Embracing sustainable practices in EVA block production is crucial for reducing environmental impact and meeting the growing demand for eco-friendly solutions. This article explores various strategies and technologies that B2B enterprises can adopt to enhance the sustainability of their EVA block production processes.

Introduction to Sustainable EVA Block Production

Ethylene Vinyl Acetate (EVA) blocks are widely used in numerous industries for their lightweight and versatile properties. However, the production of EVA blocks often involves significant environmental impacts, such as high energy consumption and waste generation. Adopting sustainable practices is essential for minimizing these impacts and aligning with global sustainability goals. This article discusses eco-friendly solutions and best practices for B2B enterprises in the EVA block production sector.

Key Areas of Focus for Sustainability

To achieve sustainability in EVA block production, enterprises should focus on several key areas:

1. Raw Material Sourcing

The sustainability of EVA block production starts with the sourcing of raw materials. Companies can enhance their environmental performance by:

- Using Recycled Materials: Incorporating recycled EVA and other sustainable materials reduces the need for virgin resources and lowers the carbon footprint.

- Choosing Eco-Friendly Suppliers: Partnering with suppliers who adhere to environmental standards and practices ensures a more sustainable supply chain.

- Implementing Green Chemistry: Utilizing green chemistry principles in the formulation of EVA materials minimizes the use of harmful chemicals and reduces environmental impact.

2. Energy Efficiency

Reducing energy consumption in the production process is another crucial aspect of sustainability. Strategies to improve energy efficiency include:

- Upgrading Equipment: Investing in energy-efficient machinery and technologies can significantly reduce energy use and operational costs.

- Implementing Energy Management Systems: Adopting energy management systems helps monitor and optimize energy consumption throughout the production process.

- Utilizing Renewable Energy: Switching to renewable energy sources, such as solar or wind power, can further decrease the environmental impact of production activities.

3. Waste Management

Effective waste management is essential for reducing the environmental footprint of EVA block production. Companies can adopt the following practices:

- Recycling and Reusing Scrap Material: Implementing systems to recycle and reuse scrap EVA material reduces waste and conserves resources.

- Reducing Production Waste: Optimizing production processes to minimize waste generation and improve yield can lead to more sustainable operations.

- Proper Disposal of Hazardous Waste: Ensuring that hazardous waste is disposed of in an environmentally responsible manner is crucial for preventing contamination.

4. Product Design and Innovation

Designing products with sustainability in mind can significantly impact the overall environmental footprint. Considerations for sustainable product design include:

- Designing for Longevity: Creating durable and long-lasting EVA products reduces the need for frequent replacements and minimizes waste.

- Reducing Material Usage: Using innovative design techniques to reduce the amount of material needed can lower resource consumption and waste.

- Exploring Biodegradable Alternatives: Researching and developing biodegradable EVA materials can offer more sustainable solutions for product disposal.

Case Studies in Sustainable EVA Block Production

Several companies have successfully implemented sustainable practices in EVA block production. Here are a few notable examples:

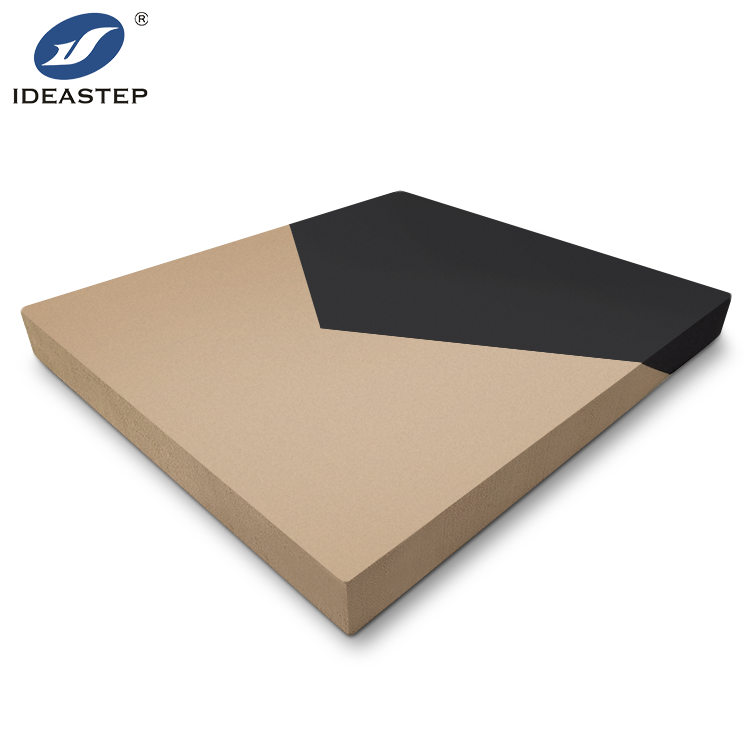

1. Ideastep’s Recycled EVA Blocks

Ideastep has pioneered the use of recycled EVA materials in their block production. By incorporating post-consumer recycled EVA into their products, Ideastep reduces reliance on virgin resources and decreases environmental impact.

2. Energy-Efficient Production Facilities

Several manufacturers have invested in energy-efficient machinery and renewable energy sources to reduce their production facilities’ carbon footprint. These investments not only lower energy consumption but also lead to cost savings over time.

3. Waste Reduction Initiatives

Companies have implemented waste reduction initiatives, such as advanced recycling programs and process optimization, to minimize waste and improve resource efficiency. These initiatives have resulted in significant reductions in production waste and better environmental performance.

Benefits of Sustainable Practices

Adopting sustainable practices in EVA block production offers numerous benefits:

1. Environmental Impact Reduction

By implementing eco-friendly solutions, companies can significantly reduce their environmental footprint, contributing to global sustainability efforts and mitigating the effects of climate change.

2. Cost Savings

Energy-efficient technologies and waste reduction practices can lead to substantial cost savings by lowering energy bills and reducing material waste.

3. Enhanced Brand Reputation

Companies that prioritize sustainability are often viewed more favorably by customers and stakeholders. This can lead to improved brand reputation, increased customer loyalty, and a competitive advantage in the marketplace.

Conclusion

Sustainable practices in EVA block production are essential for reducing environmental impact and meeting the increasing demand for eco-friendly solutions. By focusing on raw material sourcing, energy efficiency, waste management, and innovative product design, B2B enterprises can enhance their sustainability efforts and contribute to a greener future. Embracing these practices not only benefits the environment but also offers economic advantages and strengthens brand reputation.

FAQ

1. What are the benefits of using recycled EVA materials?

Using recycled EVA materials reduces the need for virgin resources, lowers carbon emissions, and helps manage waste more effectively, contributing to a more sustainable production process.

2. How can companies improve energy efficiency in EVA block production?

Companies can improve energy efficiency by upgrading to energy-efficient machinery, implementing energy management systems, and utilizing renewable energy sources.

3. What are some innovative approaches to sustainable product design?

Innovative approaches include designing for longevity, reducing material usage, and exploring biodegradable alternatives to enhance sustainability and minimize environmental impact.