User feedback on the ease of handling and installation of 50mm thick EVA foam sheets provides valuable insights into their practical application. This article investigates the experiences of clients who have worked with these foam sheets, highlighting key factors that impact their convenience and effectiveness.

Introduction to 50mm Thick EVA Foam Sheets

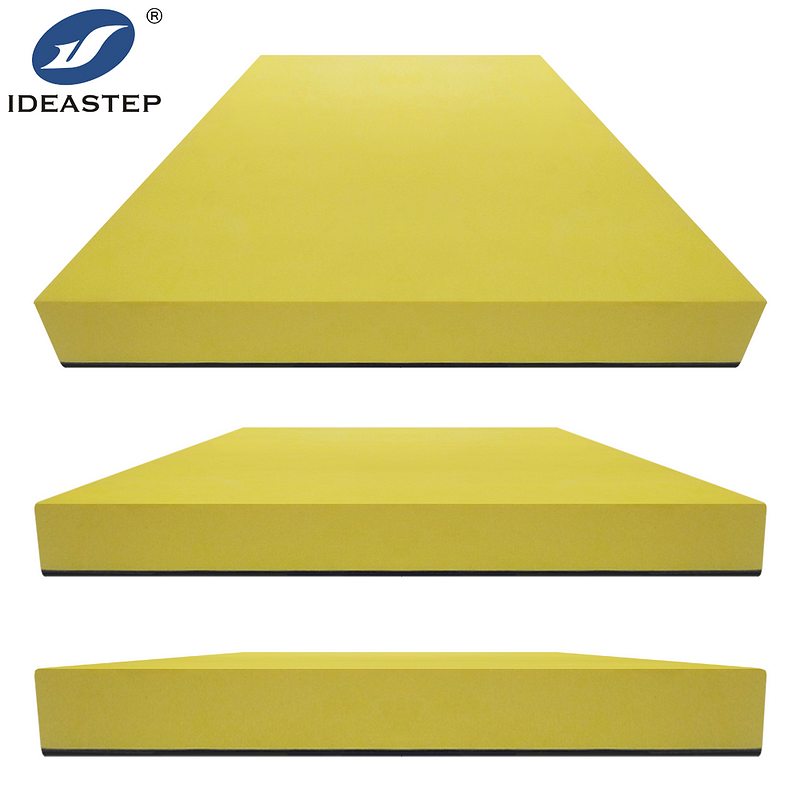

Ethylene-vinyl acetate (EVA) foam is well-known for its adaptability and durability, making it a popular option for a variety of applications, including cushioning and flooring. Among the various thicknesses available, 50mm thick EVA foam sheets are notable for their significant cushioning and insulation properties. Understanding user feedback on these sheets can provide essential information for both suppliers and buyers, helping to enhance product usability and performance.

Ease of Installation

The ease of installation is one of the primary concerns when using 50mm thick EVA foam sheets. Feedback from users frequently centers around several key aspects:

- Cutting and Shaping: Many users find that 50mm thick EVA foam sheets are relatively easy to cut and shape using standard tools such as utility knives or hot wire cutters. This flexibility allows for various projects to be tailored to specific needs.

- Adhesion: Adhesion to surfaces is generally straightforward, with users reporting that the foam adheres well when using recommended adhesive products. Ensuring surfaces are clean and dry before application can enhance adhesion.

- Handling: The foam’s lightweight nature, despite its thickness, makes handling and positioning manageable. Users have noted that the foam can be easily moved and adjusted during installation, reducing the overall effort required.

Handling and Maintenance

Handling and maintenance are critical factors in determining the long-term usability of EVA foam sheets. User feedback highlights several important considerations:

- Durability: Users consistently report that 50mm thick EVA foam sheets offer excellent durability and resilience even under heavy use. The foam’s longevity is attributed to its ability to return to its original shape after compression.

- Cleaning: Cleaning EVA foam sheets is relatively simple. Most users recommend using mild soap and water to remove dirt and debris, avoiding harsh chemicals that could damage the foam.

- Storage: Proper storage is essential to maintain the foam’s quality. Users suggest storing the sheets in a cool, dry place away from direct sunlight to prevent degradation over time.

Applications and Versatility

50mm thick EVA foam sheets are valued for their versatility in various applications. Based on user feedback, these foam sheets are used in several ways:

- Flooring: Many users utilize these foam sheets for flooring solutions, appreciating their cushioning effect and shock absorption capabilities, making them ideal for gyms, play areas, and industrial settings.

- Packaging: The foam’s shock-absorbing properties are beneficial for packaging delicate items. Users highlight its effectiveness in protecting goods during transportation.

- Cushioning and Insulation: EVA foam sheets are commonly used for cushioning and thermal insulation. Users find them effective in reducing noise and providing thermal protection in various environments.

Common Challenges and Solutions

While 50mm thick EVA foam sheets offer numerous benefits, users also encounter some challenges. Feedback often includes common issues and practical solutions:

- Edge Fraying: Some users experience fraying at the edges when cutting the foam. To minimize this, it is recommended to use sharp, clean cutting tools and to seal the edges with a light application of adhesive or edge tape.

- Odor: New EVA foam sheets may emit a slight odor. Users can reduce this by allowing the foam to air out in a well-ventilated area before installation.

- Thickness Variability: Occasionally, users report slight thickness variations in different sheets. Choosing a reputable supplier and conducting a quality check upon delivery can help address this issue.

Conclusion

User feedback on 50mm thick EVA foam sheets highlights their ease of handling, installation, and versatility in applications. Despite some minor challenges, the overall consensus emphasizes the foam’s effectiveness and user-friendly nature. By considering user experiences and addressing common issues, suppliers and buyers of EVA foam products can enhance their utility and customer satisfaction.

FAQ

What advantages do 50mm-thick EVA foam sheets offer?

The advantages include being simple to cut and shape, adhering well, being lightweight, being durable, being easy to maintain, and being versatile for flooring, packaging, and insulation applications.

How do I properly handle and store EVA foam sheets?

To prevent damage, handle the sheets gently and store them in a cool, dry location away from direct sunlight. Clean them with mild soap and water and avoid using harsh chemicals.

What are common issues with EVA foam sheets and how can they be resolved?

Common issues include edge fraying, odor, and thickness variability. Use sharp tools for cutting, allow the foam to air out to reduce odor, and select a reputable supplier to minimize thickness discrepancies.