Material thickness assumes a pivotal part while choosing EVA sheets for different undertakings. The right thickness guarantees ideal execution, solidness, and cost-proficiency, making it fundamental to comprehend its effect on your particular application needs.

Introduction to EVA Sheets

EVA (Ethylene Vinyl Acetate) sheets are generally utilized in different enterprises because of their adaptability and helpful properties. These sheets are produced using a copolymer of ethylene and vinyl acetate, which bestows adaptability, sturdiness, and effect opposition. The thickness of EVA sheets can altogether impact their presentation and reasonableness for various applications.

Thickness Matters When Choosing EVA Sheets for Your Projects

The thickness of the material is a crucial consideration. The strength, flexibility, and overall performance of EVA sheets are all impacted by their thickness. If you know how thickness affects these factors, you can make better choices and choose the right material for your needs.

Influence on Strength and Durability

Quite possibly of the main element impacted by material thickness is the strength and solidness of EVA sheets. Thicker EVA sheets commonly offer more noteworthy protection from mileage, influence, and actual pressure. This expanded strength makes them appropriate for applications that include weighty burdens, continuous use, or cruel circumstances.

For instance, in development or auto ventures, thicker EVA sheets are frequently utilized for deck, protection, and padding. Their upgraded toughness guarantees that they can endure the anxieties of large equipment and high-traffic regions, lessening the requirement for successive substitutions and upkeep.

Flexibility and Usability

While thicker EVA sheets offer predominant strength, they might be less adaptable contrasted with more slender sheets. For applications that necessitate simple molding or shaping, EVA sheets’ flexibility is crucial. EVA sheets that are thinner can easily be cut, shaped, or formed to fit particular designs and contours because they are typically more pliable.

In contrast, obtaining the desired shape from thicker sheets may necessitate additional processing or cutting tools. In this way, it’s critical to adjust the requirement for sturdiness with the prerequisites for adaptability in view of the planned application. For example, more slender EVA sheets are frequently liked for applications like defensive cushioning, where adaptability and simplicity of establishment are fundamental.

Thermal Insulation and Comfort

The thickness of EVA sheets likewise influences their warm protection properties. Thicker sheets give better protection against temperature changes, making them appropriate for applications requiring warm insurance. This property is especially significant in businesses like development and auto, where temperature guideline can affect execution and solace.

For example, thicker EVA sheets can be utilized in car insides to give protection against outer temperature changes, upgrading traveler solace. Essentially, in development, thicker sheets can be utilized in protection frameworks to further develop energy proficiency and diminish warming or cooling costs.

Cost Considerations

Material thickness likewise assumes a part in the expense of EVA sheets. Due to the increased amount of material used, thicker sheets typically cost more than thinner ones. However, the longer lifespan and lower maintenance requirements of thicker sheets may offset the higher initial cost.

While choosing EVA sheets, it’s fundamental to consider the drawn out advantages and potential expense reserve funds related with thickness. Thicker sheets may initially be more affordable, but thicker sheets may provide superior durability and performance, resulting in lower overall costs over time.

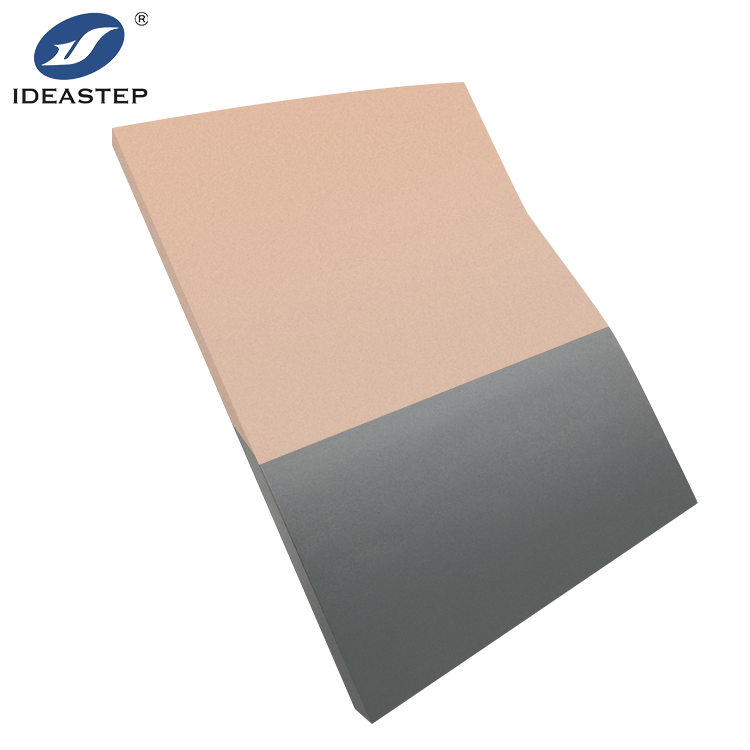

Applications of Different Thicknesses

The thickness you choose depends on your project’s specific needs. Here are a few normal applications and the run of the mill thicknesses utilized:

- Comfortable Cushioning: More slender EVA sheets (e.g., 5–10mm) are frequently utilized for padding and cushioning in different items, giving solace and effect obstruction.

- Flooring and Insulation: Medium to thick EVA sheets (e.g., 15–30mm) are utilized for protection and ground surface applications, offering sturdiness and warm insurance.

- Heavy-Duty Applications: Thick EVA sheets (e.g., 50mm or more) are utilized in substantial applications, like modern deck and car parts, where strength and sturdiness are essential.

Choosing the Right Thickness for Your Needs

The following factors should be taken into consideration when choosing the right thickness for your EVA sheets:

- Application Requirements: Decide the particular requirements of your task, including strength, adaptability, and warm protection.

- Environmental Conditions: Consider the conditions under which the EVA sheets will be used, such as physical stress or extreme temperatures.

- Cost versus Benefit: Gauge the underlying expense against the possible long haul advantages of thicker sheets, including solidness and decreased upkeep.

Conclusion

Material thickness is a critical thought while purchasing EVA sheets for your ventures. It influences strength, adaptability, warm protection, and cost. You will be able to make educated choices and select the appropriate EVA sheets for your particular requirements if you comprehend how thickness affects these aspects. Whether you require sturdiness, adaptability, or warm insurance, choosing the suitable thickness will upgrade the exhibition and productivity of your ventures.