What Factors Influence the Performance of EVA Blocks?

From sports to construction, EVA blocks find a place in several diversified industries due to the versatility and performance characteristics they offer. But what factors really affect the performance of these blocks? Let’s delve into the key factors playing a crucial role.

1. EVA Block Composition

The chemical composition of the EVA blocks is an important factor controlling the ultimate performance delivered by them. EVA stands for ethylene vinyl acetate copolymer. The relative ratio of these two ingredients can significantly change the block’s characteristics in many aspects, including flexibility, durability, and density. For example, if vinyl acetate is added in a greater proportion in the material, then it will relatively be softer and more flexible; otherwise, it may be more rigid and tough with a lesser proportion. Different manufacturers, such as Ideastep, change the composition to cater to this type of requirement.

2. Manufacturing Process

Even the method of processing EVA blocks may affect their performance. The two typical technologies to do this are extrusion and molding, both with benefits associated with the process. Extrusion involves the forcing of EVA material through a die to produce blocks of uniform shape and size. In molding, more complex designs and structures can be implemented. Further, the temperature and pressure conditions finally affect the properties in the blocks, relating to density and resilience.

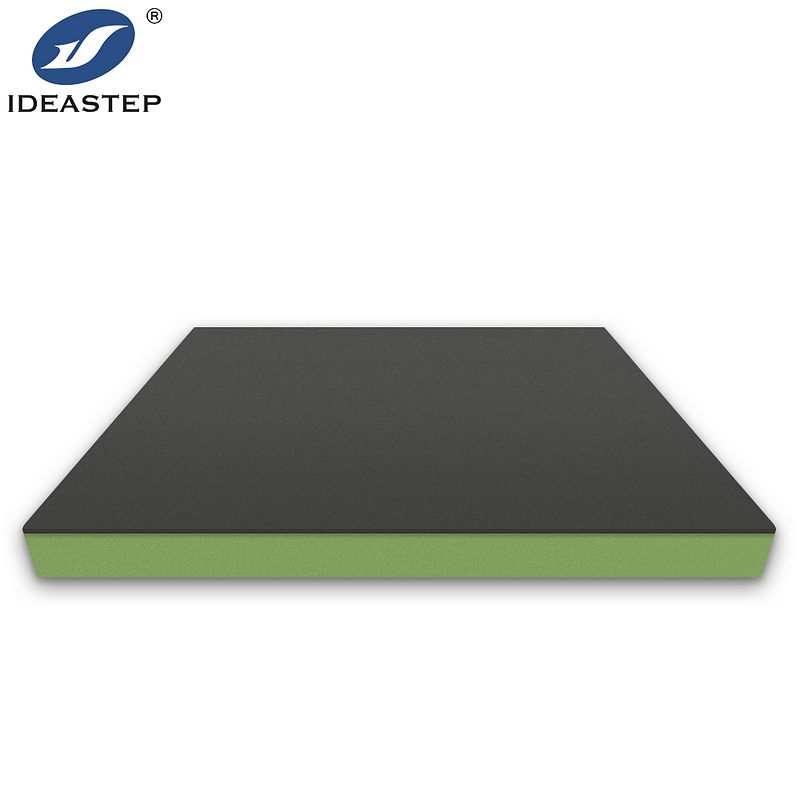

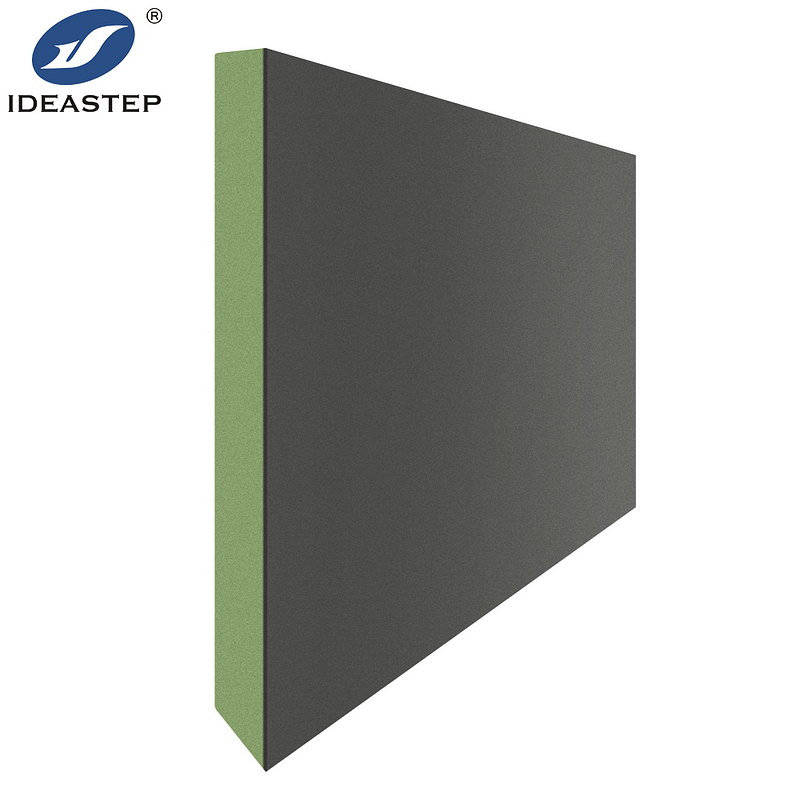

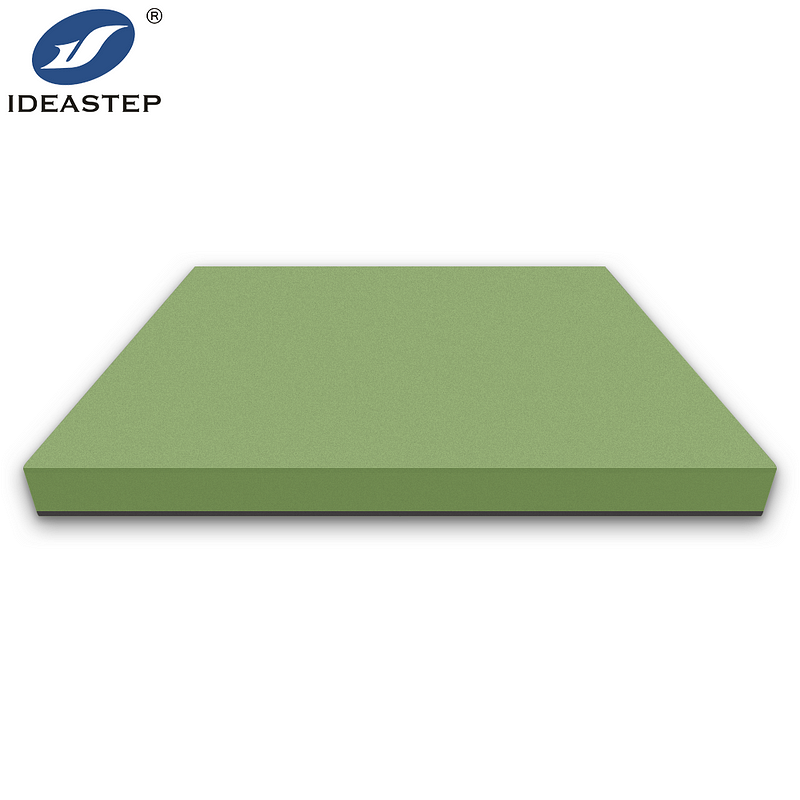

3. Density and Thickness

Performance essentially depends on the density and thickness of EVA blocks. Generally, blocks with higher density will have more excellent shock absorption and thus better durability, making them appropriate for applications such as sports flooring or padding. In contrast to low-density blocks, which are very light and easily compressible, they find favor in a wide array of applications, from sports shoes to packaged products. Changing the block thickness will also impact how these blocks service their applications effectively.

4. Environmental Conditions

