EVA sheets are quickly becoming part and parcel of modern production. The sheets have become core in improving the efficiency of manufacturing due to their flexibility, strength, and resilience to shock. In this paper, the description of how the EVA sheets enhance different manufacturing operations in a bid to save money and improve the quality of a product. The definitions include:

1. EVA Sheets

What Are EVA Sheets?

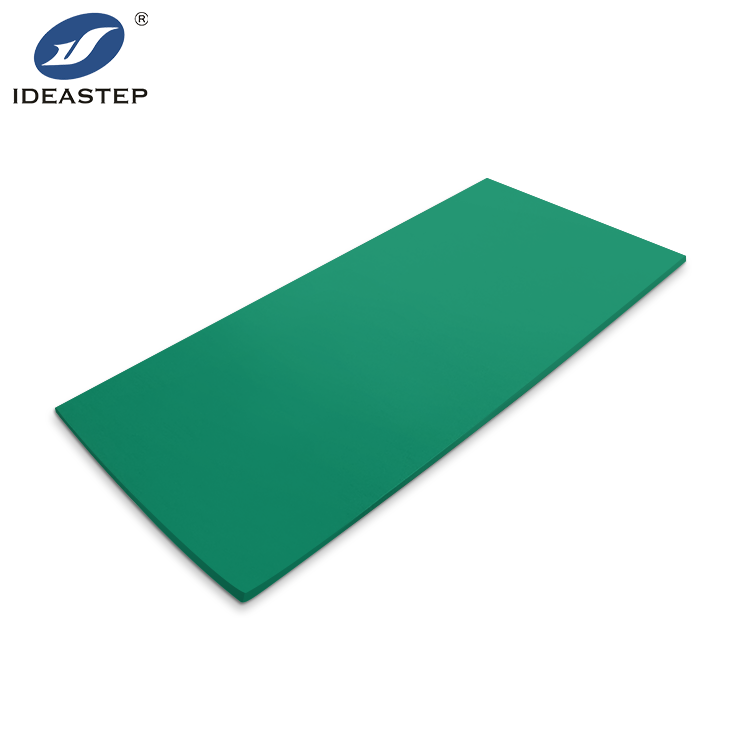

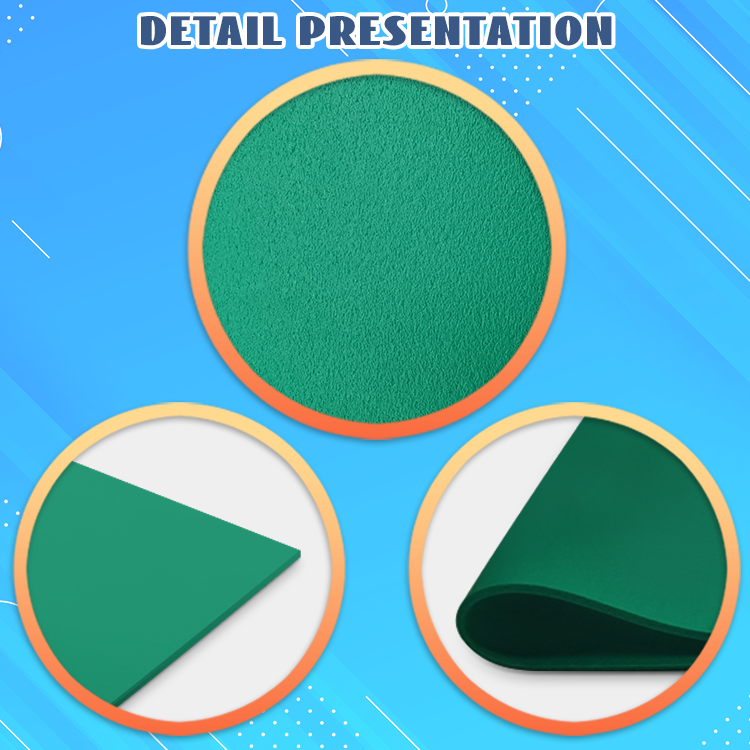

EVA sheets have an ethylene and vinyl acetate composition, which gives a very elastic and shockproof quality while being tough. They have an added advantage with respect to stress, other than being lightweight. EVA sheets, therefore, become very important in a number of different applications in relation to manufacturing, right from automotive to packaging.

