EVA CAD CAM milling blocks are revolutionizing various industries with their precision and versatility. This article explores which industries are best suited for these innovative materials and how they are transforming manufacturing processes.

In recent years, EVA (Ethylene Vinyl Acetate) CAD CAM milling blocks have gained significant attention across various industries. Known for their lightweight, durable, and customizable properties, these materials are reshaping how products are designed and manufactured. But which industries benefit the most from EVA CAD CAM milling blocks? Let’s dive into the sectors where these innovative blocks are making a considerable impact.

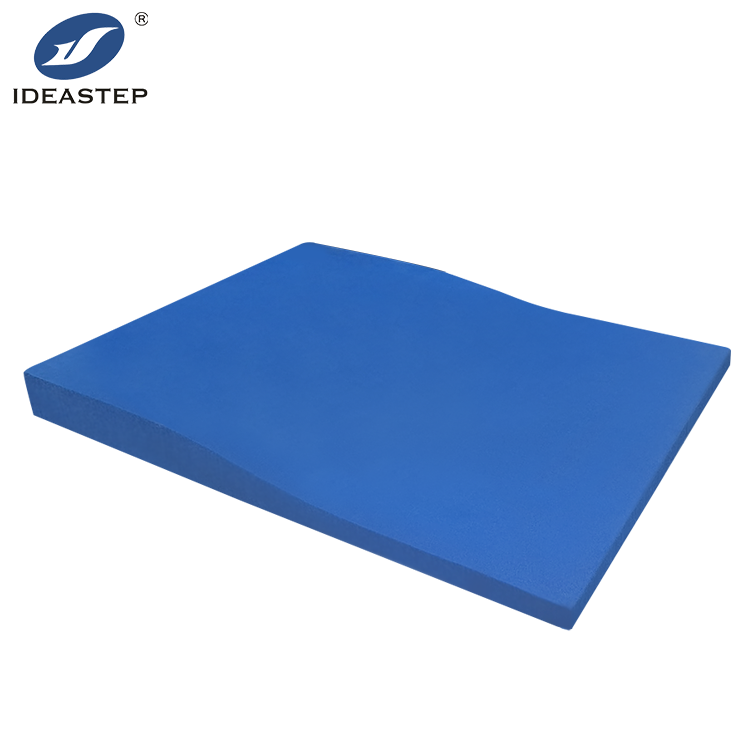

1. Footwear Industry

The footwear industry has been one of the primary adopters of EVA CAD CAM milling blocks. These blocks offer several advantages, including the ability to produce precise and comfortable shoe molds. EVA’s flexibility and cushioning properties make it ideal for creating ergonomic footwear designs. Brands like Ideastep are leveraging these blocks to manufacture high-quality insoles and shoe components that enhance comfort and performance.

2. Sports Equipment

Sports equipment manufacturers are also capitalizing on the benefits of EVA CAD CAM milling blocks. The ability to create custom molds and prototypes quickly and accurately allows for the development of specialized sports gear. EVA’s shock-absorbing and impact-resistant qualities make it suitable for equipment such as helmets, pads, and shoes. Ideastep, for example, uses EVA milling blocks to create protective and performance-enhancing equipment for various sports.

