Advanced EVA customization has really revolutionized the way products are being made for specific needs, especially in those areas that require great precision, durability, and flexibility. My desire to have an advanced EVA customization came about when there was a need for a product that was heavily used but at the same time gave enhanced performance. Through this experience, I came to realize various benefits accruing from it, which met and even surpassed my expectations. The paper shall discuss these benefits, give insight into the customization process, and useful tips that one may want to consider in advanced EVA customization.

I. Understanding Advanced EVA Customization

What is Advanced EVA Customization?

Advanced EVA customization deals with a process of tailoring EVA materials to meet particular specifications accurately. The process is important in several industries that rely on standard EVA materials, which are insufficient for production, sports equipment, and even footwear.

Why I Chose Advanced EVA Customization

There was a specific reason why I chose advanced EVA customization. I needed something that could handle more extreme usage and could still perform well. The standard options for EVA that were provided did not have the precision or be strong enough, so I looked for customized options.

II. Advantages of Advanced EVA Customization

Above all, advanced EVA customization enhances performance through precision

Among the most fundamental advantages I received was the performance of the product. The personalization allowed for an exact fit and modifications that standard EVA material is not capable of. In a high-impact application, for example, customized EVA provided better shock absorption and durability.

Design Flexibility

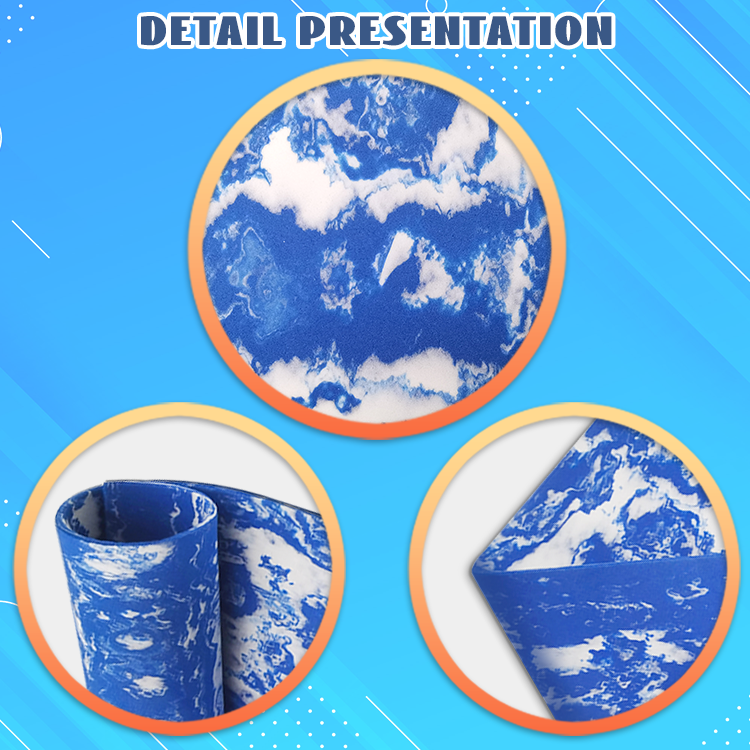

With advanced EVA customization, great design flexibility was achieved that allowed the material to be tailor-made to specification. It was quite helpful for developing a product that should meet functional requirements but also possess aesthetic appeal of a superior nature.

Long-Lasting

Durability is one of the very important factors when it comes to the use of materials for industrial purposes. Advanced customization with EVA significantly improved product longevity. The customized material could resist wear and tear far more than off-the-shelf replacements, hence resulting in a longer life, which in turn reduces maintenance costs.

III. Surpassing Challenges by Advanced EVA Customization

Initial Hurdles

Of course, it wasn’t a smooth sail from the very beginning. Initial customization was rather complex, with careful consideration needed in various factors, including material composition and processing techniques. This was overcome through iteration and testing in collaboration with experts.

Lessons Learnt

Through this experience, I learned the importance of patience and paying attention to detail in the process. Advanced EVA customization is not an out-of-the-box solution, but a project-specific approach that has to be carefully tailored if the best results are ever to be achieved.

IV. Personal Experience with Advanced EVA Customization

Product Evolution

The product was significantly dissimilar between the prototype and the final customized model. Performance and durability were the most astounding aspects; much better when compared to the standard EVA.

Satisfaction of Final Result

Looking back, I am particularly satisfied with the result. The EVA customization was up-to-date, achieving the purpose for which I intended to achieve, besides a few accessories of aesthetic beauty in the product and of course cost effectiveness in the long run.

V. Frequently Asked Questions

1. How does advanced EVA customization enhance the performance of any product?

Advanced EVA customization makes possible the perfect pre-definition of material properties according to an application, therefore guaranteeing enhanced performance such as better shock absorption, durability, and flexibility.

2. What should be considered when embarking on advanced EVA customization?

It is very important to understand the specific needs of the application in question, selection of appropriate material properties is required, and working with expert manufacturers is critical for the best outcome.

3. Are there any disadvantages of advanced EVA customization?

Yes, the major one is that it may cost more up front and take longer to develop than regular EVA products. These are generally offset by the benefits over the long term, however.

4. How does advanced EVA customization compare to the cost of standard EVA?

Advanced EVA customization may cost more but pays for itself by being more durable and performing better with less maintenance or a longer product life.

5. What kind of industries benefits most from advanced EVA customizations?

Manufacturers of sports equipment, cars, and footwear benefit the most from advanced EVA customization, due to needs that involve very specific material properties, along with toughness.

If you are interested in EVA , you can continue to visit this page (https://www.eva-block.com/product/) and tell us your needs.