EVA blocks are subjected to various environmental conditions, such as temperature changes, relative humidity, and exposure to UV. This may alter the durability and performance of the same. For example, if an EVA material is exposed to UV for a long duration, it undergoes degradation with an increase in brittleness, hence reduced performance. To this effect, most manufacturers include some additives that enhance UV resistance and, therefore, durability of the block under such challenging conditions.

5. Additives and Modifiers

Additives and modifiers can be added to the blocks to enhance the properties of the block, such as plasticizers for improved flexibility, fillers for adjusting density, and colorants for aesthetic purposes. This helps to modify the mechanical properties, such as tensile strength and elasticity. It is very important to choose the correct additives and mix them in the right proportions in order to obtain the right performance features.

6. Usage and Application

The performance requirements of the EVA blocks differ very significantly depending on their intended use. In sports applications, cushioning and shock absorption are required to save the athlete from injury. For construction purposes, they have to be durable and able to bear abrasion. Knowing these requirements exactly makes it possible to optimize the performance of the EVA block for each application.

7. Quality Control

Quality control at the production stage is essential for the performance of EVA blocks. Stringent testing and inspection procedures at this stage would enable the detection of any possible flaws or irregularities that could have a bearing on the performance of the block. Indeed, very stringent quality control is implemented by manufacturers like Ideastep to ensure high standards and reliable products.

FAQ

Q: How do I select the right EVA block for my purposes?

A: On density, thickness, and intended use, the sports application requires maximum possible shock absorption and flexibility, while for construction purposes, durability and resistance to various environmental conditions.

Q: What are some of the general usages of EVA blocks?

A: EVA blocks find applications in sports flooring and cushioning, in packaging, and in a myriad of other uses that call for flexibility and durability.

Q: How do environmental factors have an effect on EVA blocks?

A: In service, EVA blocks can suffer degradation from exposure to UV light, temperature changes, and high humidities, which adversely affects their performance. Proper additives and protective measures could help mitigate these effects.