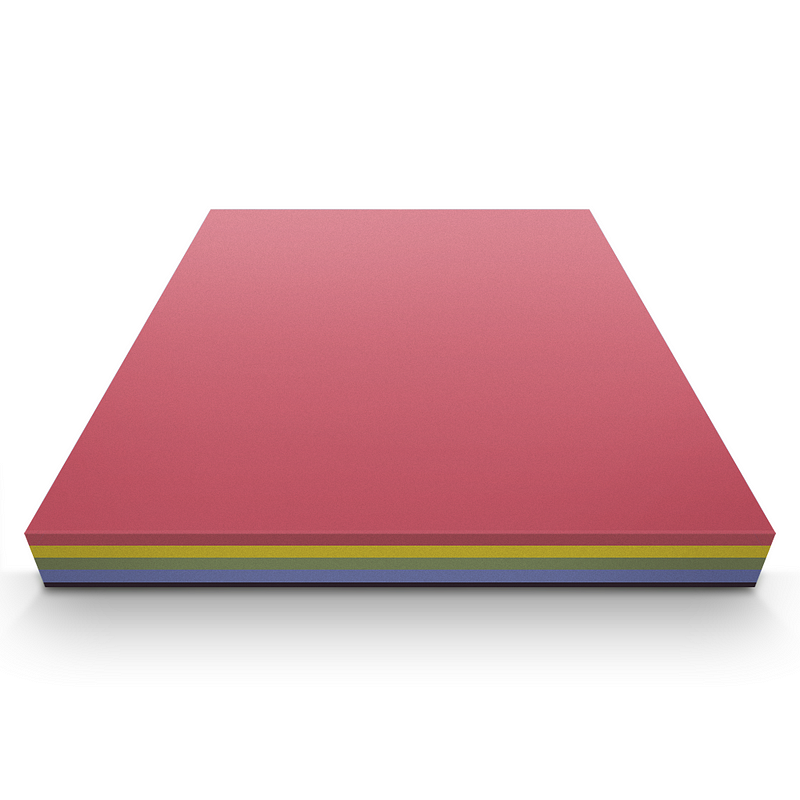

EVA CAD CAM milling blocks offer a range of benefits for custom jewelry designers, including precision, versatility, and cost-effectiveness. These blocks facilitate intricate designs and prototyping, streamlining the design process while enhancing accuracy and efficiency in the creation of custom jewelry pieces.

In the world of custom jewelry design, precision and efficiency are crucial. EVA CAD CAM milling blocks have emerged as a valuable tool for designers seeking to streamline their design process while maintaining high standards of quality. These blocks, made from ethylene-vinyl acetate (EVA), offer numerous advantages in the realm of jewelry design and production. This article explores the key benefits of using EVA CAD CAM milling blocks and how they can enhance the workflow of custom jewelry designers.

1. Enhanced Precision and Detail

One of the most significant advantages of EVA CAD CAM milling blocks is their ability to deliver exceptional precision. The material’s consistent density and stability allow for intricate designs and fine details to be accurately milled. This precision is essential for creating complex jewelry pieces with intricate patterns, engravings, and settings. The high accuracy provided by EVA milling blocks ensures that the final product closely matches the designer’s vision, reducing the need for extensive modifications or reworking.

