Introduction

Choosing suitable EVA blocks for industrial purposes is not an easy task, especially when the main issue is durability. Therefore, this tutorial will easily enable you to choose the most durable EVA blocks which best suit your needs. By understanding some of the important factors that involve material composition, density, and temperature tolerance, one is easily able to conduct an impeccable operation with outstanding efficiency.

EVA Blocks for Industrial Purposes

What is an EVA Block, and why is it utilized in the industry?

EVA blocks are manufactured from Ethylene Vinyl Acetate and find their applications in industries because of their flexibility, light weight, and resilience. These blocks are used for a number of purposes, like cushioning, insulation, and absorption of shock, which makes this material a perfect choice to be used in industries.

Importance of Durability in EVA Blocks for Industrial Purposes

However, in an industrial setting, EVA blocks can be put under extreme conditions: high temperature, extreme friction force, and tension among others. A choice based on the durability of EVA blocks will go a long way in ensuring efficiency and safety for a long period. Durability means that EVA blocks are resistant to wear and tear, hence suitable for applications with strong tension or friction.

Factors to Consider When Selecting Durable EVA Blocks

Material Composition: Ensuring Quality in EVA Blocks

Most of the quality about EVA blocks is determined by the material composition. Good-quality EVA blocks are those made from quality materials that give durability. While buying, check blocks that have a consistent composition and less filler.

Density and Hardness: The Factors Showing the Durability of the EVA Block

The two critical factors that will define how durable EVA blocks are, include density and hardness. Higher density and appropriate hardness ensure that the blocks can withstand heavy loads and will not deform over time, thus finding their application in industry.

Temperature Resistance: Selection of EVA Blocks for Extreme Conditions

Therefore, in industries that are subjected to temperature changes, the selection of EVA blocks should be done in a manner that at extreme temperatures, the blocks do not lose their structural integrity. Temperature-resistant EVA blocks withstand damage and uphold the performance in the most adverse conditions.

Compression and Shock Absorption: Two Most Important Features of Industrial EVA Blocks

With that in mind, the resistance to compression by such sudden impacts, among other violent effects, will be highly necessary for industrial applications. Long-lasting EVA blocks should absorb such shocks, elastically deform, and return to their original shape, continuing protection and performance.

Comparing Different Products of EVA Blocks

How to Compare EVA Blocks in the Market for Durability

During the comparison between EVA blocks, some of the key things to pay attention to include material quality, density, and temperature resistance. This will be achieved by reading the product specification and customer review about different EVA blocks in the market.

Best Brands of EVA Blocks Based on Durability

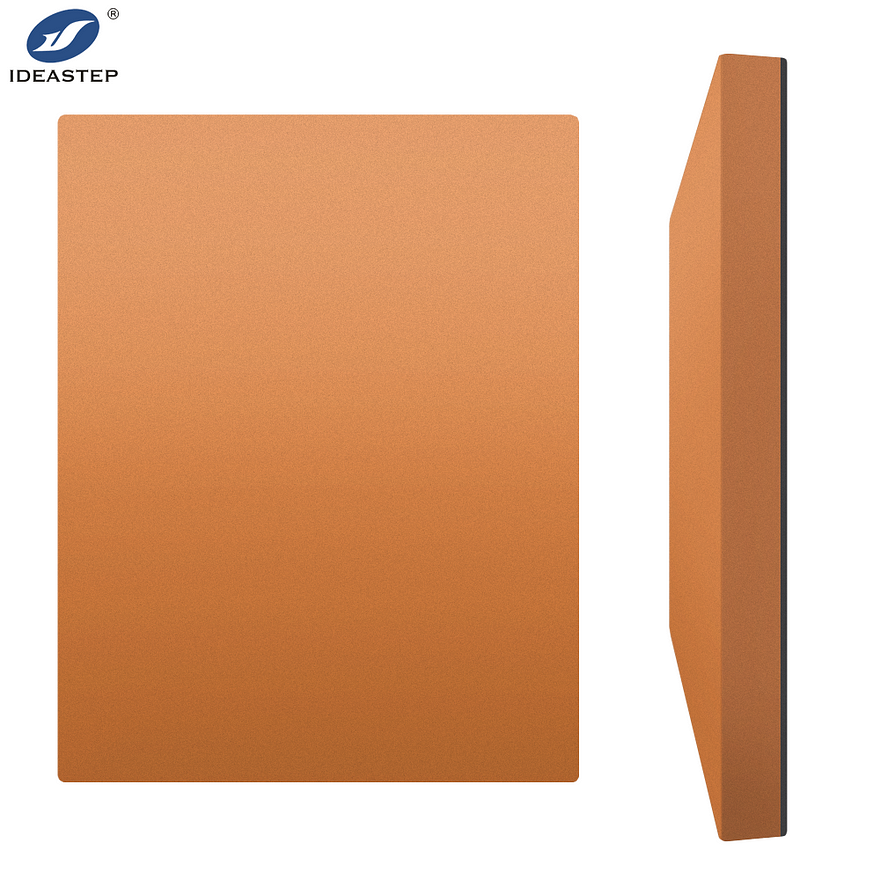

Some of the brands known to manufacture good quality and durable EVA blocks include Ideastep. Buying from reputable brands ensures that you get a product that is up to industrial standards and will serve longer.

Personal Experience

As a customer who has used Ideastep EVA blocks, I can confidently guarantee that they are tough for industrial purposes. The blocks did a great job in shock absorption and never lost their shape, even with heavy loads. I highly recommend them to anyone looking for durable EVA blocks in an industrial setting.

Frequently Asked Questions (FAQs)

1. What are the most effective EVA blocks on the market suitable for heavy-duty industrial applications?

The best EVA blocks for heavy-duty industrial use would be those rated high in terms of density and with very good compression resistance. Blocks by well-established brands, such as Ideastep, have been designed especially for heavy-duty applications and will be able to keep pace with performance even after a long period of stress.

2. How will I know that the EVA blocks I am purchasing are durable?

Durability in EVA blocks can be ascertained by examining product specifications for density, hardness, and temperature resistance. Other than reading customer reviews, selecting blocks from well-known manufacturers should include durability in using EVA blocks.

3. Are EVA blocks resistant to extreme temperatures?

Yes, some EVA blocks can bear very high temperatures. During purchase, you must make a request for high-temperature-resistant blocks, which would be apt for applications where the temperature variations are high.

4. What should be the ideal thickness of an EVA block used in industry?

The thickness of EVA blocks for industrial use depends on the purpose of application. Generally speaking, thicker blocks, which are around 20mm to 50mm, have more shock absorbance and compression resistance. These are quite suitable for heavy-duty use in an industrial context.

5. Are there any specific brands that offer more durable EVA blocks?

Brands like Ideastep have a reputation for providing durable EVA blocks that are engineered for industrial use. Acquiring blocks from such a reputable brand ensures high quality and durability for better value for money in your investment.

If you are interested in EVA blocks , you can continue to visit this page (https://www.eva-block.com/product/) and tell us your needs.