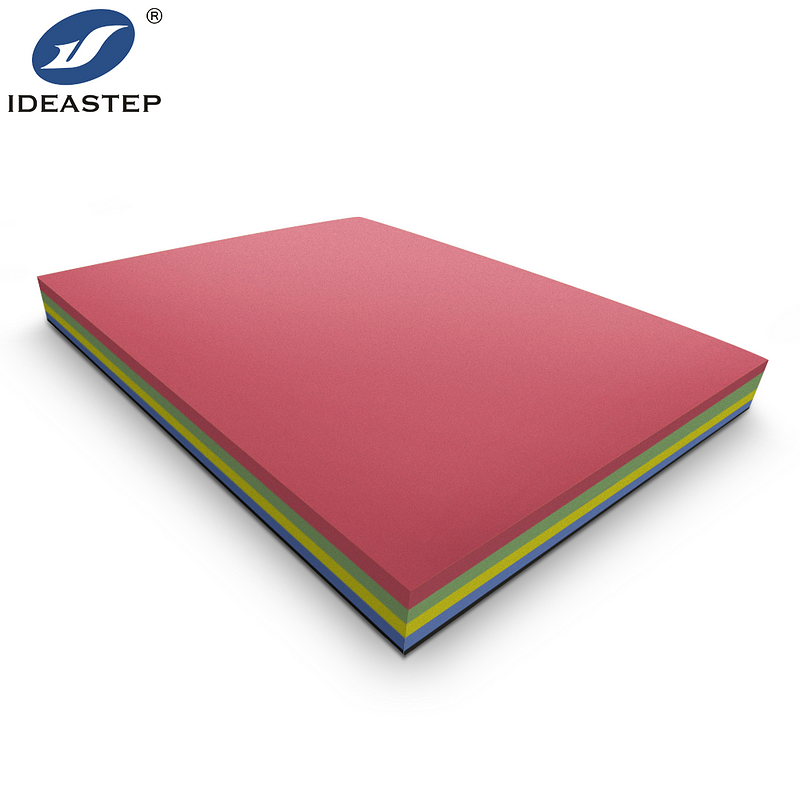

The composition of EVA material is a critical factor that affects its performance and suitability for different applications. Key quality standards specify the ratio of ethylene to vinyl acetate, which determines the material’s flexibility, elasticity, and impact resistance. The purity of the raw materials and the consistency of the blending process also play a significant role in achieving the desired material properties. Ensuring that the EVA material meets the specified composition standards helps prevent issues such as inconsistent performance or premature wear.

2. Physical Properties

Several physical properties of EVA material are subject to quality standards to ensure its suitability for specific uses. These properties include:

- Density: The density of EVA material affects its cushioning and impact absorption capabilities. Standards specify the acceptable density range for different applications, such as footwear or sports equipment.

- Tensile Strength: Tensile strength measures the material’s resistance to stretching or breaking under load. Quality standards define the minimum tensile strength required for EVA material to ensure durability and reliability.

- Elongation: Elongation refers to the material’s ability to stretch without breaking. Standards set limits on elongation to ensure that EVA material can withstand deformation and maintain its performance.

- Compression Set: Compression set measures how well the material recovers after being compressed. Quality standards specify acceptable levels of compression set to ensure that EVA material maintains its shape and performance over time.

3. Manufacturing Processes

Adherence to quality standards in the manufacturing process is essential to ensure the consistency and reliability of EVA material. Key aspects include:

- Polymerization: The polymerization process must be controlled to achieve the desired polymer properties. Standards ensure that the polymerization conditions are optimized to produce high-quality EVA material.

- Compounding: The compounding process involves mixing the EVA polymer with additives. Quality standards specify the types and amounts of additives used to ensure the material’s performance and safety.

- Extrusion and Molding: Extrusion and molding processes must be monitored to ensure that the EVA material is formed to the correct specifications. Standards define the acceptable parameters for extrusion and molding to prevent defects and ensure product consistency.

4. Testing and Certification

Testing and certification are crucial components of quality assurance for EVA material. Various tests are conducted to verify that the material meets the required standards, including:

- Performance Testing: Performance tests evaluate the material’s ability to meet specific requirements, such as cushioning or impact resistance. Certification bodies may conduct these tests to ensure compliance with industry standards.

- Safety Testing: Safety tests ensure that the EVA material does not contain harmful substances and meets environmental and health regulations. Certification may be required to confirm that the material is safe for use in products such as footwear or medical devices.

5. Supplier Certification and Documentation

When sourcing EVA material for B2B transactions, it is important to verify that suppliers are certified and provide appropriate documentation. Certifications from recognized industry bodies can provide assurance of the material’s quality and compliance with standards. Documentation such as certificates of conformity, test reports, and material safety data sheets (MSDS) should be reviewed to ensure that the EVA material meets the required specifications and standards.

Conclusion

Adhering to key quality standards for EVA material in B2B transactions is essential for ensuring that the material meets performance, durability, and safety requirements. By understanding and applying these standards, businesses can make informed decisions when sourcing EVA material and ensure that their products are of high quality and consistent. Quality control measures, testing, and supplier certification play a crucial role in maintaining the reliability and effectiveness of EVA materials across various applications.

FAQ

1. What is the importance of material composition in EVA quality standards?

The material composition, including the ratio of ethylene to vinyl acetate, affects the EVA material’s flexibility, elasticity, and impact resistance. Adhering to composition standards ensures consistent performance and prevents issues such as premature wear.

2. What physical properties are monitored in EVA material quality standards?

Physical properties such as density, tensile strength, elongation, and compression set are monitored to ensure that the EVA material meets specific performance and durability requirements.

3. Why is supplier certification important in B2B transactions for EVA material?

Supplier certification provides assurance that the EVA material meets industry standards and specifications. Certification and proper documentation help verify the material’s quality and compliance with safety and performance requirements.