2. Versatility in Design

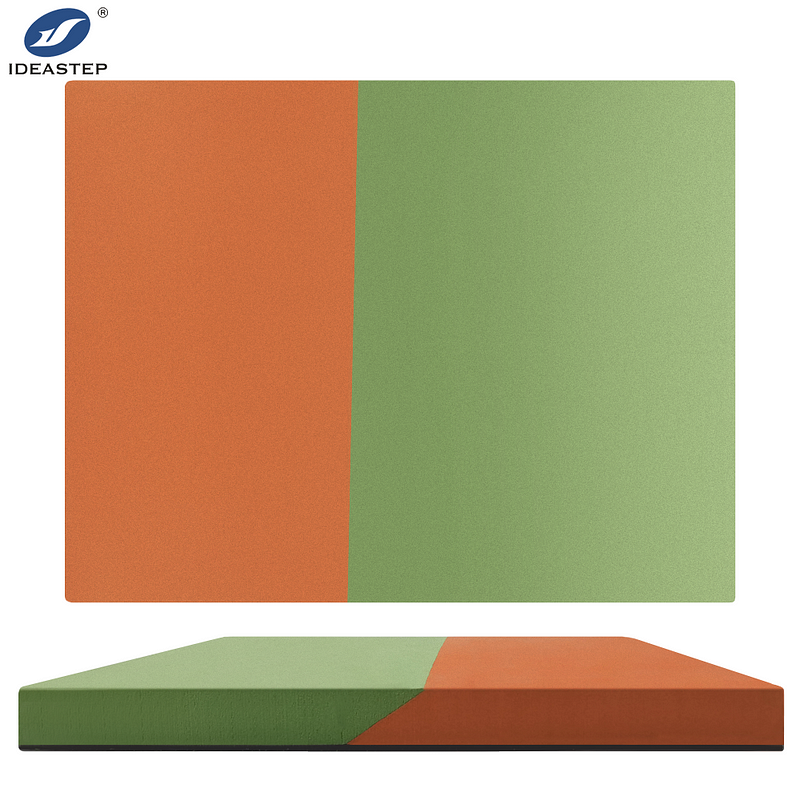

EVA CAD CAM milling blocks offer remarkable versatility, making them suitable for a wide range of jewelry design applications. Whether designing engagement rings, necklaces, earrings, or other custom pieces, EVA blocks can accommodate various design styles and complexities. The material can be easily shaped and adjusted, allowing designers to experiment with different designs and techniques. This flexibility enables designers to bring their creative ideas to life and explore new design possibilities without limitations.

3. Cost-Effectiveness

Cost is always a consideration in jewelry design, and EVA CAD CAM milling blocks provide a cost-effective solution for designers. Compared to traditional wax models or other prototyping materials, EVA blocks are generally more affordable. The lower cost of EVA blocks allows designers to produce multiple prototypes without significant financial investment. This cost efficiency is especially beneficial for designers working on multiple projects or seeking to test various design concepts before final production.

4. Efficient Prototyping Process

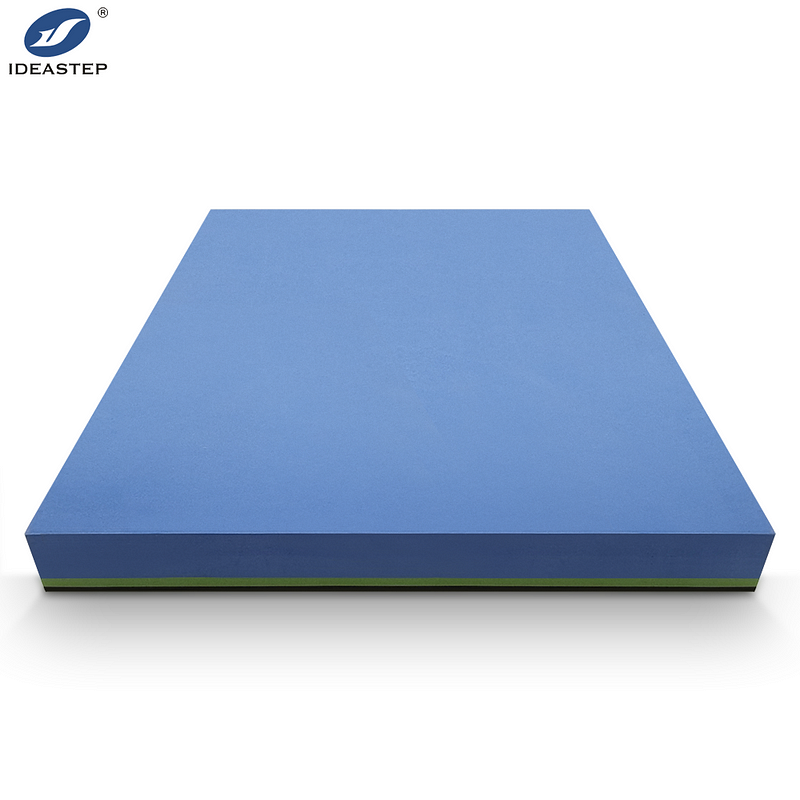

The use of EVA CAD CAM milling blocks significantly streamlines the prototyping process. The blocks can be easily milled using CAD CAM machines, which automate the cutting and shaping process. This automation reduces the time required to produce prototypes and minimizes manual labor. Designers can quickly create accurate models of their designs, making it easier to assess the final appearance and make any necessary adjustments before proceeding to the final production stage.