Types of EVA Sheets

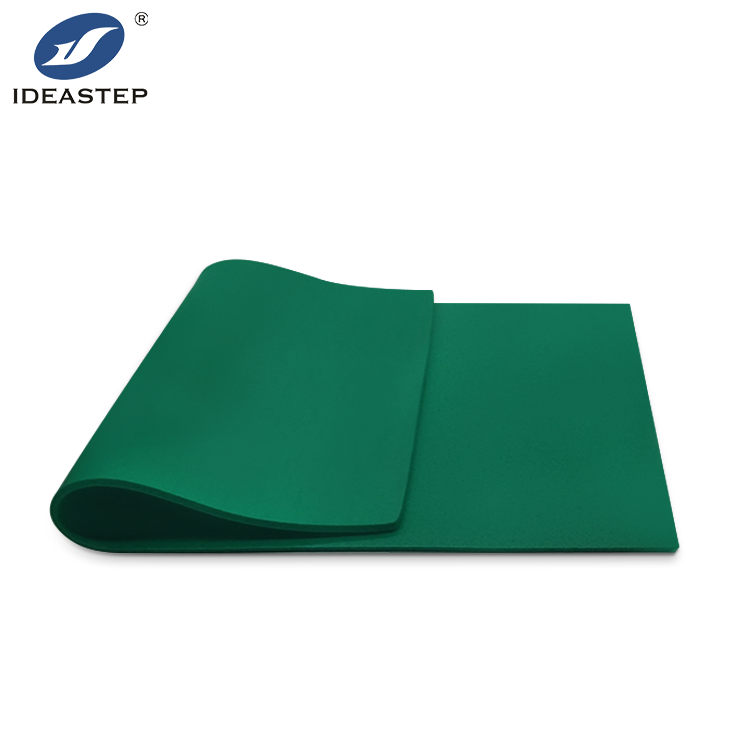

EVA sheets are manufactured in varied grades and thicknesses according to applications. For example, high-density EVA sheets are firmer and more supportive than the low ones that are more flexible. Selection of the right kind is attributed to the purpose of manufacturing and end use of the product.

2. Bettering Manufacturing Processes through EVA Sheets

Better Quality Product

EVA sheets provide a better quality of products by ensuring that they are shock-absorbent and durable, which therefore reduces issues of wear and tear in products and elongates their life and continued performances.

Reduces Production Costs

Using EVA sheets in production can help to achieve cost savings. They are relatively durable, thus requiring a reduced number of replacements and repairs that would otherwise increase expenditures on materials and labor. Besides, EVA sheets very often cost cheaper compared to alternative materials with similar properties.

Rationalizing Production

EVA sheets simplify the manufacturing process in many ways. For example, the easy bending and cutting allow special applications to be done without complicated machinery or extra steps, the time for production will be shortened, and higher efficiency will be achieved.

3. Case Studies and Industry Examples

Automotive Industry

EVA sheets are integrated into the automobile industry for noise control and insulation. They help to reduce vibrations and therefore increase the general comfort in the vehicle. The use and integration of EVA sheets in such vehicles allow it to be possible to give a superior driving experience and meet higher standards of noise control.

Footwear Industry

EVA sheets are thus widely used in the footwear industry because of their features in comfort and performance. These are used in insoles and midsoles to offer cushioning and support features that bring out the desired comfort by the individual while at the same time tending towards reduction of fatigue on the feet.

Packaging Industry

The dampening capabilities of EVA sheets perfectly assure your products by protecting their brow, which minimizes damage and returns.

4. The Advantages of Using EVA Sheets

Versatility and Customization

EVA sheets can be customized in various methods to meet several manufacturing needs. The main properties of EVA are easy molding to any intended form and size, making it an efficient material in automotive components and consumer products industries.

Sustainability

EVA sheets have a series of environmental attributes, with benefits for being recyclable, reduced environmental impact compared to other materials, and supporting manufacturers’ capabilities to become sustainable using the EVA sheets.

Performance Benefits

High wear resistance of the EVA sheets allows for a long-lasting performance. Their gas-cushioning properties make them a higher performance product in the long run since on top of it, the benefits apply in many different industries, making it a very useful material.

5. Challenges and Considerations

Material Limitations

As described, although EVA sheets have many advantages, they do also have some limitations. For example, they may not be used for extremely high-temperature applications. It is very important for a designing engineer to know these limitations when selecting EVA as a material for specific needs.

Cost Considerations

The factors that can then justify the price of EVA sheets were the grade, thickness, or supplier. This makes the reason for manufacturers doing cost–benefit analysis—to weigh cost against cost savings and performance advantage—important.

Conclusion

EVA Sheets carry an exceptionally important role in the improvement of manufacturing efficiency by enhancing product quality, reducing costs, and improving the manufacturing process itself. When producers are aware of both the positive and negative attributes associated with EVA sheets, then they can pursue overall success in operations by making informed decisions.

Frequently Asked Questions

What are EVA sheets and what are they used for in manufacturing?

EVA stands for ethylene-vinyl acetate. EVA sheets are flexible, highly durable sheets with shock-absorbing properties, ideal for numerous manufacturing functions.

How do EVA sheets help reduce manufacturing costs?

It costs less if it needs to be replaced less frequently and has a good chance of costing less than most other similar materials.

Can EVA sheets be manufactured to meet custom manufacturing requirements?

Yes, EVA sheets can be made to suit relatively specific manufacturing requirements in terms of grade, thickness, and shape.

What are the eco-friendly characteristics of using EVA sheets?

EVA sheets are highly recyclable, with much less ecological damage when compared with some other materials, therefore providing an ecological solution for many manufacturers.