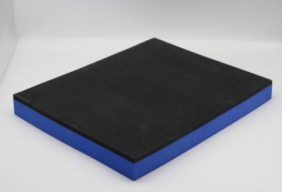

multi-layer Laminated Eva Closed Cell Foam Board

| Place of Origin | China |

| Brand Name | Ideastep |

| Model Number | 42# |

| Material | EVA |

| Thickness | As per requirement |

| Size | Customized Size, Customized Size |

| Color | Customer Requirement |

| MOQ | 2 pcs |

| Certificate | BSCI |

| Application | High density EVA material |

| Feature | A EVA Blocks laminated by glue in different functional layers |

| Usage | For CAD/CAM Milling for custom made Orthotics |

| Function | For Custom Made Orthotic |

IDEASTEP provides a variety of EVA materials, which can be customized for production in terms of color, density, hardness, shape, etc.

Description

multi-layer Laminated Eva Closed Cell Foam Board product picture:

multi-layer Laminated Eva Closed Cell Foam Board Applications:

Stories with Customers

A customer who was approached by Alibaba International sent us a product video during the process of coordinating with our sales team. Our technician thought that the product was very simple and there were no production issues, so we quoted him $5.50. The customer did not negotiate and quickly closed the deal. The customer ordered 5 insoles to test the samples. When the customer received the samples, they were very dissatisfied with the samples and picked out many problems, And compared the products they purchased in the United States, put forward many opinions.

We need high-precision machines to meet customer requirements after evaluation, and the cost will be high. The customer’s target price is over $5.50, which cannot be achieved based on existing conditions. Company personnel want to give up the customer.

At this moment, I remembered the company’s mission, to ensure the happiness of customers. What is customer happiness? How do we make our customers happy? Isn’t it about meeting the value needs of these customers? Helping customers reduce costs? Having the power of mission has changed my way of thinking. Requesting the R&D team to tackle this tough issue, the team later made countless samples and came up with many methods. However, the production process and cost still couldn’t meet the customer’s requirements, and some technicians wanted to give up, At this point, I encourage everyone to say, “If there were no high-precision machines, we wouldn’t be able to make this order. Without equipment, we could still make it. We believe that everyone can do it: when it doesn’t work, it’s the beginning of work! As long as we have a strong desire, we can definitely succeed.” Finally, the big team started to move again, half believing and half believing. After two months of countless designs, samples, and improvements in design, structure, and process, the technical team worked on them; After doing everything possible, a miracle really happened. Without adding more equipment, the team developed a product with high customer requirements at a price half that of their peers. The customer later took a short video to show our team their gratitude for the successful development of the product, and the customer’s face was filled with a happy smile. We have enabled our customers to purchase high-quality and affordable products through this product innovation, allowing them to feel tangible benefits and achieving true happiness for them. Each member of the R&D team also has a strong sense of achievement towards the success of project development. In the current market environment, product innovation is the key to our sustainable development. However, success lies not only in product innovation, but also in how to enhance customer happiness through product innovation, help customer products achieve maximum sales, create lasting competitive advantages for customer products, and ultimately help customers become a high-yield enterprise.

Multi-layer Laminated EVA Closed Cell Foam Board Insoles: Their Unique Characteristics

Multi-layer laminated EVA closed cell foam board insoles offer a range of unique characteristics that make them stand out in the footwear industry. These insoles, made from multiple layers of EVA foam bonded together, provide exceptional comfort, support, and durability.

First and foremost, these insoles excel in comfort. The closed-cell structure of the EVA foam ensures that the material is both lightweight and highly cushioned. This cushioning effect is further enhanced by the multi-layer design, which allows for better shock absorption and impact resistance. As a result, the wearer experiences reduced stress on their feet, ankles, and legs, leading to increased comfort during extended periods of wear.

In terms of support, the laminated EVA foam board insoles are contoured to match the natural curves of the foot. This contouring, combined with the firmness of the closed-cell foam, provides targeted support to specific areas of the foot. This support helps to distribute weight evenly, preventing pain and discomfort associated with prolonged standing or walking.

Durability is another key characteristic of these insoles. The multi-layer laminated construction ensures that the insoles are resistant to compression set and retain their shape and cushioning properties over time. This means that the wearer can enjoy the comfort and support of the insoles for the lifespan of their shoes.