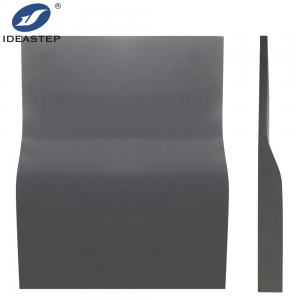

CAD/CAM Blockers / EVA Foam Block For Milling

Description

| code | size | hardness | Material | color |

| EM1 | 115*37cm*(1-4)mm | Green A50-55 (1-4)mm | EVA | green |

| EM2 | 115*37cm*(1-4)mm | Blue A50-55 (1-4)mm | EVA | blue |

| EM3 | 115*37cm*(1-4)mm | White A50-55 (1-4)mm | EVA | white |

| EM4 | 115*37cm*(1-4)mm | Red A50-55 (1-4)mm | EVA | Red |

CAD/CAM milling block/EVA foam block:

EVAFoam block is a foam material made from ethylene vinyl acetate copolymer (EVA) and has many excellent properties. It has the advantages of light weight, softness, heat preservation, shock absorption and buffering, sound insulation and cold protection, anti-aging, low water absorption, flame retardant, antiseptic, non-toxic and tasteless, non-mildew, non-moth-eaten, etc. Therefore, EVA foam blocks are widely used in various fields such as building insulation, packaging materials, sound insulation materials, shock absorption materials, insoles, etc.

EVA is an ethylene vinyl acetate copolymer with the following properties:

1. Excellent elasticity and flexibility: EVA material has high elasticity and flexibility, which can effectively alleviate external impact and compression and protect items from damage.

2. Good wear resistance and chemical resistance: EVA material has excellent wear resistance and chemical resistance, and can effectively resist external friction and chemical corrosion, maintaining the integrity and stability of the material.

3. Excellent weather resistance: EVA material has excellent weather resistance and can maintain stability and performance under different climate conditions.

4. Easy to process: EVA materials are easy to process and shape, and different shapes and sizes can be achieved through different processing methods.

In addition, EVA materials are non-toxic, odorless, and transparent, and are widely used in the manufacturing of wire and cable materials, films and other molded products and mixtures, automotive industry components, adhesives, coatings and other fields.

PS:Milling refers to the use of rotating multi-edged cutting tools to cut workpieces. It is an efficient processing method. When working, the tool rotates (as the main movement) and the workpiece moves (as the feed movement). The workpiece can also be fixed, but at this time the rotating tool must also move (complete both the main movement and the feed movement). to sports). feed movement).