Obtaining top-notch EVA foam materials is critical for B2B suppliers looking to meet industry standards and customer expectations. This guide provides key insights into finding reliable sources for EVA foam, ensuring product excellence and operational success.

Introduction to Sourcing EVA Foam Materials

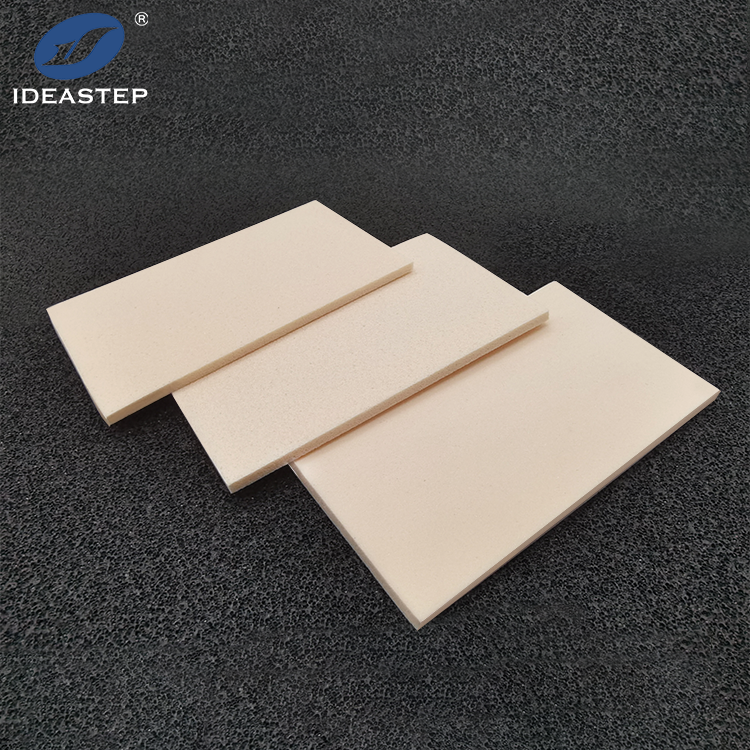

Ethylene-vinyl acetate (EVA) foam is a versatile material used across various industries, including automotive, sports, and packaging. Finding high-quality EVA foam materials is essential for B2B suppliers to ensure product durability, safety, and performance. This guide will walk you through essential steps to locate reliable sources of EVA foam and the key factors to consider in the sourcing process.

1. Know What You Need

Before sourcing EVA foam, it’s crucial to define your specific needs. EVA foam comes in different densities, thicknesses, and qualities, each suited to different applications. Consider the following factors:

- Application: What will the foam be used for? Different applications require different foam properties.

- Thickness and Density: Determine the required thickness and density for your specific use case.

- Certifications: Ensure the foam meets industry standards and certifications for quality and safety.

2. Research Trustworthy Providers

Finding a reliable supplier is key to sourcing high-quality EVA foam. Here are steps to identify trustworthy suppliers:

- Industry Reputation: Look for suppliers with a strong reputation in the EVA foam industry. Check online reviews, testimonials, and case studies.

- Certifications and Compliance: Verify that the supplier’s products meet relevant industry standards and regulations.

- Product Range: Choose suppliers that offer a wide range of EVA foam products to ensure they can meet your specific requirements.

3. Assess Supplier Capabilities

Once you have identified potential suppliers, evaluate their capabilities to ensure they can meet your quality and quantity needs:

- Manufacturing Capacity: Assess whether the supplier can handle your order volume and provide consistent supply.

- Quality Control: Inquire about their quality control processes to ensure the foam meets your standards.

- Lead Times: Confirm the supplier’s lead times for delivery to align with your production schedules.

4. Request Samples and Perform Testing

Before placing a large order, request samples of the EVA foam to evaluate its quality and suitability for your application. Conduct thorough testing to ensure it meets your specifications. Testing should include:

- Durability: Assess the foam’s durability under various conditions.

- Performance: Test the foam’s performance in its intended application.

- Safety: Ensure the foam complies with safety standards and regulations.

5. Negotiate Terms and Conditions

Once you have selected a supplier, negotiate terms and conditions to secure a favorable agreement. Key aspects to discuss include:

- Pricing: Negotiate the best possible pricing based on your order volume and long-term potential.

- Payment Terms: Establish clear payment terms and conditions.

- Shipping and Logistics: Agree on shipping terms, delivery schedules, and any associated costs.

6. Build a Strong Relationship with Your Supplier

Establishing a strong working relationship with your supplier can lead to better service and more favorable terms. Maintain regular communication, provide feedback, and collaborate on quality improvement initiatives. A solid partnership can result in more reliable sourcing and better overall outcomes.

7. Stay Informed about Industry Trends

Keeping up with industry trends can help you stay competitive and make informed sourcing decisions. Follow industry news, attend trade shows, and engage with industry forums to stay updated on the latest developments in EVA foam technology and sourcing practices.

Conclusion

To obtain high-quality EVA foam materials, it is necessary to comprehend your requirements, investigate dependable suppliers, assess their capabilities, and negotiate advantageous terms. B2B suppliers can ensure they obtain high-quality, reliable EVA foam that meets their needs and supports their business success by following these steps.

FAQ

What factors should I consider while sourcing EVA foam?

Consider factors like application, thickness, density, certifications, supplier reputation, manufacturing capacity, quality control, and lead times.

How can I assess the quality of EVA foam samples?

Assess durability, performance, and safety through thorough testing to ensure the foam meets your specifications and industry standards.

Why is it important to build a strong relationship with suppliers?

A strong relationship can lead to better service, more favorable terms, and reliable sourcing, ultimately supporting your business success.