5. Smooth Surface Finish

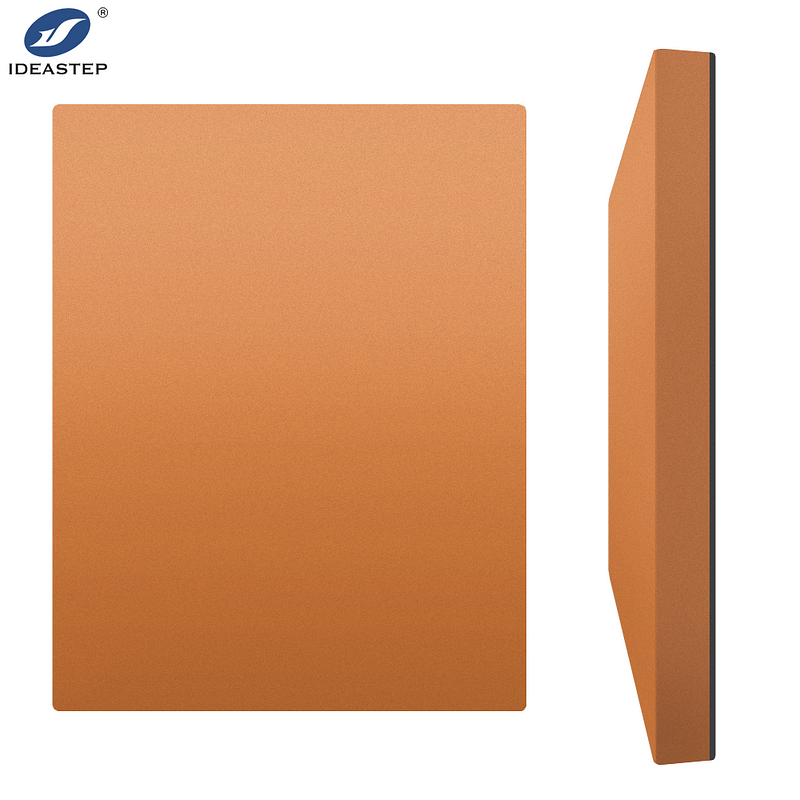

EVA milling blocks are known for their ability to achieve a smooth surface finish. The material’s fine texture and consistency result in prototypes with a polished appearance, closely resembling the final jewelry piece. This smooth finish is essential for evaluating the design’s aesthetics and ensuring that the final product will meet the desired quality standards. Designers can present their prototypes to clients with confidence, knowing that the finished product will reflect the high standards of their work.

6. Reduced Environmental Impact

Environmental considerations are becoming increasingly important in the jewelry industry. EVA CAD CAM milling blocks offer an eco-friendly alternative to traditional prototyping materials. EVA is a recyclable material, and using EVA blocks reduces the environmental impact associated with waste from other materials. By choosing EVA blocks, designers can contribute to more sustainable practices in the jewelry design and manufacturing process.

7. Compatibility with CAD CAM Technology

EVA blocks are specifically designed to work seamlessly with CAD CAM technology. This compatibility ensures that designers can fully leverage the capabilities of modern milling machines and software. The precise and consistent properties of EVA blocks enhance the accuracy of the CAD CAM process, resulting in high-quality prototypes that accurately represent the designer’s vision. This integration of technology and material streamlines the design workflow and improves overall efficiency.

Conclusion

EVA CAD CAM milling blocks provide custom jewelry designers with numerous benefits, including enhanced precision, versatility, cost-effectiveness, and efficient prototyping. The ability to achieve detailed designs, reduce costs, and produce high-quality prototypes makes EVA blocks an invaluable tool in the jewelry design process. By incorporating EVA CAD CAM milling blocks into their workflow, designers can elevate their creative capabilities and streamline their production processes, ultimately delivering exceptional custom jewelry pieces.

FAQ

1. How does EVA compare to other prototyping materials?

EVA is generally more affordable and versatile compared to traditional materials like wax. It also provides a smooth finish and is compatible with CAD CAM technology, making it a popular choice for custom jewelry prototyping.

2. Can EVA CAD CAM milling blocks be used for all types of jewelry designs?

Yes, EVA CAD CAM milling blocks are versatile and can be used for a wide range of jewelry designs, including rings, necklaces, earrings, and more. They accommodate various design complexities and styles.

3. Are EVA blocks environmentally friendly?

EVA is a recyclable material, making it a more eco-friendly option compared to some other prototyping materials. Using EVA blocks helps reduce the environmental impact associated with waste from other materials.