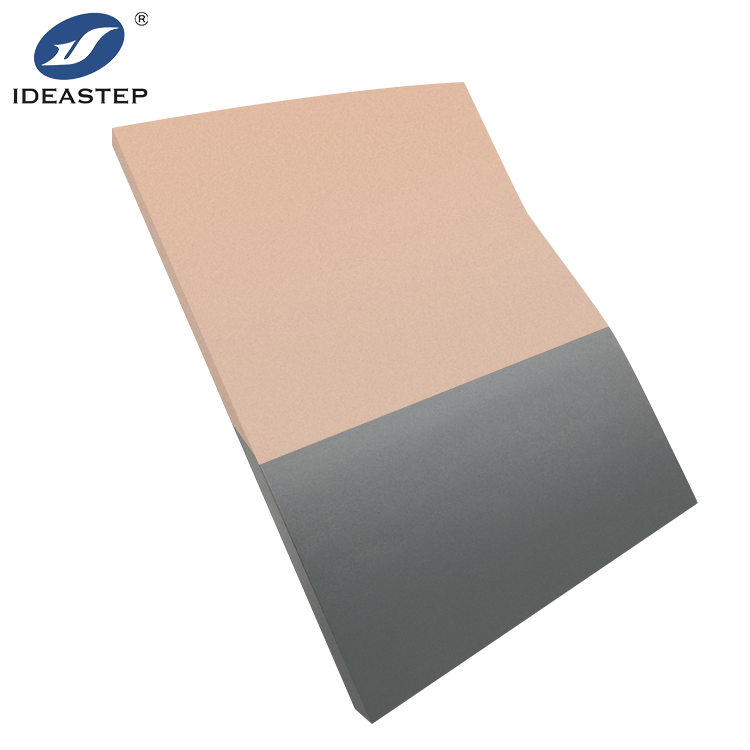

3. Medical Devices

The medical device industry has seen a surge in the use of EVA CAD CAM milling blocks for creating prosthetics, orthotics, and other medical components. EVA’s biocompatibility, cushioning, and lightweight nature make it a preferred material for devices that need to be both functional and comfortable. Ideastep utilizes EVA milling blocks to produce custom-fit orthotic insoles and prosthetic parts that cater to individual patient needs.

4. Automotive Industry

In the automotive sector, EVA CAD CAM milling blocks are used to manufacture various components, including interior parts and cushioning materials. EVA’s durability and ability to be molded into complex shapes make it ideal for producing high-quality automotive parts. Automotive designers use EVA blocks to create ergonomic and aesthetically pleasing interiors that enhance the overall driving experience.

5. Consumer Goods

Consumer goods manufacturers are also exploring the potential of EVA CAD CAM milling blocks. From custom phone cases to intricate household items, EVA blocks offer versatility in design and production. The material’s ability to be easily machined and customized allows for the creation of unique and high-quality products that meet consumer demands.

Conclusion

EVA CAD CAM milling blocks are proving to be a game-changer across multiple industries. Their adaptability, precision, and performance advantages make them a valuable asset in footwear, sports equipment, medical devices, automotive components, and consumer goods. As technology advances and demand for customization grows, the use of EVA milling blocks is likely to expand further, offering new possibilities for manufacturers and designers alike.

FAQ

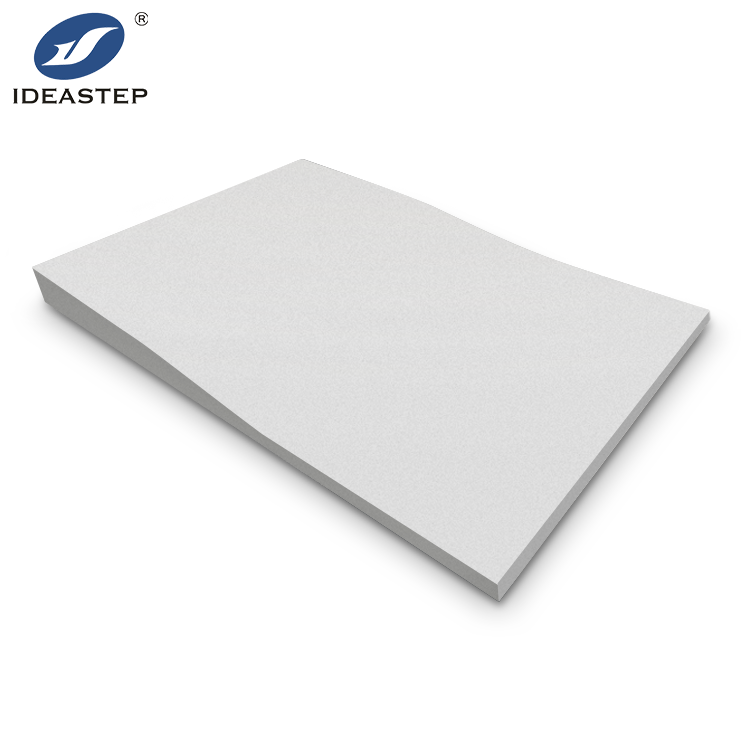

What are EVA CAD CAM milling blocks?

EVA CAD CAM milling blocks are solid blocks of EVA material used in computer-aided design and computer-aided manufacturing (CAD CAM) processes. They are utilized for creating precise molds, prototypes, and components across various industries.

Why is EVA preferred for CAD CAM milling?

EVA is preferred for CAD CAM milling due to its lightweight, durable, and flexible properties. It offers excellent cushioning, shock absorption, and customization capabilities, making it suitable for various applications.

How does Ideastep use EVA CAD CAM milling blocks?

Ideastep uses EVA CAD CAM milling blocks to produce high-quality products such as insoles, sports equipment, medical devices, and automotive components. The blocks allow for precise manufacturing and customization to meet specific requirements.