EVA foam is the material of choice for manufacturers looking to improve product durability, comfort, and performance due to its adaptability to a variety of industries.

EVA (Ethylene Vinyl Acetate) foam is notable for its unmistakable mix of shock assimilation, strength, and adaptability. It is a well-known material in a variety of manufacturing businesses due to its flexibility. EVA foam can be used for a wide range of applications, including packaging, sports equipment, medical equipment, and automobile parts. This article examines who ought to contemplate utilizing EVA foam in manufacturing and how various industries can profit from it.

What is EVA Foam?

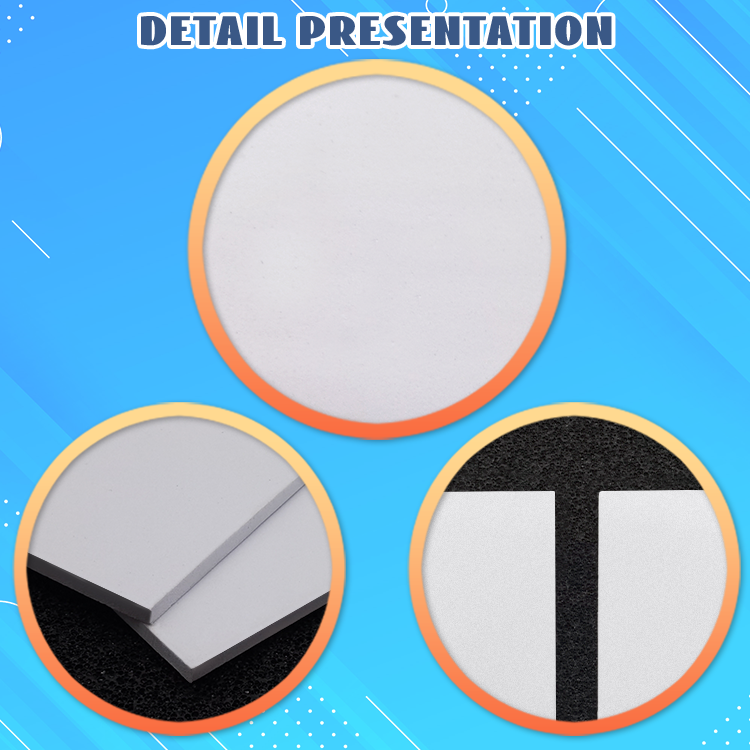

EVA foam is a polymer known for its softness, flexibility, and resilience. It is made by copolymerizing vinyl acetate and ethylene, resulting in a foam material that is not only strong but also light and easy to work with. These properties make EVA foam an ideal choice for industries that require materials capable of withstanding mechanical stress while providing comfort and safety.

Significant Benefits of EVA Foam

- Durability: EVA foam is resistant to wear and tear, making it ideal for products that require long-term strength.

- Shock Absorption: Its excellent cushioning properties make it perfect for products that need to absorb impact, such as sports equipment and protective gear.

- Flexibility: EVA foam is versatile, allowing it to be molded into various shapes and sizes, which is useful for custom applications.

- Lightweight: Despite its strength, EVA foam is lightweight, reducing the overall load of the product.

- Chemical Resistance: EVA foam is resistant to various chemicals, making it suitable for industrial applications where exposure to chemicals is common.

Who Should Consider Manufacturing with EVA Foam?

EVA foam is a flexible material that can be used in a variety of industries. In the following key industries, manufacturers should consider incorporating EVA foam into their products:

1. Automotive Industry

The automotive industry is one of the largest consumers of EVA foam. It’s used for everything from gaskets and seals to interior padding. The material’s shock absorption and durability make it ideal for protecting vehicle occupants and components. Additionally, its lightweight nature helps reduce the overall weight of the vehicle, contributing to fuel efficiency.

Applications:

- Interior Padding: EVA foam is used in car seats, armrests, and door panels for comfort and durability.

- Gaskets and Seals: Its flexibility and resistance to chemicals make it ideal for engine gaskets and seals as well as other automotive components.

2. Footwear Industry

The footwear industry typically makes use of EVA foam, particularly for the production of shoe soles. It is a preferred material for athletic and casual footwear due to its cushioning properties, providing support and comfort. The foam’s flexibility allows it to conform to the shape of the foot, enhancing the comfort and fit of the shoe.

Applications:

- Shoe Soles: EVA foam is the material of choice for midsole cushioning in athletic shoes, providing impact protection and comfort.

- Insoles: It is also used in insoles for additional support and cushioning.

3. Medical Devices and Orthotics

EVA foam has a significant impact on the medical industry due to its hypoallergenic and non-toxic properties. Orthotics, prosthetics, and medical devices frequently incorporate it. The foam’s ability to be easily shaped and its shock-absorbing attributes make it ideal for creating comfortable and supportive medical products.

Applications:

- Orthotics: EVA foam is used in custom orthotic devices to provide support and correct foot alignment.

- Prosthetics: Due to its cushioning properties, it is also used in the production of prosthetic limbs.

4. Sports Equipment

EVA foam is a popular material in the sports industry, where it is used to manufacture a variety of equipment, including protective gear and padding. Its shock-absorbing properties help protect athletes from injury, making it a key component in sports equipment design.

Applications:

- Protective Gear: EVA foam is used in helmets, pads, and guards to absorb impact and protect athletes.

- Mats and Flooring: It is also used in gym mats and flooring to provide cushioning and prevent injuries during workouts.

5. Packaging Industry

The packaging industry uses EVA foam to protect products during shipping. It is ideal for packaging fragile items due to its lightweight and shock-absorbing characteristics. EVA foam can be easily cut and shaped to fit around products, providing a custom protective solution.

Applications:

- Protective Packaging: EVA foam is used to create custom inserts for packaging fragile or valuable items.

- Case Linings: It is also used to line cases to protect equipment and tools.

Conclusion

EVA foam is a versatile material with numerous benefits across various industries. Manufacturers in the automotive, footwear, medical, sports, and packaging industries should consider incorporating EVA foam into their products to enhance durability, comfort, and performance. By understanding the unique properties of EVA foam and its wide range of applications, businesses can make informed decisions about integrating this material into their manufacturing processes.

FAQ

Q1: Is EVA foam safe for use in medical devices?

A1: Yes, EVA foam is non-toxic, hypoallergenic, and widely used in medical devices and orthotics, making it safe for such applications.

Q2: Can EVA foam be customized for specific applications?

A2: Absolutely. EVA foam is highly flexible and can be molded, cut, and shaped to meet specific manufacturing requirements, making it suitable for custom applications.

Q3: What are the advantages of using EVA foam in footwear?

A3: EVA foam provides excellent cushioning, comfort, and support, making it ideal for use in athletic and casual footwear, particularly in shoe soles and i