What Are the Key Factors to Consider When Buying EVA Foam?

EVA foams are popular due to their versatility, durability, and comfort. Whether you are buying for sports equipment, flooring, packaging, or any other purpose, selecting the right foam is essential. Here are some key factors to consider when purchasing EVA foams to ensure you make the correct choice for your needs.

1. Density

Of all selected parameters for EVA foam, density stands out as the most crucial. Density determines whether the foam will have strength, cushioning properties, and overall performance. Generally, the higher the density, the more durable the EVA foam will be, making it suitable for applications such as sports equipment and protection gear, where better shock absorption is needed. Conversely, lower densities result in lighter, more flexible foam, ideal for uses like packaging and short-term cushioning. Always match the foam density with the specific requirements of your application.

2. Thickness

The thickness of EVA foam relates to the level of cushion and comfort it can provide. Thicker foams offer more comfort and shock absorption, making them suitable for applications like flooring or mats. However, if the foam needs to fit into tight spaces or serve light packing, a thinner foam might be appropriate. Consider your project’s specific requirements and choose the thickness that balances comfort and usability.

3. Compression Set

Compression set refers to the foam’s ability to return to its original shape after being compressed. A low compression set means that the foam will recover well after pressure, making it suitable for long-term applications where it will frequently experience compression. This property is critical for sports mats, seat cushions, and other items subject to frequent indentation. Ensure that the foam has a good recovery rate to support long-term performance.

4. Temperature Resistance

EVA foams are sensitive to temperature. Some foams can withstand extreme temperatures, while others may become brittle or less flexible under high or low temperatures. Consider the temperature resistance of the foam based on where and how you intend to use it. For outdoor or temperature-varying environments, opt for foams with high thermal stability.

5. UV Resistance

UV resistance is crucial for EVA foam exposed to sunlight or other sources of UV radiation. UV exposure can degrade the foam, making it brittle or discolored over time. For products used outdoors or in bright environments, choose EVA foam with UV stabilizers or additives to enhance longevity and maintain aesthetic value.

6. Water Resistance

Water resistance should be considered if the foam will be exposed to moisture or high humidity. While EVA foam is generally water-resistant, the degree of resistance can vary. For items used in wet conditions or where moisture may be present, select foam with high water resistance to prevent issues like swelling or degradation.

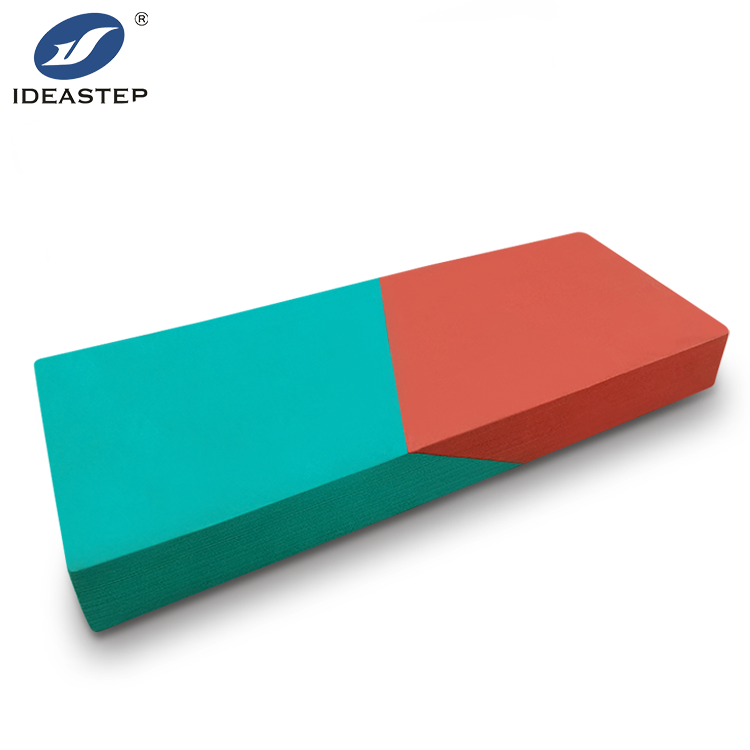

7. Color and Aesthetic

While functionality is paramount, aesthetics can be important for consumer-facing products. EVA foam can be colored or printed to meet specific design requirements. When purchasing, consider whether the foam needs to match a color scheme or branding and check if the supplier offers customization options.

8. Environmental Impact

With increasing environmental awareness, choosing eco-friendly EVA foam is important. Some manufacturers offer foam made from recycled materials or with reduced environmental impact. If sustainability is a priority, look for options that align with green practices or certifications.

9. Cost

Cost is a significant factor in any purchasing decision. While balancing quality and performance, it’s crucial to stay within budget. Compare prices from different suppliers and consider factors such as foam density, thickness, and additional features. Sometimes investing a little more initially can lead to better performance and longevity, ultimately saving money in the long run.

FAQ

Q: How do I determine the right density for my EVA foam application?

A: The correct density depends on the application. Higher density foams provide better durability and impact resistance, while lower density foams are more lightweight or flexible. Assess your specific needs to select the appropriate density.

Q: What is the right thickness for EVA foam flooring?

A: A thicker foam provides more comfort and shock absorption on floors. Common thicknesses for flooring applications range from 10 mm to 20 mm, but the exact thickness will depend on individual comfort preferences and the level of cushioning required.

Q: Why is UV resistance important for EVA foams?

A: UV resistance is important when EVA foam is exposed to sunlight or bright environments. UV rays can degrade the foam over time, causing brittleness or discoloration. UV-resistant foam ensures longer-lasting performance and appearance.